-

Posts

2,774 -

Joined

-

Last visited

-

Days Won

61

Content Type

Forums

Events

3D Prints

Posts posted by tinkergnome

-

-

I think these lines are from a different documentation.

There's a separate installation guide for the UM3:

https://support.bondtech.se/Guide/03.+QR+for+Ultimaker+3/14?lang=en

But...

The "QR Ultimaker 3 Kit" comes with its own stepper motors, there should be no need to change the rotation direction?

If you use a different setup... the direction of stepper motors can usually be changed by swapping one pair of the four cables.

-

The printer definition is called "Mark2 for Ultimaker2".

It's still included in a default installation of Ultimaker Cura (as far as i can see).

It uses gCode-flavor "Marlin"

-

21 hours ago, ingo46 said:

Hallo,

ich benutze CURA 4.10. Ich habe versucht über den MarketPlace an "Generic-HIPS" zu kommen. Hat aber nicht funktioniert. Gibt es eine andere Lösung, um HIPS zu drucken?

Ingo

Man ist doch nicht auf den Marketplace angewiesen, oder?

Ich würde (in Cura) einfach mit dem ABS-Profil starten, evtl. die Drucktemperaturen etwas anpassen - kommt darauf an, was der Hersteller vom HIPS so vorschlägt.

Wenn es um einen der oben genannten Drucker geht, dann am Drucker auch ABS auswählen und los gehts.

-

22 hours ago, GregValiant said:

My printer works fine.

Right - there's no need to rant.

Creality printers are working great.

Just replace electronics and firmware (Duet3D), all fans (Noctua), feeder (Bondtech) and hotend (E3D) - and you get a silent and reliable machine!

😛-

1

1

-

-

4 hours ago, JvH said:

Can you tell me where I can read more about the mentioned possibility via SSH to give this command. That sounds like the solution to this problem.

Well, the firmware passed through a few iterations since the good old UM3, but here is a comprehensive description. And developer mode still works in the same manner:

-

Von "Creo" hab ich noch nie zuvor gehört, ich kann es deshalb nicht vergleichen...

Eine kostenlose (und cloud-freihe) Möglichkeit ist FreecAD: https://www.freecadweb.org/

-

This should solve it:

-

1

1

-

-

On 7/29/2021 at 6:15 PM, Ch3vr0n said:

which to my understanding (regular fan speed at layer 4) means no part cooling until layer 4 (layers 1-3) starts. Under "Speed i have "Number of slow layers 4" (which equal my bottom layer count). Yet despite those settings, part cooling STILL KICKS IN at Layer 2 (albeit at a 33% according to octoprint) but the fan is visbily spinning. This is causing bed adhesion problems for me, despite using brim (and 3DLac). Am i missing something?

I think you can't achieve this with (only) the fan settings.

With the settings from above:

- Cura starts with "Initial Fan Speed" at the first layer, and this setting is used for the first layer only

- fan speed increases gradually on each subsequent layer until "regular Fan Speed" is reached at the layer that is configured as "Regular Fan Speed at Layer..."

It's well explained in the manual:

https://support.ultimaker.com/hc/en-us/articles/360012613199-Cooling-settings

You want to change the regular fan speed (or other settings) at a certain height? -> Use a mesh modifier. That's the only way at the moment as far as i know.

-

11 hours ago, JosR said:

does anybody know if it is possible to send a Pause command over a local network?

One can use the API of the printer in a local network. The following topic contains a working example:

-

5 hours ago, IrvineCAGuy said:

Is the UM2 being supported and/or talked about??

Welcome @IrvineCAGuy, this is a community forum - rich on content created by users of Ultimaker products - so... questions are always allowed 🙂 (there are only some simple rules to respect as always).

-

If you have a need for spare parts or official support - you can contact a reseller of your country. There's a list here:

https://ultimaker.com/resellers/

-

The general UM2 support pages (for the basics):

https://support.ultimaker.com/hc/en-us/sections/360003504360-Ultimaker-2

-

for everything else - feel free to ask.

Most of the time you'll get at least some hints or field reports back.

Enjoy the forum!

