Ca3PO4

-

Posts

34 -

Joined

-

Last visited

Content Type

Forums

Events

3D Prints

Posts posted by Ca3PO4

-

-

Can anyone help me out , if someone has theis can you pass it on I cant find it .

-

Hi , iv got an Ultimaker original with self built heated bed upgrade, got glass ontop of the heated bed and I would like to add an auto bed level sensor the question is what kind of sensor to get , theres a shop in my town they got an optical and induction , which one is better? Does adding such a sensor guarantee that the bed will always remain level ?

The second question is how do i connect the wiring to my ultimaker original main board, I mean would i just replace the z endtop connection with the new sensor or do I have to connect it else where ? are there any printable mounts for the sensor if so please please share

Thanks for your time. Looking foreward to a reply.

-

Ok I have solved the problem . It was the print head screws too tight. After loosening those screws a little it works fine now .

-

2

2

-

-

Ok iv tried printing with the 2.8mm set under the filament diameter, there was significant improvment however I have also noticed something else, if i dont prime the nozzle before printing heavily there is almost no filament coming out from the nozzle. And when I look at the speed at which the feeder sprocket is turning its hardly moving at all. SO without priming manually before the print no Filament actually comes out the nozzle ! I checked the spring at back its 11mm , i even installed a new thermocouple. Still get this issue I am now beggining to think maybee its my firmware I flashed I have a self build heated bed kit so i downloaded a firmware that is not the original.can you measure your filament with a caliper?

the package says: 3.00 mm max., and mine measures 2.8 mm, so you are under extruding if you fill in 3.00 mm.

-

can you measure your filament with a caliper?

the package says: 3.00 mm max., and mine measures 2.8 mm, so you are under extruding if you fill in 3.00 mm.

Aha I think you are right I just measured the filament and yes it is indeed 2.8 mm wow im shocked. Ok im going to see how it works with the 2.8 mm in setting and let you know. Thanks for the input .

-

I get the same thing happending when printing this in the New CURA. Bottom to middle half prints amazing but the trouble is with the top . Stops extruding at the stop ?

-

Hi thanks for replying sure ya here are some photos of the prints. Actually they come out nice but only for the bottom, the top as you can see has problems the printer stops extruding when printing the top. How can I fix this issue ?

http://www.mediafire.com/view/qib88dbhhy9b98l/20161219_171908.jpg

http://www.mediafire.com/view/31cqq5s2y3loxmq/DSCF1730.JPG

http://www.mediafire.com/view/fdjdvrassfc7vc4/DSCF1729.JPG

http://www.mediafire.com/view/ezdge7gdrd8hdyp/DSCF1728.JPG

http://www.mediafire.com/view/dcrnf3wtb922vzm/20161219_171635.jpg

http://www.mediafire.com/view/6om4pwcljpwvqak/20161219_171542.jpg

-

Hello I installed a 0.2mm nozzle and am trying to print a model which came out real nice with the stock 0.4mm nozzle however I thought that the 0.2mm would improve dimensional accuracy. Unfortunatly im having some trouble with the print I just cant seem to get good prints I mean I starts off alright but towards the end of the print I get problems it looks like under extrusion . Included is the model im printing with my settings in the gcode. Hopefully someone can recommend a solution to get the sharpest possible print. Thanks . Oh ya im printing 3.0mm Mouldlay wax.

Link to download model :

http://www.mediafire.com/file/ftlut8rrxhhxwbr/UMO_PM9+molar+6.gcode

-

I will try it with the aluminium thank for the advice.First print the fan duct on something that can at least resist 80C, ngen, xt, pla-tec, etc.

Second, try to apply Aluminium tape that can resist 140C, there are lots of tapes that resist that level and there are tapes that can go up to much more, but in my experience with 140C alutape my fan caps haven't bend or deform much.

Other fast solution, but won't last more than a few months and you will need to reapply it's to use kapton tape. The inside covered by it might deform a little, but it shouldn't bend as much.

The biggest problem you will get with pla, it's that all the time the fans are off the pla will get heat from everywhere and it starts to deform quite fast at 60C + the weight of the fan won't help. Also the heat from the umo block it's around 150C at 3mm after a while, so that fan cap will have troubles resisting the heat without some aluminium foil to keep the high temps from hitting the printed part.

Carbon filaments (at least formfutura) compresses on itself when exposed to heat, so it works quite nice.

