-

Posts

3,778 -

Joined

-

Last visited

-

Days Won

76

Content Type

Forums

Events

3D Prints

Posts posted by ultiarjan

-

-

the reason it's a 0.6 is because it's meant to print materials filled with particles, like carbon, glass, or various metals. While possible with a 0.4 , the risk of getting a clogged nozzle is much lower with a 0.6.

I usually print Nylon on glass with (very little) glue stick, diluted to a very thin layer, using a damp paper towel.

-

While I don't know this specific material, I print various flexibles on the Ultimaker adhesion sheets (cleaned with alcohol between prints) and that works fine, so might be worth a shot.

-

I have no idea how complicated this would be, but @ahoeben would extruder settings synchronization be possible with a plugin ?

-

https://github.com/Ultimaker/Cura/issues/2048I asked for this before... but it has never made it.... would still be a good improvement but I don't feel its very useful to ask againsee below 😃

-

can you explain a bit more, or beter show a picture? do you still use the original small black feeder?

-

link;

-

1

1

-

-

I'm not sure if they generated an STL or just directly generated the G-code for the test prints, but they didn't use a slicer for sure as there is non available...

After a quick read of the article my interpretation would be that there is no real practical/mechanical reason to implement Schwartz P or D into Cura as they do not outperform the already implemented Gyroid infill.

They do look cool though 🙂

-

1

1

-

-

Not atm, but you could always ask the guy who brought us the gyroid infill for cura; @smartavionics

interesting read I found;

-

2

2

-

-

6 hours ago, NBull said:

I would disconnect the bowden at the print head and some of the wire clips. so you can pull the bowden off the filament piece. then manually heat the printhead til the filament can be pulled out. Assuming theres still a bit of filament left over the print head when the bowden is removed. so you have something to pull on.

(Disclaimer, its a long time since i have worked with the u2, so there might be a better way to do it)

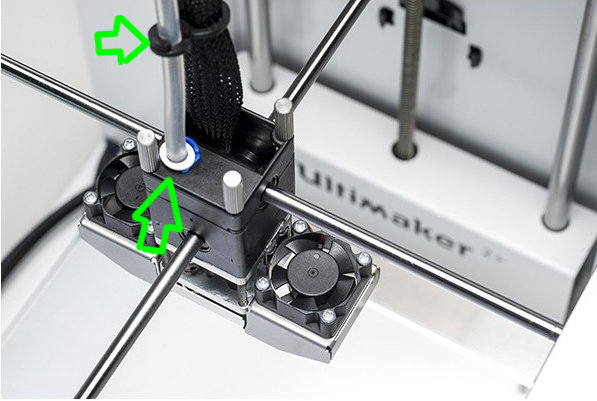

to be clear; take out the horseshoe clip (the blue thingy) then push down on the white thingy while pulling out the bowden tube.... Works the same on the feeder side of the tube...

-

And you should be proud !!! you rock !!!

Some of your work should really be standard incorporated in Cura, f.e the sidebar plugin is 1000x better than the default gui.

Thanks for making Cura a lot nicer to work with.

-

1

1

-

-

8 hours ago, gr5 said:

Don't do the QR on the UM2+. It's twice as expensive and not as good. The DDG is much easier to install - it drops right in.

I don't agree, I prefer the QR as it's easier to clean the gears. I run one on an Ultimaker2 for years and it just works. Would recommend it.

-

And to add, some of my project files created in cura 4.3 all with a specific printer make cura crash, funny thing is the custom printer gets added before cura crashes. Did send the crash reports.

-

He Robert, welcome.

You made me curious, now I want to see the rain>electricity thing....

-

2 hours ago, NBull said:

Extrusion Width can also help since it forces the layers to bond more eg. 0.48 on a 0.4 nozle 120% increase

This seems counter productive to me, as the lines will also be printed 0.48 apart from each other. I would just keep 0.4 but increase flow % and temp a bit.

If you increase flow, and need working threads, you may need some negative "horizontal expansion" (in CURA's shell settings) to compensate

-

not a complete answer... but here's the pinout ;

-

1

1

-

-

On 11/3/2019 at 6:47 PM, Link said:

Thanks, just checked the price of the CC core !, over £320 !, ouch, that's expensive!, I am sure it used to be less than this ?!

it was always just below 300 euro i think. Probably the effect of the pound not doing to well.....

-

for curious people that don't want to install the beta, you can also just download the zip

https://github.com/Ultimaker/Cura/releases/tag/4.4-beta-pre-release

And check the new profiles (open fe in notepad++) in:

Downloads\Cura-4.4-beta-pre-release.zip\Cura-4.4-beta-pre-release\resources\intent\ultimaker_s5

-

1

1

-

-

here's some inspiration for you ....

-

-

-

2

2

-

-

-

My gut feeling says it's cura and not something mechanically... did you use a standard profile? which one? changed any settings?

-

On 9/2/2019 at 2:27 PM, Hertz said:

I do like the UM2 intuitive scroll-wheel and screen, and my wife knows how to use it.

Sounds to me you're just looking for an excuse to upgrade to the duet 😛 , you know your wife will learn how to use it in just a few minutes as it's super easy, specially with the "print to duet" plugin in cura.... Also, you'll have the same workflow as on the other machine.. The duet is just the better option imho..

-

For Ultimaker2 for sure, many people are using f.e. the alternative "tinker" firmware for there machine.

https://github.com/TinkerGnome

I'm not sure what you want to archieve, but you may also want to have a look at Duet3D electronics for printers (I use it in 2 Ultimaker machines) where you can modify many parameters without having to recompile firmware...

https://duet3d.dozuki.com/#Section_Firmware

-

1

1

-

Bearing type for the knurled wheel

in UltiMaker 3D printers

Posted

Think it's this one; (ultimaker part 8247). Don't think Ultimaker resellers will have it on stock, but you can try @MakerPoint they may have it.

picture of other feeder parts here;