-

If you have a need for spare parts or official support - you can contact a reseller of your country. There's a list here:

-

12 hours ago, gr5 said:

Where did he get the witbox hex file?

Because you asked: "MarlinWitbox.hex" is included in the Cura firmware resources. It's there for ages and the comment says:

==MarlinWitbox== The MarlinWitbox.hex firmware is build from https://github.com/bq/Marlin and released under GPLv3

No more details though 🤷♂️

-

Das ist mit einem sogenannten "Cutting Mesh" möglich (einfach für den so markierten Bereich einen anderen Extruder auswählen).

Hier ist die Möglichkeit beschrieben:

-

1

1

-

-

20 hours ago, zerspaner_gerd said:

Aber das Verständnis fehlt mir dafür schon z.B. Warum steht in den Material Profilen eine Standby Temp von 175C und in der Settingsleiste 100C.

OK, warum die Temperaturen fachlich so definiert wurden, kann ich auch nicht sagen. 🤷♂️

Ich kann nur versuchen, es technisch nachzuvollziehen.

Ich glaube hier müssen wir uns erstmal einigen, was ein "Profil" ist. In der Cura Programm-Oberfläche wird nur ein (kleiner) Teil der Einstellungen überhaupt angezeigt.

Wenn ich von Profilen rede, meine ich immer die Konfigurationdateien im Programm-Ordner (bzw. im AppImage - je nach Betriebssystem). Da haben wir unterhalb von "resources" alles mögliche dabei: xml, json, cfg/text

Cura baut sich beim Start einen kompletten Katalog aus diesen Dateien und angezeigt wird am Ende für die Druckparameter immer der Wert mit der höchsten Priorität.

Material steht dabei ziemlich weit unten im Stapel, sehr oft ergibt sich deshalb durch die ausgewählte Kombination aus Drucker, Variante und Qualität einfach etwas anderes.

Jede Ebene ist wie ein Formular, wo nur bestimmte Werte ausgefüllt sind und der Rest der Seite ist transparent. Davon liegen in einer festgelegten Reihenfolge viele Lagen übereinander. Dann schaut man von oben drauf- und voila - da hast Du die Setting-Leiste.

Ob man von den unteren Lagen dann überhaupt noch etwas sehen kann, hängt eben stark davon ab, was alles darübergelegt wurde...

Schau mal z.B. hier rein:

[...]\resources\materials\generic_pla.xml.fdm_material

Dann wirst Du sehen, das es im Materialprofil für "Generic PLA" nicht nur eine allgemeine Standby-Temperatur gibt, sondern das es darin auch "Spezialisierungen" für bestimmte Drucker und Düsendurchmesser geben kann. Damit fängt es schonmal an...

Was dann in der Settingleiste davon noch zu sehen ist, hängt aber außerdem vom darübergelegten "quality" - Profil ab. Für "Generic PLA", "Normal"-Auflösung und "Ultimaker 3" wäre das dann dieses hier:

[...]\resources\quality\ultimaker3\um3_aa0.4_PLA_Normal_Quality.inst.cfg

Das "quality"-Profil hat eine höhere Priorität und gewinnt immer! 🙂 (*)

In diesem Beispiel (und für praktisch alle Ultimaker-Drucker) ist es deshalb völlig "wurscht", was als Standby-Temperatur im Materialprofil steht.

Für Ultimaker-Drucker würde ich deshalb das hier auch unterschreiben...:

19 hours ago, Smithy said:Materialprofile werden überbewertet meiner Meinung nach....

Es muss aber halt nicht für jede Drucker / Nozzle / Material - Kombination ein spezialisiertes Profil geben.

Die Einstellungen aus der Material-Datei kommen dann zum Tragen, wenn die "quality"-Datei (*) für die ausgewählte Kombination aus Drucker und Material keine Angaben dazu enthält.

Ein Beispiel für PLA wäre diese Kombination hier:

[...]\resources\quality\tronxy\tronxy_0.2_PLA_extra.inst.cfg

(*) ja, ich weiß, es wird nicht immer das "quality" - Profil gewinnen. Es kommen dafür auch "variants", "intent" und "extruders" in Frage... (und wahrscheinlich noch ein paar andere).

