-

Posts

307 -

Joined

-

Last visited

-

Days Won

2

Content Type

Forums

Events

3D Prints

Posts posted by ataraxis

-

-

@Catlord: What exactly do you mean? It's just the fans, right? Personally I have still the original one installed since I hadn't time to give the others a try. Feel free to commit your experience too if you have finished the installation.

-

Yeah, we saw both problems in fact, Yesterday I set it to weekly and it printed way too close - altough we leveled one Minute before.

-

That's what I would prefer too, but I don't think this is going to happen any time soon 🙂

I know this approach is more expensive, but it does at least work - no matter which firmware is installed,

I can easily wait for some seconds/minutes if the print doesn't fail then.

Btw, the difference is not THAT big (around 0,2 seconds on my current 120 layer print).

I suggest to add a dropdown field named "z Offset method" or something like that, where you can decide which ob both methods you want to use, something like:

1) `classic G92 (fast but not supported by some UM firmwares)`

2) `global offset adding (slow but robust)`

You could then preselect one of both types depending on the gcode flavour.

-

I forked the plugin since the maintainer @ahoeben told me he is not going to change the plugin to be compatible to the new firmware. here you find a compatible one: https://github.com/atar-axis/Cura-ZOffsetPlugin

This fork does not use G92 but is adding the offset to every G0/G1 Z value.

I opened a PR on the original project: https://github.com/fieldOfView/Cura-ZOffsetPlugin/pull/5

Tested on UM3 with latest fw 5.2.?, works.

-

@ahoeben maybe you should comment at the other Thread too, i reported the Bug and will Post it there If i get an answer

