-

Posts

257 -

Joined

-

Last visited

Content Type

Forums

Events

3D Prints

Posts posted by personal-drones

-

-

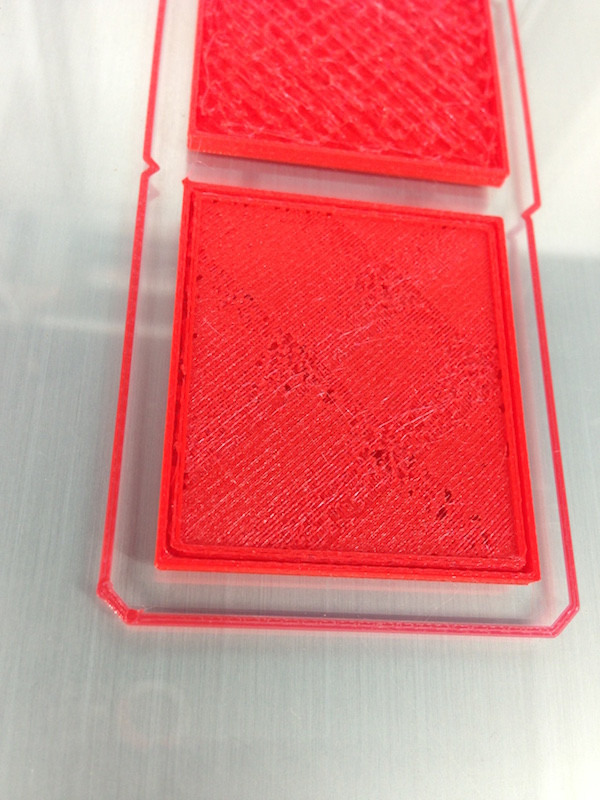

happy to report that after the 3x atomic cleaning this is what i got:

Looking pretty much perfect again. So definitely there were some carbonized debris that were preventing the filament to flow freely.

The quality I get when the UM works properly is quite amazing. Very happy with this machine so far. The forums are an amazing resource.

-

As an update to this. While changing filaments, I was under the impression that in the extrusion phase, the finale phase, the filament did not came out as nicely as the first times. So I went for the atomic method.

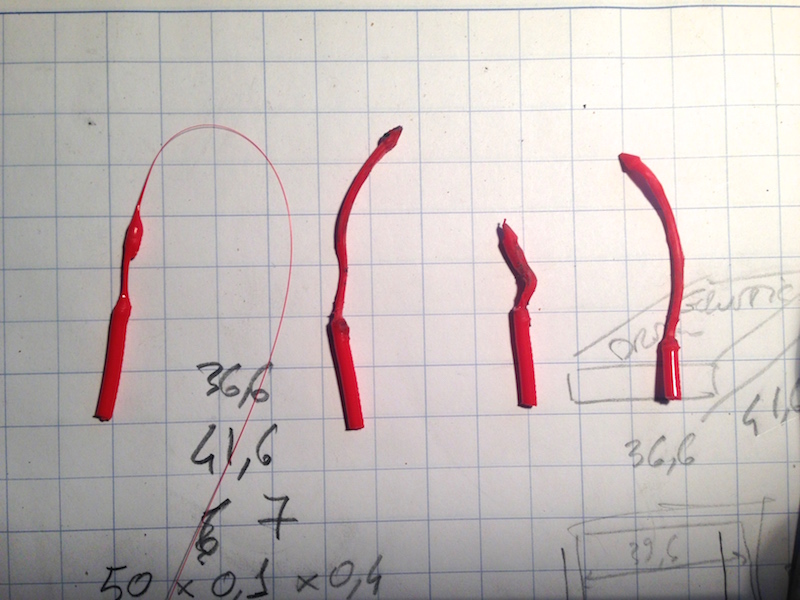

the first on the left is as the filament came out. Then 3 rounds of atomic cleaning.

Indeed in the first round you can see that there are some black residues. Less on the second and gone on the third.

Can these residues justify the problem I was experiencing?

Now I am doing another test print and it looks much better, at 210 degrees this time. Will keep you posted.