Aber irgendwo muss man anfangen, sonst wird man ja verrückt... 🙂

Ich hoffe, es hilft trotzdem, das Rätsel zu lösen - es steckt eine einfache Logik in diesem Stapel-System!

-

1

1

-

-

12 hours ago, zerspaner_gerd said:

Naja so einfach ist es nicht

- es gibt keine Level Temperatur

- Und ob jetzt die Standbytemp aus der Material Datei oder aus den gcode/ufp Datei kommt ist nicht klar

- Bei den aktiven Extruder wird scheinbar gleich die Drucktemperatur angewählt also nichts von Standby, und wo er die herholt ist für mich auch nicht klar (gcode/ufp Datei oder aus Material Dateien)

- Und bei einen Single Druck wo der 2te Extruder deaktiviert ist wird dieser auch geheizt und eine Temp gewählt

Das ist zwar der falsche Thread - aber trotzdem noch ein paar Gedanken dazu...:

zu 2.

Bei einem "single"-Druck stehen im gcode-Header keine Angaben zum ungenutzten Extruder drin. Also kann die "Level"-Temperatur gar nicht aus dem gcode entnommen werden.

Und... "Level Buildplate" kann auch direkt am Drucker gestartet werden, komplett unabhängig von Druckaufträgen.

Für diesen Schritt ist nur interessant, welches Material beim "laden" am Drucker ausgewählt wurde (manuell oder per NFC), da bin ich ziemlich sicher.

zu 4.

Ich benutze das "Active-Leveling" nicht, aber wenn das Material aus dem deaktivierten Extruder entfernt ist (mit "unload material"), dann sollte der während der Messung auch kalt bleiben (oder hat sich das geändert...?)

-

19 hours ago, zerspaner_gerd said:

Ich selber arbeite nicht mit den Material Profilen und trage meine werte direkt in der seitlichen Settingsliste ein, mir ist da immer ein Rätsel welche Wert den letztendlich verwendet werden.

Damit Du nicht immer rätseln musst - das ist ganz gut dokumentiert.

Sämtliche Druck-Einstellungen in Cura stammen aus einem Stapel mit einer ganzen Reihe von Schichten. In jeder "höheren" Schicht kann der "weiter unten" festgelegte Wert manipuliert (mit Berechnungs-Formeln) oder komplett überschrieben werden. Und der Wert, der jeweils oben ankommt, wird in der (seitlichen) Liste angezeigt und dann auch für den Druck verwendet.

Wenn man nicht vorhat, eigene Drucker- und "quality"-Profile zu entwerfen, ist letzteres auch das einzige, was man braucht.

Das ganze System ist einigermassen komplex - aber auch sehr flexibel.

Es muss auch nicht jede einzelne "Schicht" existieren - "Intent"-Profile gibt es z.B. nur für die neueren Ultimaker-Drucker.

Wen es interessiert: hier ist beschrieben, wie der ganze Stapel aufgebaut ist:

https://github.com/Ultimaker/Cura/wiki/Profiles-&-Settings

-

1 hour ago, Rharrison said:

I was wondering if it would be possible to build the support structures in PLA which is reliable and print the final few layers before contact in PVA

With Cura - the "support interface" can be used to achieve this.

Basically - "Enable Support Interface" and use the PVA-Extruder only for this specific part of the support - something like this:

A link with some more pictures:

https://mathgrrl.com/hacktastic/2018/03/dissolvable-support-interface-is-all-you-need/

Edit: it was not ignored, quite the contrary - it's a common practice nowadays.

-

5 hours ago, gr5 said:

Or you can disable infill for this area of the print maybe. Hmm. I guess you'd be disabling skin. So you can disable top or bottom layers for this section of the print potentially.

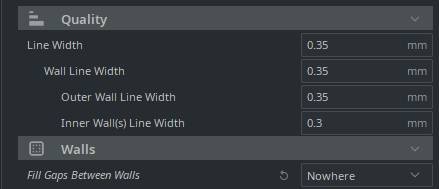

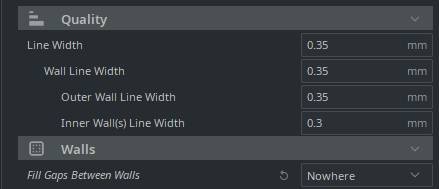

The setting is called "Fill Gaps Between Walls". That's the "small [yellow] strip" in preview. Set it to "Nowhere".