Worse case scenario you can build a cover to block the heat from hitting the fan cap with a soda can, but carefull because they can do nasty cuts while handling or if you don't file the metal after.

-

a) use a different duct design that does not get so close to the print-head,

b) print it with ABS or polycarbonate, which tolerate higher temps than PLA

Hi thanks for the reply , any suggestions for a fan duct which is best for printing small parts ?

-

O yeah i forgot to say the duct is printed out of PLA and i mainly print at low temps, 200-210C

-

Hi Im using the ultimaker original with a custom printed fan duct and its so annoying im on my 3rd one now because the thing keeps warping then eventually touches the heater block and melts, how can i fix this any suggestions please ?.

I downloaded the fan duct from here its a pretty popular choice http://www.thingiverse.com/thing:17768 .

-

I just cleaned the nozzle , put it in a special burn out oven then blased it with a compressor. It was definatly clogged. Gonna try to print now with new colourfabb PLA i bought. Dont know if I should drop the flow rate from 100% to 70% to compensat efor the smaller 0.2mm nozzle ?

-

Sure i can do that , well i have printed 0.05mm and even 0.02 layer height and the prints come out great with the stock 0.4mm nozzle . Just trying to use the new 0.2mm. I was able to get a print done halfway through then i gues my retraction was too high and the platic was getting stuck in the white PTFE coupling , i cleared that jam and put back together but now i get no more plastic coming out of the nozzle end even though it is full of plastic inside so i guess it must be clogged. There could be some residue from other filaments i tried to print with before such as the mouldlay wax and or PLA .You layers are too small. I recommend you get your nozzle from a trustable resource because china could have bad manufacturing of the nozzles on ebay. Can you post some videos/pictures of what happens with the 0.2 mm nozzle?

-

Hi , nope no filament in the nozzle tip , however when i unscrewed it from the block i could see the nozzle is full. I print at 0.05 layer height. Like i said I get great prints with the stock 0.4m just wanted to upgrade to the 0.2 for finer output. I ordered a cheap 0.2mm nozzle for the ultimaker off of ebay.Can you see filament in the nozzle tip? Do you have it disassembled? What is your layer height when you print with the 0.2 nozzle?

-

When i print with the 0.4 ultimaker nozzle it works fine. But when I try the 0.2mm nozzle it causes problems. Iv just checked the nozzle and it might be clogged the nozzle is full but nothing comes out of the hole .You might also want to measure the PET with a caliper to make sure it is in the range of 2.8-2.9. If is not that might be why you are having issues with it.

-

Hi thanks for the reply ya its the Innofill brand PET on the spool it says 190 - 210C print temp. PET is low temp . I will try to lower the retractions I am also thinking maybe the flow rate needs a reduction since the smaller 0.2mm nozzle but im not sure. I do know that that the clogging is happending at the white coupling maybe halfway through the print job . Starts off nicely tho.9mm retraction will make clogs even with pla. You are moving hot filament to a cold area, that clogs ofc. Retractions of 4.5 should just work, maybe 5.5m

Also PET temperature it's just 210? I thought pet needs much more? I never printed pet

-

Hi , I installed a 0.2mm nozzle on my ultimaker original and am printing with PET 2.85mm filament at 210c, print speed 20mm/sec , layer height 0.05mm, retraction at 60mm/sec distance 9mm . flow rate 100%. Starts print off nicely and then it clogs the with teflon tube and the filament wont pass that no more. I have specified a 0.2mm nozzle in my settings in Cura already

Any suggestion as to what to change in my settings to prevent the clogging ? what is causing this problem . is it too much flow rate , too much retraction possibly?

-

What sort of settings would be recomended when printing with a 0.2mm nozzle with 2.85 filament, i mean i have reduced ther flow to 70%, print speed i do at 40 mm/s anything else to help compensate for the smaller nozzle?

-

Yeah I tried the 1.75 mm filament and as mentioned above it didnt really work , the feeder didnt like it. So im just gonna go with stock 2.85 mm filament but i swapped the nozzle to a 0.2 and im seeing a significant increase in fine detail.