I have a question: in the atomic method it suggests to move the head to the front. And that maybe switching the machine off and back on would be required. I was unable to move the head, even after a power cycle. No big issue, the atomic went smoothly. Still curious to know how to "release" the motors so that I can move the hotend on the axis freely.

Thanks for this great forum, so informative.

-

Hello, I have an Ultimaker 2 from a couple of weeks and starting to experience very significant underxtrusion problems than currently undermine my capability of printing anything.

Still have to contact support by e-mail about this, I am hoping that I can some help right here.

Some details:

Got the machine, calibrated the plate. Very pleased about how easy it was to do that with the guided procedure and manual. Also the filament loading procedure went flawlessly. Changing filaments on this machine is so easy.

The mandatory ultimaker mascotte from the SD card printed quite all right, although I was not impressed with the quality of the overhangs. I am aware that some tuning might be required for this model, so I was pleased with the result.

Then I decided to print a pens holder. Since it was not critical to get a top quality for this item, I went straight for the "quick" profile in cura.

The result was entirely disappointing, very far from any acceptable standard:

Very bad underextrusion, the layers did not fuse and the object is entirely delaminated.

So I started browsing the forums and learned about underextrusion. I have carefully read several articles, including the great Illuminati article on underextrusion, and understood that maybe I was asking too much from the machine.

Mind that all I was doing was to use one of the official profiles for the UM2 in cura, I did not touch any expert setting.

So I ditched the quick profile, which appears to be totally unusable in my hands, I started using the medium profile and raising the temperature, with the idea that this would mitigate the uderextrusion problem (which indeed it does, in part).

I also moved my spool on the floor, on a spool holder, to feed the filament more straight into the feeder hole, as I read that this could also contribute some friction.

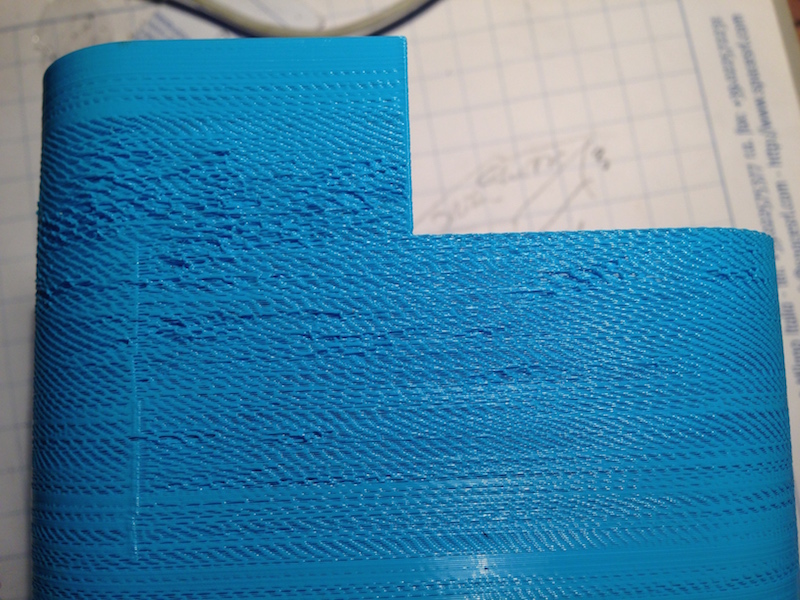

I was able to print a number of pieces I am very happy with, here is an example:

The pens holder and the DNA molecules you see came out nicely.

So all went well for 3-4 days, until yesterday, where I again started to get very severe underextrusion. Except that this time I was with medium profile, at 226 degrees.

So my room for using the temperature to mitigate the underextrusion appears to be gone.