5 hours ago, gr5 said:maybe close enough if you play with the line width.

Yes, choose proper values for "Outer Wall Line Width" and "Inner Wall(s) Line Width". The goal is an even number of lines without gap. That's all.

-

2

2

-

-

On 5/9/2021 at 7:46 PM, Haeder said:

Ich meine das die Leveltemperatur = die Drucktemperstur ist --> verifiziere dies aber nochmal und melde mich.

Deswegen auch die ursprüngliche Frage, ob jemand weiß wo auf dem auf dem US5 eine Variabel Übergabe stattfindet.

Ich vermute stark, der Drucker entnimmt dem gcode-Header nur die Material-ID (EXTRUDER_TRAIN.0.MATERIAL.GUID) und verwendet dann die Temperatur, die in seiner eigenen (Material-) Konfiguration hinterlegt ist.

Die Drucker-Konfiguration sollte sich automatisch mit den Material-Profilen in Cura synchronisieren, wenn der Drucker in Cura verbunden ist - und wenn ich das Prinzip richtig verstanden habe...

(das betrifft nur die Material-Profile - nicht die Druck-Profile)

Vielleicht ist das eine Möglichkeit, die Temperatur anzupassen.

Die Material-Einstellungen im Drucker kann man sich zur Kontrolle auch mit der REST-API herunterladen.

-

It is (perhaps) still possible to set the pin state manually with gcode M42 - if you figure out the pin number that refers to "FAN2_PIN"

https://marlinfw.org/docs/gcode/M042.html

-

1

1

-

-

It does not work because the model has no wall thickness at all. It's a non-manifold geometry and therefor cannot exist in the so-called "real world". 🙂

I don't know the software you use, but you should read about how to create manifold geometry for 3D-printing.

For example:

https://www.sculpteo.com/en/3d-learning-hub/create-3d-file/fix-non-manifold-geometry/

-

3

3

-

-

14 hours ago, ceab said:

I recently upgraded to a new router and am struggling to get my S5 to connect to the new network.

Because you don't mention it and the router is new:

Be aware that the printer can't connect to a wifi that works in the 5GHz band. You need to setup a wifi channel at 2.4GHz for Ultimaker printers.

In addition:

Printer is obviously a bit picky about the name of the wifi (SSID):

-

That said...

I'm not sure, but you can perhaps achieve something with the "expansion" settings. Perhaps in combination with the scale tool... dunno.

It's no replacement for a proper CAD application, but it's at least ...something 🤷♂️

-

5 hours ago, terrypin said:

Essentially that the walls are fixed so prevent any thickening of the walls, yes?

Yes - as i said - the geometry of the part is defined by the loaded model. Cura does not change this.

What you probably call a "box with walls" can also be seen as "cuboid with a cavity"...

The term "wall" has a different meaning in Cura.

Think of a "wall" in Cura as the shell around the given model.

Or translate "wall thickness" to "horizontal shell thickness" if you want.

It's easier to see for models without cavities but the principle stays the same:

-

2 hours ago, laurabrightmoon7 said:

What am I missing??!?!

a brief instruction:

- check the normals (first learn about the SketchUp concept of "front" and "back" surfaces)

- in SketchUp "dark gray" indicates the back side of a face

- reverse all faces that are not displayed in white (context-click and select "Reverse Faces")

Letzter Punkt im Layer

in Deutsch

Posted

Da kommen mehrere Einstellungen in Frage. Ich würde zunächst mal schauen, ob unter "Experimental" alle Optionen für "Coasting" und "Wipe" ausgeschaltet sind. Das müsste der Standard sein, aber sicher ist sicher.

Die Z-Seam Position hast Du wahrscheinlich fest vorgegeben?

Deiner Beschreibung nach könnte es etwas zu tun haben mit der "Outer wall wipe distance"

https://support.ultimaker.com/hc/en-us/articles/360012512340-Wall-settings