-

Posts

98 -

Joined

-

Last visited

-

Days Won

1

Content Type

Forums

Events

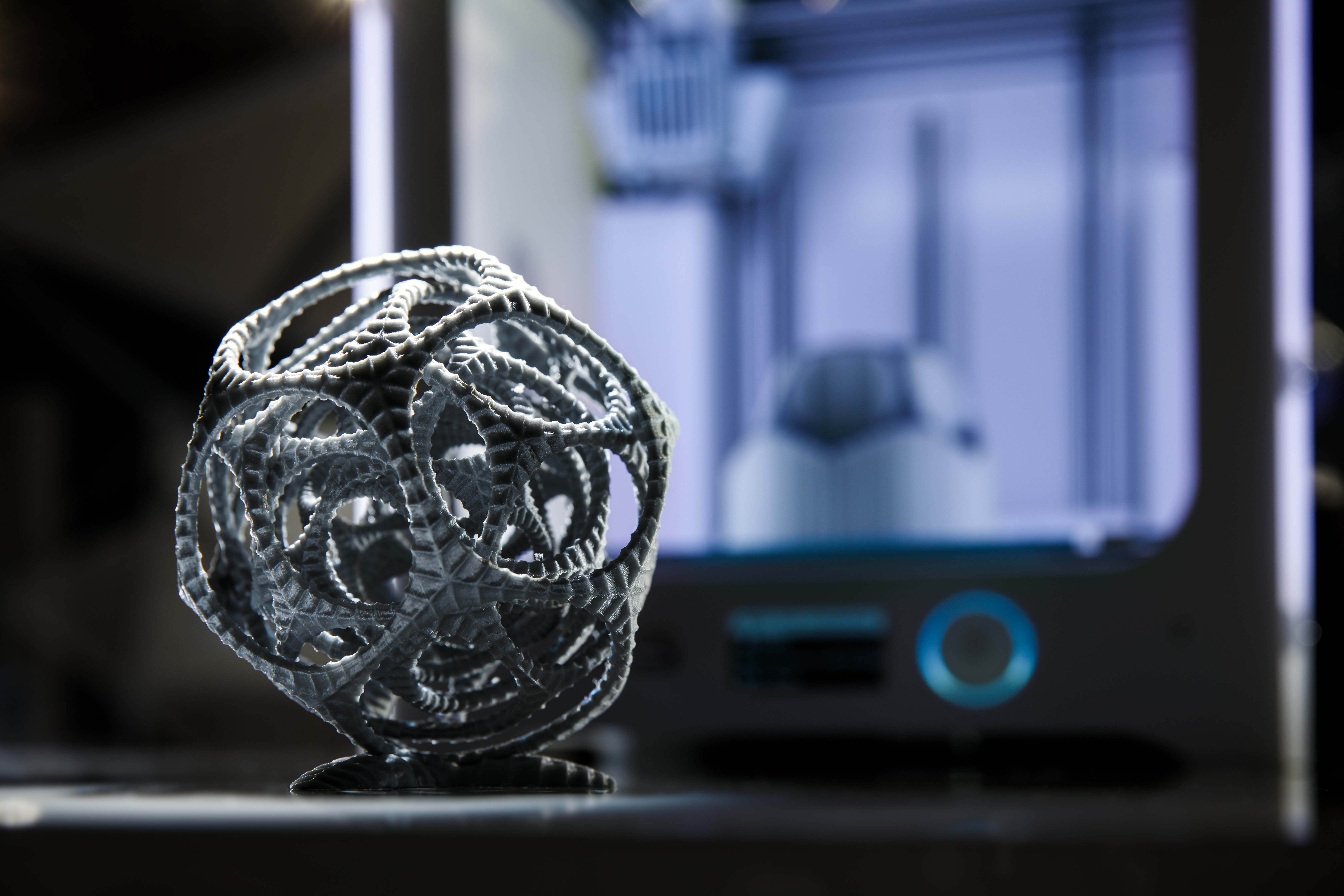

3D Prints

Everything posted by Ghene

-

Thank you!

-

I didn't notice that. ?

-

I noticed that when you have 2 different materials, in my case ABS and PLA, the buildplate temperature needed does not change when you switch. So, I was using all PLA before so the temperature was at 60˚C, when I switch one material to ABS, instead of changing, cura stayed on the initial temperature. I was changing the settings on the printer to no avail. So I checked every single setting on cura and lo and behold, it's the material settings>build plate temperature. Now it's working, I just have to remember switching when I change materials.

-

Sorted! Thank you!

-

Generic setting is NOT at 110C. I created a duplicate and adjusted the settings. Hopefully, this will work out. Why ABS? Because I saw a nice looking pink filament only available in ABS and I want make something with it. If it proves to be more trouble, I'll go back to

-

Any pictures please? I am not having any success with my ABS. Thanks!

-

Sorry to be a pain but my attempts to print with ABS ended up in a pile of blobby spaghetti. I can't seem to raise the printbed is by default at 80C

-

Those are linen and cotton canvas. I have some of those. Actually, I think when I have more time, I will experiment with all the fabrics I have (from hemp to fine silks to natural and synthetic fibres). As some of the fabrics are thick, do you think I should calibrate the build plate with the fabric on or is that a stupid idea? ?

-

I want to try working with thicker fabrics like cotton canvas, linen, suede and some upholstery fabrics. So, slow speed and anchor the fabric properly? Ok.Will try that... after the varse is finished printing. ? Thank you.

-

Thank you! I was hoping to try printing on thicker fabrics. what sort of settings do I need?

-

I saw someone print on fabric using the Ultimaker, anyone know how it's done?

-

? Looks good with flowers but as I can't have them printed as ceramic or porcelain anymore (shapeways stopped printing ceramics), it's just a decorative object in shape of a vase.

-

New make which will be hitting my shops today. Already got a couple of pre-orders ? Im still trying to finish up the male version without it looking ludicrous. ??

-

Wicked! Thank you. Asking for a custom made nozzle will have to wait though. I just shelled out £££ on this new Ultimaker 3 Extended printer and I think I will have civil war at home if all the other stuff are cancelled. ?

-

Thanks! Do you have experience with this brand? What's the print quality like? How does the Cura software communicate with the change? Do you have to create a profile for it?

-

Hey Ultimaker team, Just sending an odd request to you if that's entirely possible. Can we have 1mm to 1.2mm print core nozzles? I know E3D-Online have big nozzle sizes available but as it requires me to build a new printer to accommodate that, I thought to ask you first. It will help me get my investment back quicker (thus be able to afford the next printer upgrade or maybe another printer). Thanks!

-

My pricing method is to calculate how many hours I want my printer to work per day then work out how many years I can realistically pay the cost of the printer back. That amount is then scaled down to how much it cost per minute. Add the wattage consumption per hour or minute. Add the cost of the material etc. To keep the prints affordable, I have to extend the payback period to 5 to 6 years. That's roughly £0.03 per minute I then add your electricity consumption and material to that. I think I can recoup the investment quicker if I make small items I can print quick and in multiples like these we make for our mix media cards, pins and brooches. A bigger nozzle will also help print bigger files faster, thus getting a return on the investment faster. It would be really nice if Ultimaker can develop a print core with 1mm or 1.2mm nozzles

-

How do make multi-colour prints? Is it via print file or is there a trick to make the printer swap extruders?

-

Thank you. Will try the tower option. I do like having the texture I get with positioning it this way. Besides, it's less obvious when printed really fine (at least on my other printers).

-

Hello, I am an UM3E owner for about a week now and I've just encountered a problem which I didn't have with my previous 3D printers.... What do I need to adjust to fix the nose?

-