-

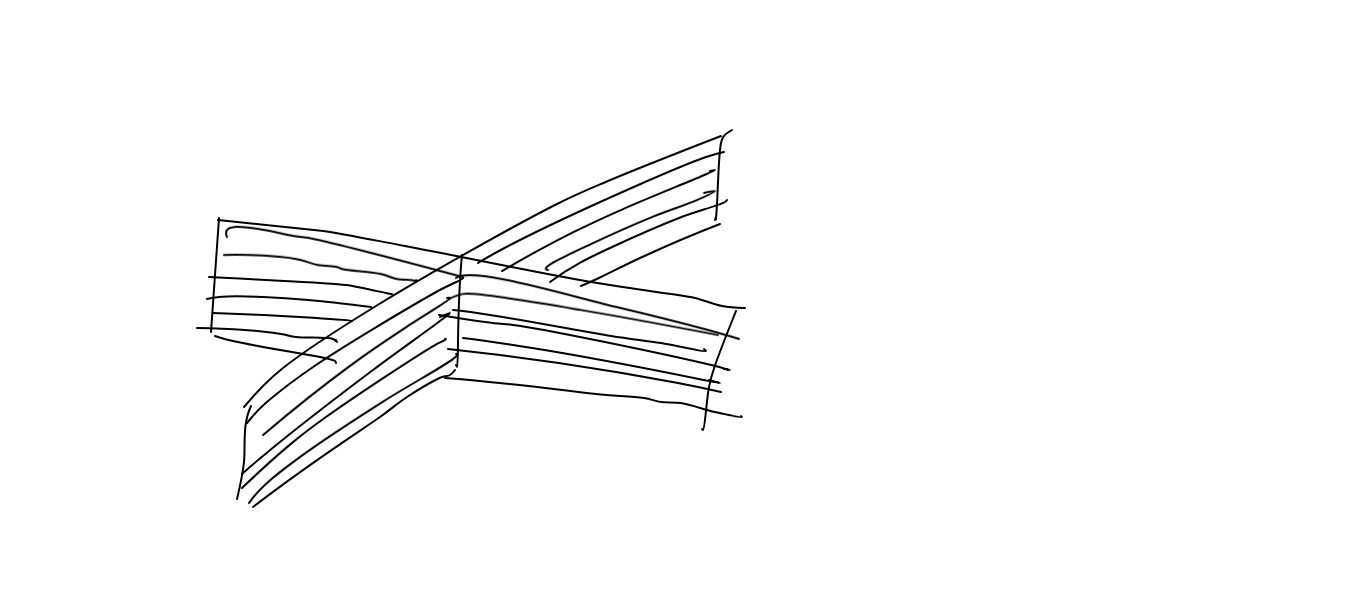

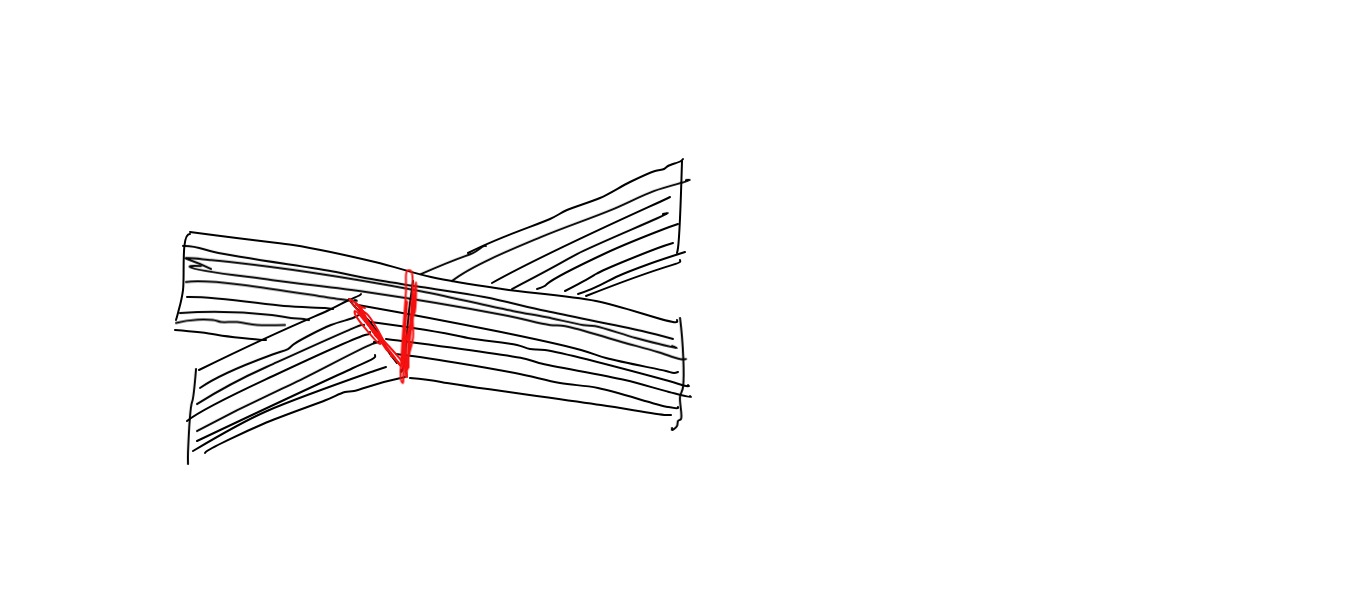

This is how it looks like, btw:

-

I fear this plugin doesn't work anymore on FW 5.2, take a look here:

-

nope, auto bed leveling is active on our printer - it levels before every print

-

-

-

Hi there!

We have installed an Buildtek Flexplate on our UM3 @work.

The problem with this setup is that automatic leveling does stop a bit too late so that the

first layer is pushed too hard into the bed.

Up to now we used the following startscript to increase the first layer height:

G91 ;Relative movement G0 F15000 Z0.2 ; Move down the plate a bit G92 Z0 ; Tell the printer that this is the zero position G90 ;Disable relative movementUnfortunately this doesn't work anymore since the last Update!

Why?

Thank you in advance,

ataraxis

-

For sure, the problem is that we are using a magnetic mounted flexplate, which is - in my eyes - prone to small deformations. We therefore level actively before every print 🙂

-

Thing is, I am not the only one who is using this printer, would be great to let the printer handle this additional distance himself. Otherwise everyone who wants to print has to add this Startcode and keep it up to date.

-

Okay, the startcode works,... there was just a non-printable Unicode sign in it 😄

Anyways, is there another way like the mentioned json files?

-

Hi there!

We have an UM3 @work and we have installed a BuildTek flex plate on it.

Active leveling works again after inserting a nut and a spacer on the screw at the backpanel.

The problem is, that the buildplate is relatively soft, therefore the nozzle pushes a bit too deep while measuring the distance.

I would like to compensate that by lifting the nozzle to Z0.1 before the print starts.

I tried to add the following start code in CURA:

G91 ;Relative movement G0 F15000 Z0.2 ; Move down the plate a bit G92 Z0 ; Tell the printer that this is the zero position G90 ;Disable relative movementUnfortunately the printer does not do anything then... It heats up, tells me he is now starting the print but nothing happens.

Where is the problem with the start code and is there maybe another way to change the "start height" - via the dev mode and the json files maybe?

Thanks!

-

@neotko Any news on that? :) If you do not have spare time at the moment: I would also do it myself if you would share with me what you have :P

-

One can use the M122 command when TMC DEBUGGING is enabled at the sourcecode - it's quite simple.

Unfortunately it looks like StallGuard2 is more like a "EndStop replacement", it does not work on low velocities like at the feeder (https://www.trinamic.com/technology/adv-technologies/stallguard/).

-

anyone ever tried to display the current stall value (at the display or sth like that) using marlin?

-

ups, I forgot to mention: UMO with heated bed update ?

should be the same as the UMO+ therefore, right? :)

-

1

1

-

-

Hey neotko, thank you very much for that! I am owning an UMO, therefore I will have to modify it a bit anyway I guess :)

-

Oh man, that's really sad... I was really impressed of his creative drive.

But to be honest: I do not really understand why they have deleted his designs - they would have been some kind of legacy to his community in my eyes. -

-

looks like I am not the only one, I found a lot of others who complain about the same issue printing PETG, e.g. here: https://shop.prusa3d.com/forum/others-archive--f66/petg-and-renticular-fill-t14618.html

changing from "grid" to "lines" improved the infill print quality extremely,

what also helped is to print even the outer walls at the same speed as the rest.yeah - workarounds and hacks, but at least it works...

EDIT:

I finally switched to Simplify3D instead of Cura - there I use the honeycomb infill which does not intersect. Solved all my Colorfabb XT problems at once. Lovely software, expensive but worth it! Damn, I realy enjoy that extremely fast visualisation - my mobile computer isn't the fastest and CURA was always extremely slow.

-

STEP-BY-STEP: Installation of E3D-v6 on UMO

in Third party products & modifications

Posted

> because you wrote 'to be continued"

Yeah that's because of the fans :)

I installed the E3D because I am printing ABS from time to time and because I wanted to switch to a full metal hotend because of the wear of the original one. I never printed something with carbon filaments, so I cannot tell you anything about how good or bad the E3D behaves there.

There are two downsides I recognized so far:

1) The hotend fan is noisy (the small one)

2) It's sometimes hard to remove the filament because the melted platics get stuck at the cold end of the hotend (haha :D)

I would say it was worth the time and money I invested anyway, I printed really a lot with ABS.

Cheers