-

Posts

66 -

Joined

-

Last visited

Content Type

Forums

Events

3D Prints

Posts posted by 3doftom

-

-

Any new news on this from anyone?

-

What are some tools that could be integrated that would facilitate collaboration.

Such as Streaming video meetings with an archive for later access by contributors who come onto the project later in the development timeline.

A file library that folks can check their files in and out of so there isn't any overlap, and so they can request directly in the library view for other contributors to review their work.

Maybe an up voting system for selecting community projects and ideas that have the most excitement or immediate application.

Designating ( giving badges to) members of a project to make them feel like they have more ownership of the roles they are operating in, e.g. Project owner, Lead designer, etc.

A dependency timeline chart thing that would help the community quickly see what is needed next on each specific project in order to move forward.

Maybe sending out weekly updates and notifications of skills that are needed on each project based on the skills and interests that each user has already added to their profile?

A donation system once the product has been developed to give some monetary incentive to the people who contributed to its development.

Sorry if this stuff has already been discussed. I read over this thread a while back and don't remember everything that was in it

-

1

1

-

-

Or one could use any tool and provide the source files in STEP or IGS. Then any other decent tool could import it.

I think this is a better approach. Let contributors use whatever tool they are most proficient in. and just make sure to standardize the file formats that we share with one another. Removing as many hurdles for people to be able to contribute as easily as possible.

-

What are the other options currently for monitoring and controlling your printer remotely? Is there something more user friendly and feature rich right now?

@cloakfiend I agree, I wouldn't start a print remotely.

I think 3dprinteros is a great solution for schools and others who have been placed in charge of a multitude of printers and want a turnkey solution for managing all of the printers and print requests they have to keep up with.

-

I just got my raspberry pi connected up to my printer and created an account on 3dprinteros. I like the idea of monitoring my prints from online while at work. As of right now, I think the biggest features for me will be using the webcam and being able to pause prints remotely if needed. I've only had enough time to turn it on and look at my dashboard on 3dprinteros, have not printed anything yet. I have the free user account.

First impression is that the frame rate is really low for the camera, but I think this is because they are taking a series of pictures, and not video. Not ideal, but I can see it serving its purpose. Also hooked an additional webcam to the pi and that secondary stream did not seem to work. Maybe these features are better in the subscription version.

The interface looks friendly, but slightly confusing so far.... but I've only spent like 15 minutes total looking at it, and most of that was playing with the camera.

I'll share my thoughts as I test it out more.

Anyone else have experience using this service?

-

lol.... I love how so many people jumped in to provide the link!

Thanks guys!

-

Or something else wrong with the extruder - maybe you should print the IrobertI feeder? It's a great feeder and one of it's features is you shouldn't have to buy and screws or hardware more than you already have in the feeder.

Link?

-

Have you checked to see if the 3rd fan is working? (One at the back of print head)

On new machines it should come on above 40 degree, old machines come on straight away.

If this isn't working it can cause similar issues.

Yes, the fan turns on once the print head begins warming up.

-

Thanks George!

I have another question.

When pulling the filament back and forth by hand from the back of the feeder, through the bowden tube (while the feeder motor is disengaged and not running), should there be any moments where there is greater resistance than at other times while pulling it back and forth? moments where it is really difficult to pull it or push it through?

I took the bowden tube off, inspected it and tried pushing some filament through to test if it had any resistance before doing what I mentioned above, and it felt and looked ok.

-

ok. thanks guys

-

Can I lube the bowden tube with olive oil, or is there something better than that to use than that? I don't want to start cooking something on my printer...

-

1

1

-

-

Based on the video, it seems like my print head is heating up properly.

I detached and checked the bowden tube for any obstruction. Found that the filament was broken in a couple places inside of the tube. There was quite a bit of resistance at the feeder end of the tube when manually running filament though by hand. I straightened that out some and it seemed to smooth things out. I swapped out the filament with another brand.

I increased the flow rate, decreased the print speed, increased the temp... It still slips. lol

Maybe I should get a new bowden tube and try that?

-

Thanks George! I'll try that when I get home.

-

I replaced the PTFE coupler. The interior of the old one did look to be a hair larger in diameter than the new one. And I shortened the gap between the PTFE coupler and the steel coupler. I don't think I went too far, cause there is a spacer between the nozzle block and the fan shroud keeping them from touching each other.

But, unfortunately the feeder is still slipping and I'm still getting under extrusion.

Is there a way to test if the temp sensor is faulty before replacing it?

-

My flight leaves tomorrow night around 10:00pm.

I'll try your suggestion on the coupler when I get back from the show.

I really appreciate the detailed response!

