Nice, Jason. Please post a link to a recommended power supply also so people can estimate total cost necessary. You kit should include a 4.7K through-hole resistor to be soldered onto the UM Original board.

Do you print directly on the aluminum plate or do you put kapton tape on it? Or blue tape? Or glass on top?

HI gr5, Thanks for reply and suggestion, I will start looking for some 4.7K resistors and put it in the kit.

for power supply, just regular DC Power supply for electronic projects will do, like this one:

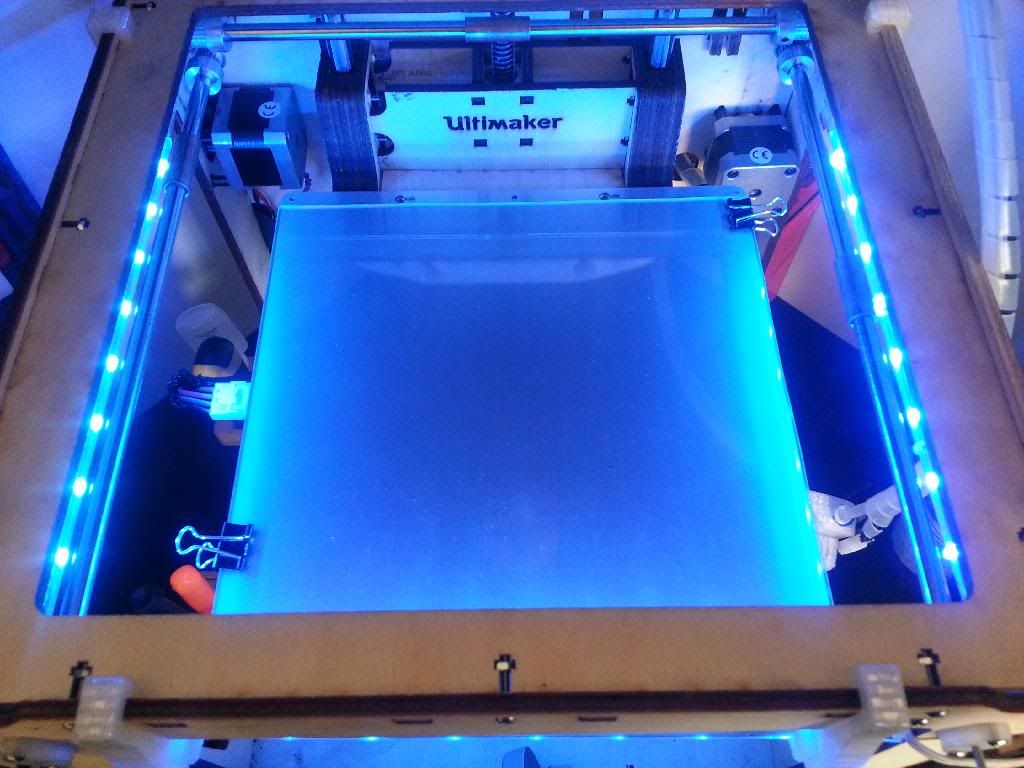

The surface finish of the aluminium plate is actually capable of adhering PLA and ABS at elevated temperature, but I still put kapton tape on it just to prevent scratching. A glass plate should be ok as well, just take a bit more time to heat up. The heat plate is 24x24cm so if you are put on a glass, it should like 24x22cm as there are screws on the edges.

I throw away my masking tape (blue tape) after I got this working as it seems to be useless now.