-

Hi , the plastic isnt going in the oral cavity, it getting burned out in an oven then the form gets pressed with a biocompatible ceramic, I know quite alot on biocompatability, I hold a doctorate with the faculty of dentistry I was and am involved in research . I am aware of the DLP and SLA printers, I was considerig them however right now im using the ultimaker and must say at 40 - 50 microns the lines arent visible. Especially if we print it in wax then it can be hit with a quick blast of a torch and any lines if any disapear. There was a doctoral thesis on this performed by a student in the Czech republic , the individual had used a rep rap printer for his experiments and concluded that it is accurate. And I must say I am happy with the results im getting , the crown fits, the lines arent visible at 40 microns in PLA also the tight fit is really good, so i must say this method will work. Temporary caps yes this could work also but im going full ceramic with these. Also I have been playing around a bit and have discovered something interesting alright when I do 3 at a time in cura iv noticed that when I flip one of the 3 crowns I get the problem which I was getting before removed you can see it in my pics , ok here it is before i fplip one crown , you see the blue line at top and the extra red lines below which would cause the dripping of meterial which ruined my print.

http://www.mediafire.com/view/h8z47i911jp1a8u/prob1.jpg

Now take alook at what happends when i flipped just one crown

http://www.mediafire.com/view/khav54ajdzacyoj/prob2.jpg

The blue line dissapears and only one crown has the extra layers overtop of it hmm, iv printed it and this works but why must i have to do this flip one crown to eliminate the blue line at the top ?

-

Hello there thanks for all your help I will also share a link where I initially got started in meshmixer on designing this print before exporting into Cura . I used a 20 micron scanner to scan a dental tooth stump. Then I have to fix up the mesh in meshlab and put into meshmixer and finally Cura for my ultimaker heres the link to my thread on the meshmixer forums http://meshmixer.com/forum/index.php?topic=2714.0

Also the idea here is to seat the printed crown onto a tooth stump which you will see in my post on the meshmixer forum and that can aslo be printed as thats the idea behined it to print the tooth and seat it perfectly onto the stump. So like the support has to be as far from the bottom of the crown or margin since thats the part that gets cemented into the patients mouth. So the support must go on the sides or the top also known as the cusps as to not interfere with the seating on the stump. So its best to print it upside down or sideways but then i get that annoying dripping on the margin dont know whats causing it i called ultimaker they are looking into it, i sent them the file and they said that in the layer view you can see the extra layers at the top which are responsible for it, they said they are still working on figuring it out whats causing it. One lady at igo3d Germany suggested to remove the

G0 F9000 X115.354 Y109.494 Z17.042 command from the Cura generated Gcode , however i cannot locate such a code when Cura generated the gcode from the .stl so im still waiting for help. I will try all of your suggestions such as printing more at a time , I seen the pics from BrayChristopher however unfortunatly that print wont work for this application as the margin of the crown has to remain unaltered and it wont fit onto the stump i scanned because the support made it jagged, please see my link from meshmixer forums you will see the stump there.

I will see how printing more at a time will help . Also in a couple days im getting 1.75mm moulday with a 0.2mm nozzle, gonna try it with that see how it works out.

-

No replies hmm, hmm common im sure there someone knowledgeable out there?

-

Hi , im trying to troubleshoot this annoying dripping i get each time the print is done it ruins the work by driping over my print how can i prevent this from happening.

Here are some pics

and my settings, its an ultimaker original.

http://www.mediafire.com/view/8g4wg4q8pr8b0by/crown..jpg

http://www.mediafire.com/view/vnjtxbm2w5ho4b4/crown....jpg

settings

http://www.mediafire.com/view/9hl076czhbyp2c3/settings.jpg

and link to the file

http://www.mediafire.com/download/j3x38ow8z55nqy6/new.stl

hopefully someone can help me out with this problem with the oozing on the print at the end of the print. Thanks

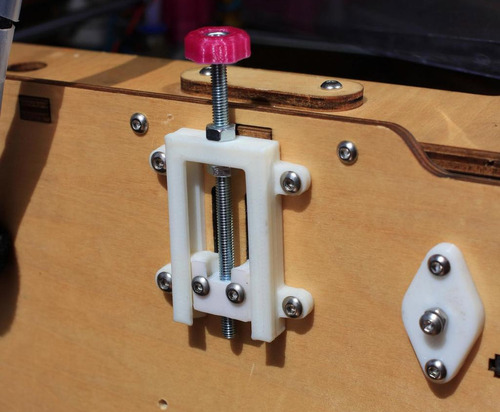

Looking for the popular Ultimaker Original Z adjustment tool print file cant find it online anywhere ?

in Third party products & modifications

Posted

exactly thank you very much.