Have you looked at the settings on your printer? You might have a way to mirror the Y axis.

Have you contacted Convenient 3D? If they say you can use Cura they should know how to configure it.

Hi. Thanks for the response.

I did contact the company, Shenzhen-Hong Cheng Technology, Ltd, and they said "you must mirror the print on the Y-Axis" before printing".

I don't believe that. There must be a way to set it either in the printer on Cura so that it comes out right without having to manually flip it. I can live with the Origin in Cura being different than the Origin on my printer, but I don't want to have to flip every object before I print it (and then forget and have to toss the whole print in the trash)

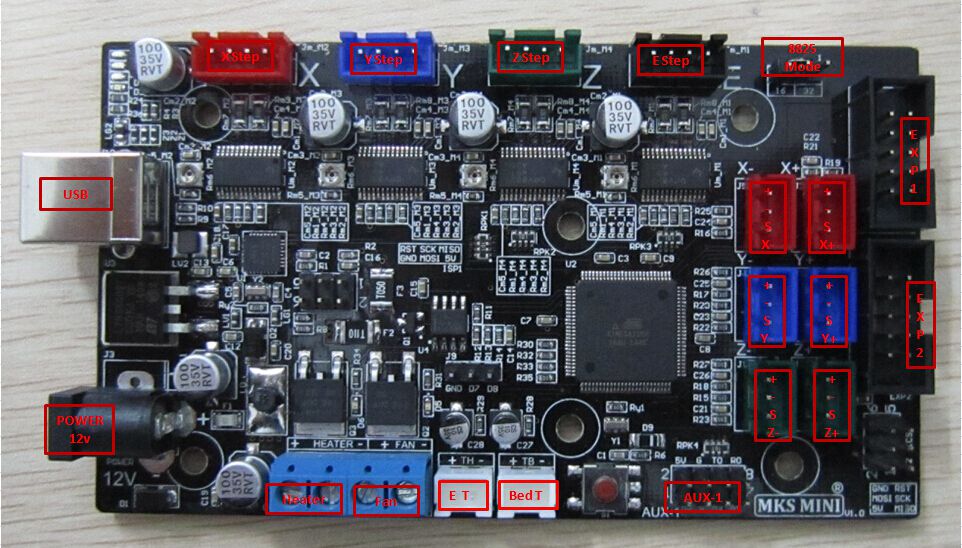

I found the Printer's Main board. Its a MKS MINI. From the looks of Googling it, it seems fairly popular/standard. Maybe there is a firmware setting or jumper setting on it?

I looked through it's menus, but there is nothing on the screen to do that.

Thank you for any help/ideas you can provide!

Wait your saying that you bought a 3D printer that cannot print out of the box? Doesn't it come with a software compatible with the said printer?

It says its compatible with the Pursa Mendel I3.

And it does print (after assembly ![]() - its a kit)

- its a kit)

It just mirrors the objects, so I have to mirror it in Cura so it prints out correctly. Otherwise letters/words are reversed, etc.

It appears to be because the Origin in Cura is in the left-front, but the origin in my printer is in the right-front.

I need to correct the title of this post: It's not mirroring on the Y-Axis, its mirroring on the X-Axis. as the X-Axis is on the opposite side on the printer as it is shown in the Cura software.

The mainboard on my printer, MKS MINI, crapped out the other day and I just got a new one in today. Having to load new firmware forced me to download the Marlin source to configure, compile and upload it to the board. That revealed some settings that allowed me to fix this issue with only a slight hardware change:

1. Plug the X-Axis stop into the +X socket (Max Position) from the original -X socket (Min Position)

2. In Configuration.h, set the INVERT_X_DIR true

3. In Configuration.h, set the X_HOME_DIR 1

Now the print head moves positive from left to right and I didn't need to move the X-Axis stop, just redefine it as the Max instead of the Min.

Now all my printouts are WYSIWYG without having to mirror it in Cura

Awesome you figured it out.

Since its a kit, is it possible that the x-axis motor could be have been installed the other way around in order to mirror?

I looked at that - many times. I was thinking 'Dang, I must have installed the motor on the wrong side of the printer!'

But, no.

I checked the instructions, video and photos many times and they clearly show the X-Axis motor mounted on the left with the zero-stop switch on the right (as you look at the front of the printer).

However, you are right: If I reverse the setup and put the motor on the right side, and the stop on the left, it would match the Cura screen and everything would be shinny.

However, I would have had to swap the left and right panel sides, flipped the bottom board, installed the main board on the left (instead of the right) to match the mounting holes and re-run all the wires. Basically a rebuild. Ugh.

I've thought about telling them they should change their instructions, but they didn't have a clue what I was talking about with the printouts being mirrored...

.thumb.jpeg.0b7a05eafc09add17b8338efde5852e9.jpeg)

Recommended Posts

DaHai8 74

Anybody??

Link to post

Share on other sites