Jason

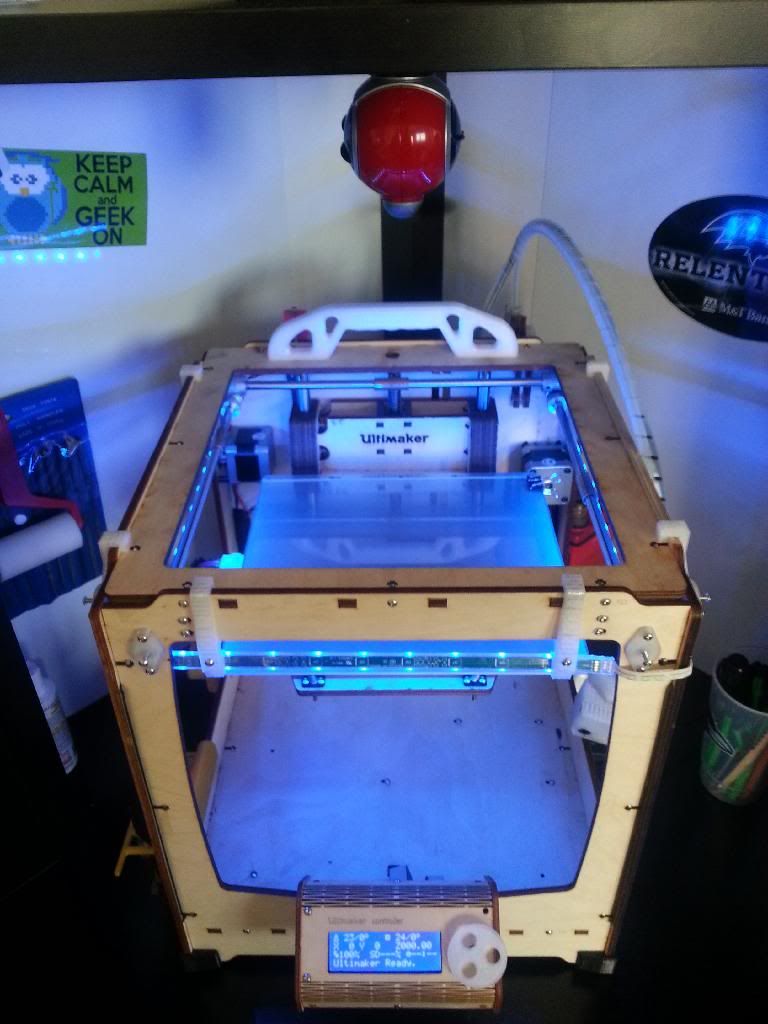

a prototype of the bed with Kapton.

.thumb.jpeg.0b7a05eafc09add17b8338efde5852e9.jpeg)

Recommended Posts

Top Posters In This Topic

24

19

16

12

Popular Days

Jul 10

10

Apr 6

9

May 14

8

Mar 31

8

Top Posters In This Topic

anon4321 24 posts

gr5 19 posts

jonnybischof 16 posts

tommyph1208 12 posts

Popular Days

Jul 10 2014

10 posts

Apr 6 2014

9 posts

May 14 2014

8 posts

Mar 31 2014

8 posts

tommyph1208 55

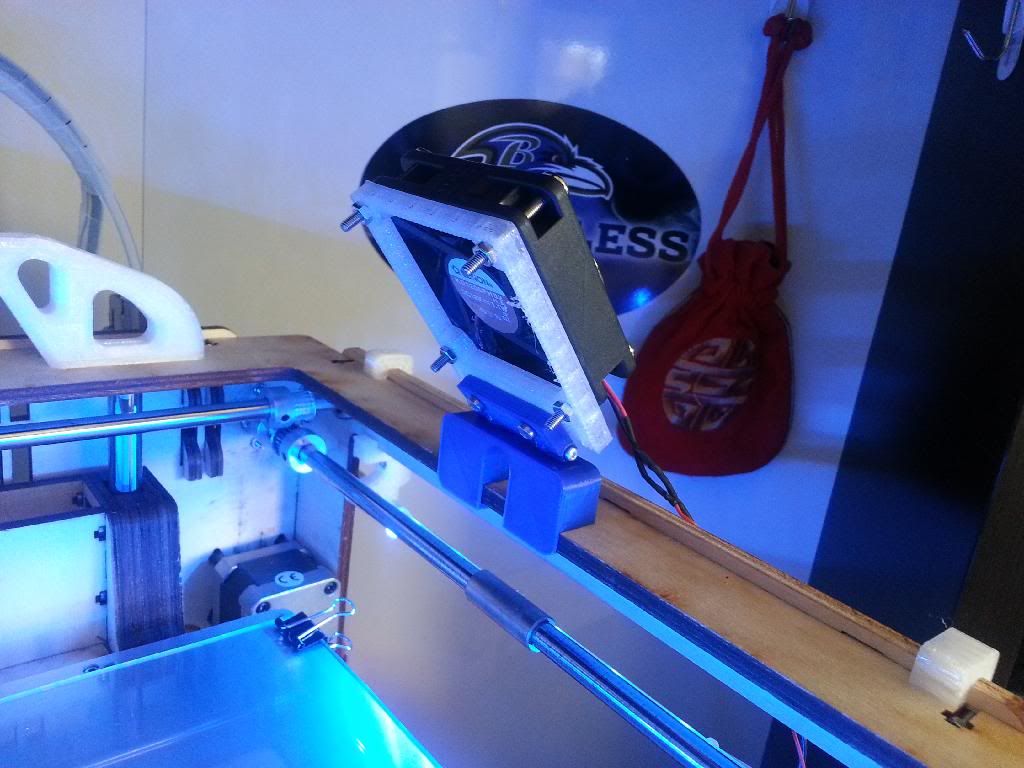

I wanted to use the buck since I want 19 V for the UM board but 24 for the HB

Link to post

Share on other sites