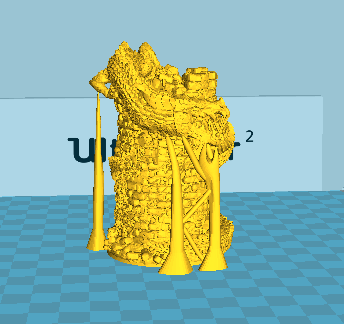

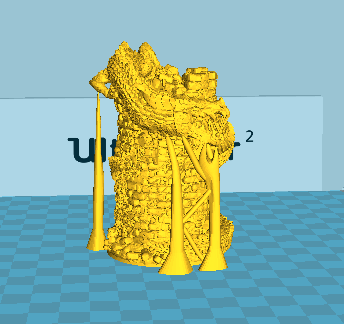

Here is the object that I wanted to try and print on the Ultimaker so that I could bring it to the show. It printed pretty well before the extrusion problems started, but there was too much overhang under the jaw for the supports to take care of it. I've since manually added some supports in the file to help out the auto generated ones:

Manually added support in modo, shown in Cura:

Manually added support in modo, shown in Cura:

It would be cool to print it larger than the one in the picture in the future.

Thanks for your feedback! I'm looking forward to taking it apart

-

Check your advance tab, under speed, and see if Infill is at 85mm/s. The advance speed overrides the basic speed if you have them set to non-0. (if you're using older cura)

If your basic speed is 30, and your infill is 85, it will cause all kinds of issues since 220 is too cool for 85mm/s and too hot for 30.

Try setting everything to 40mm/s on your next go in the advance tab except for initial layer speed.

Thanks! I'll try that next and let you know how it goes.

Failed again. It stops extruding about at the same place as it did last time, about two hours into the print. The feeder is also not able to push any more filament through, so the bolt is slipping...

Here is what the filament looks like after heating up the head right after the print and just backing it out. It sounded like it was catching a little when I was backing it out.

also, is it ok that the hot end isolator is discolored on the underside?

-

Check your advance tab, under speed, and see if Infill is at 85mm/s. The advance speed overrides the basic speed if you have them set to non-0. (if you're using older cura)

If your basic speed is 30, and your infill is 85, it will cause all kinds of issues since 220 is too cool for 85mm/s and too hot for 30.

Try setting everything to 40mm/s on your next go in the advance tab except for initial layer speed.

Thanks! I'll try that next and let you know how it goes.

-

Is it possible that the temperature sensor isn't reading properly?

Print head getting too cool as it moves up the print?

-

1

1

-

-

I've been working through trying to figure out why my printer is inconsistently extruding.

Looks like it under extrudes on the second layer and on the infill. the outer shell looks ok. I've just aborted the ones that are disks, but the prints in the pictures below that have gotten a little ways up end up failing because it completely stopped extruding. Using the original silver PLA spool that was provided with the Ultimaker.

- have done several atomic pulls, they all look clean.

- thought it might be clogging because the bed is too close, re leveled the bed a couple times.

- started printing at a slightly higher temp (220) and that seems to give a little better results for a little while.

- reduced the print speed to 30mm/s on the basic tab.

- I assume that the PTFE Coupler is still ok (looks ok from visual inspection without taking anything apart) because the printer is so new.

- tried setting the filament on the floor to decrease resistance.

- tightened, printed, then un-tightened the tension spring on the feeder. Both failed.

I think this started happening after I tried to print something on the default Ultra setting. Failed on both high and normal settings after that.

I did notice that around the time this last print failed, the filament was slightly losing tension at the feeder. (the white tab is all the way at the top) It wasn't making that "tock" sound, it just sounded like it was kind of slipping I think.

The filament broke inside the bowden tube on one occasion, then looked like it broke at the knurled bolt because of grinding down another time.

What do y'all think? Thanks for reading through my post

-

This guys uses a Stratasys Mojo for his prints: http://www.hauke-scheer.de/index.html

His results look pretty good.

-

There is no joint that is universally useful. There are ball joints that are pretty good for articulated figures, but that might have too many degrees of freedom. Hinges with dimples in them that allow for click-positioning. Yada yada.

Thanks danilius. I'm not necessarily looking for a universal joint. Just looking to learn and share ways that others have found success when designing such models. Best practices when going about this type of design challenge.

Thanks for commenting, please feel free to share more

-

I would recommend to get in touch with Aaron, he made Ronin which is fully articulated! (also shown on our homepage)

I can introduce you if you want

Thanks Sander! That would be awesome. I appreciate it. The Ronin model is amazing!

You guys have a huge version of it you take to events, don't you?

-

Hey everyone,

Something that I would like to do down the road is make some articulating toys. I wanted to know what shapes and configurations for joints has worked the best for you, using the Ultimaker/ FDM printing. Best practices when it comes to orientations on the build bed and other considerations.

Thank you for the insight, I'm sure everyone would love to hear about the success and failure stories around these types of designs

-

1

1

-

-

How do I mark this question as resolved?

If I try to select a "best answer" then I just get re-directed to a 403 forbidden page.

I'm guessing that issue has already been addressed on the forums and someone is already working on a solution.

Innovation platform

in UltiMaker.com

Posted

Might be able to draw some ideas from this platform?

https://artella.com/#/home