Pin 2 also needs to be at a higher voltage than pin1 so Pin2 needs to go to + power, or pin 1 needs to go to ground and the other pin would go to the HB.

There is a small chance that you didn't damage the part. Small.

By the way, did the HB warm up at all?

.thumb.jpeg.0b7a05eafc09add17b8338efde5852e9.jpeg)

Recommended Posts

joergen 2

most SSR are made to switch a AC load, and will fail/die miserably if you use them for switching a DC load.

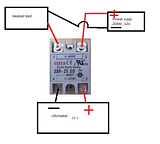

looking at your pictures, it seems to be a (rare) DC SSR. did you mix up the payload with the control side? control is 3/4, while payload (HBP) is 1/2.

Link to post

Share on other sites