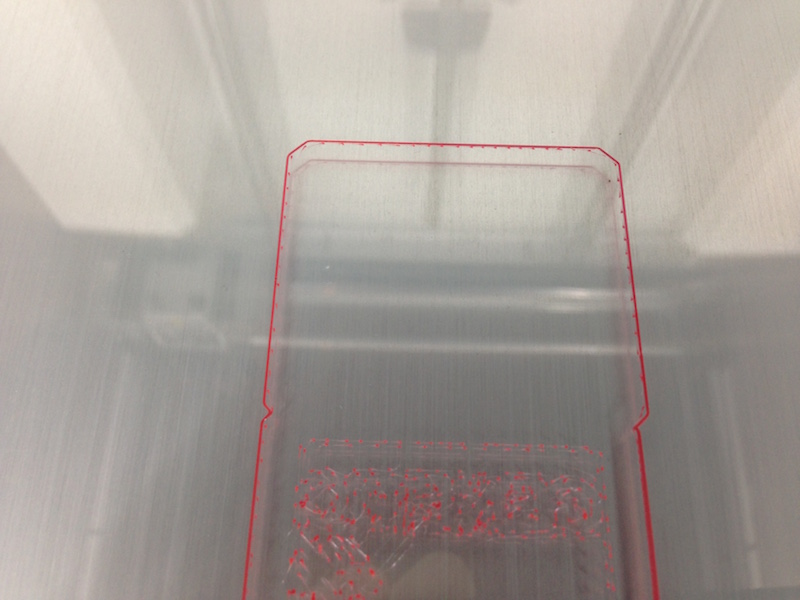

Check out this attempt at printing a box.

First foto is at 210 degrees:

See how severe the problem is.

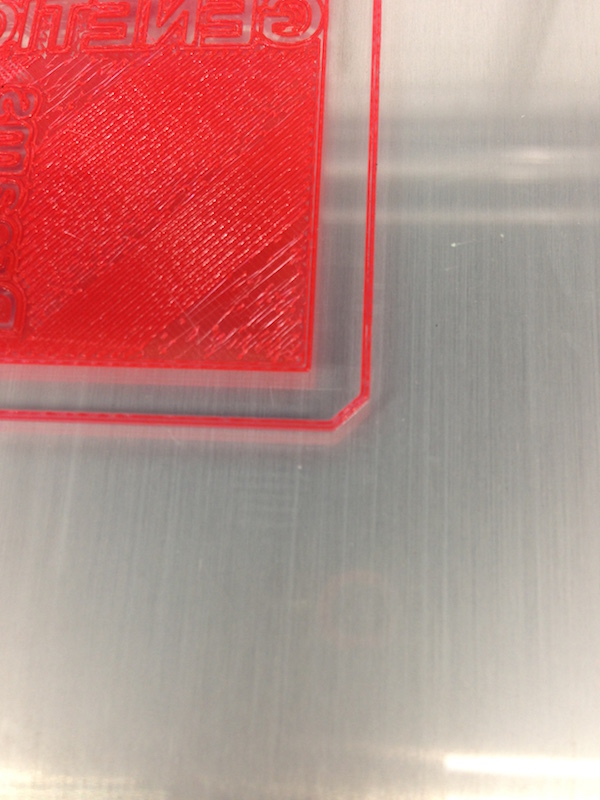

At 230 degrees it was much better, but I still had to stop the print because the result was entirely unacceptable.

On the picture below, lower part, the surface is "finished", this is the final result. At medium quality settings, 230 degrees.

I get the same with 3 different filament brands: ultimaker, colorfabb, formfutura.

I am stuck, after just two weeks of use, with an extremely expensive machine that I selected because I thought it would not give problems, at least for a while.

I would really use some help. Despite all this, I love the machine and would like to see it working at his best, I am confident it can perform very well, and something is wrong here.

As an additional information, 230 is the max temperature the machine has ever seen. Exclusively used PLA from the beginning.

Thanks you for reading up to here and for providing some assistance on the issue.

PD

-

Ciao Sam ho ordinato da voi alcuni filamenti Colorfabb. Oltre al servizio efficientissimo e all'ottima comunicazione, posso dire che i filamenti sono eccellenti. Varie ore di stampa, nessun problema. Packaging professionale, ottime le bobine. Quindi sicuramente ci saranno altri ordini. Saluti!

Stuck Noob

in UltiMaker 3D printers

Posted

In cura, was the object centered? The reason I am asking is that the "messy part" seems to be at the correct location, while the first part seems to possibly have moved from the center. At the end of the print was the first part solidly attached to the plate, or was it just located as in the photo, but not attached to the plate?

In short, as Didier Klein was pointing out, adhesion problems could have done so that the first part moved from his original location (the center of the plate) and the print just went on, hence the "mess".