f1oat

-

Posts

8 -

Joined

-

Last visited

Content Type

Forums

Events

3D Prints

Posts posted by f1oat

-

-

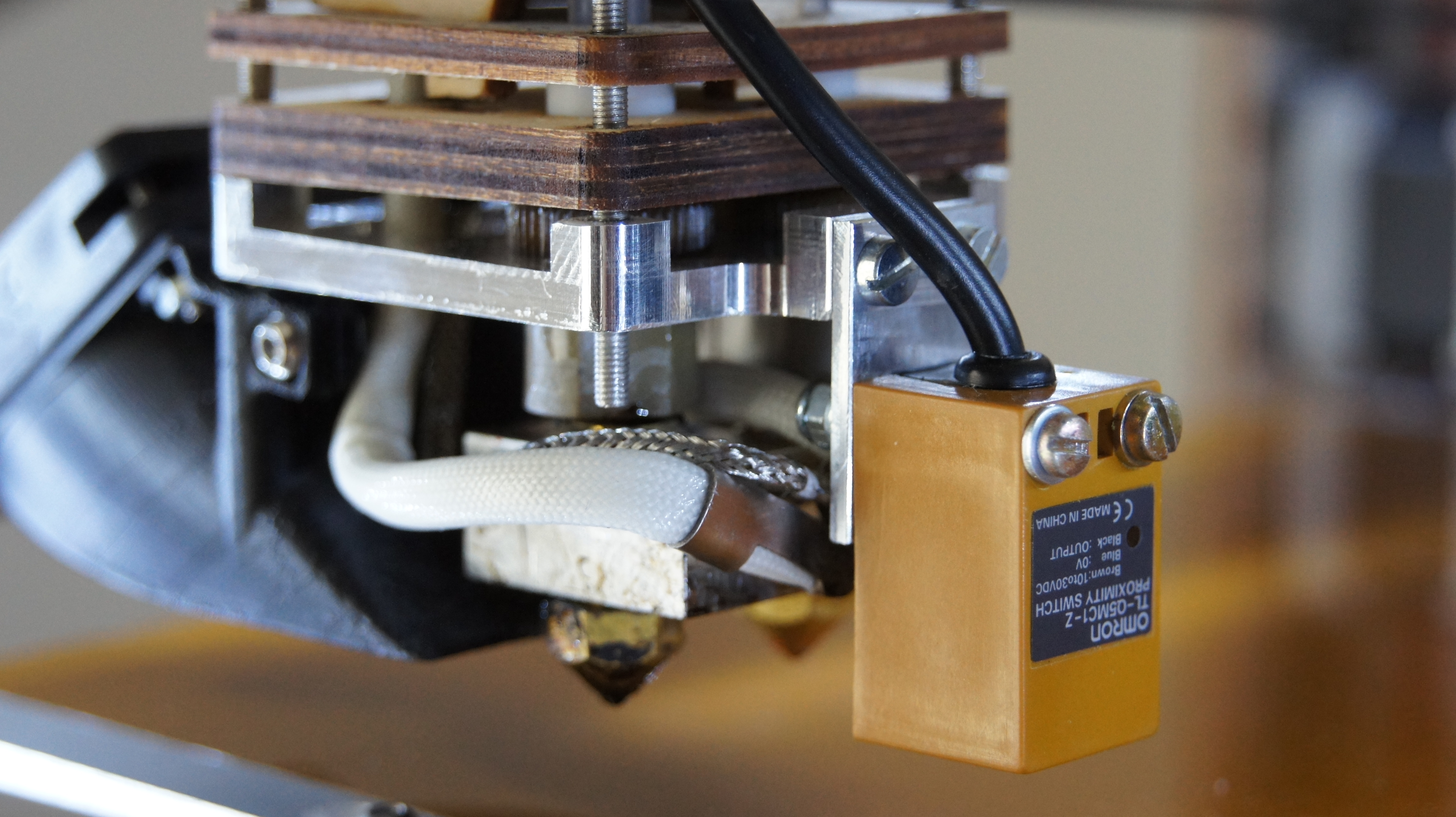

I have designed a modified hot-end holder for easy installation of a TL-Q5MC1-Z induction sensor. So far, I am quite happy of the performances: not more disappointing print coming from improper leveling !

Full detail here, including a video of the project.

Frederic.

-

1

1

-

-

I have just received my Omron TL-Q5MC1-Z proximity sensor.

Rated for 10to30 VDC power supply, but works well down to 2.5V, including the embedded LED.

Measured sensing distance is about 5mm for steel, but less than 2mm for the aluminum plate.

Looks nominal according to page 6 of http://www.ia.omron.com/data_pdf/cat/tl-n_tl-q_ds_e_11_1_csm468.pdf

Unfortunately that is not compatible with my setup where I have a 3mm glass plate !

I need to think more about this issue: either I will have to add a thin plate of steel between the aluminum bed and the glass, or I will have to find another sensor.

Frederic.

-

Hello

I experience the same issue after adding a heated bed to my UM1.

Please, could you describe your "freewheeling circuit" solution.

Thanks.

Frederic.

-

Try to adjust your PSU to 19 or 20V.

As far as I know, this is the recommended setting for this heated bed. Then, the current will ve around 10A and should be within the power dissipation specs of your PSU.

Frederic

-

Thats basically it, I think the end result is quite nice, and will be even nicer with the cable chain...

I have just installed my Jason HK heated bed.

I have printed the cable chain from https://www.youmagine.com/designs/heat-bed-wire-clip-for-um-original-remix to accommodate with the 4 cables coming with the kit. I am quite happy with the result:

I use a common 24V 15A power supply both for the heated bed and the original electronics. Everything went smooth except some random clicks of the knob when the heated bed is switched on. I suspect some EMI coming from the high current and disturbing the gray ribbon cable of the Ulticontroller. I have solved the issue with some filtering in Marlin firmware.

-

A plugin could do the job. Please feel free to write one and to share it if you like... :smile:

Thank you. Time for me to learn how to write a plugin !

Stay tuned.

Frederic.

-

Hello,

I would like to print in dual extrusion mode with PLA in extruder #1 and Flexible PLA in extruder #2. But the two materials require different parameters (slow print speed and no retraction for flexible PLA).

Is there any option in Cura to have fully independent settings for each extruder ?

May be that can be done with a custom plugin ?

Frederic.

Température et mise en sécu...

in Français

Posted

Sur une UMO, j'ai déjà eu le pb plusieurs fois.

A chaque fois résolu en resserrant les vis du petit domino vert sur la tête (celui qui fait la connexion avec les 2 fils du thermocouple).

Frédéric.