I know its a Firmware bug, so hopefully it will be fixed soon.

A fix is out, it's in the Cura 13.11 release. The default UM2 firmware in Cura 13.11 contains a fix for the 280C bug, a fix for the SD-Read error, and the option to save custom material presets.

Cura 13.11 will also run the fan at a lower speed at the first few layers for the UM2, so the head is cooled less which helps with extrusion.

.thumb.jpeg.0b7a05eafc09add17b8338efde5852e9.jpeg)

Recommended Posts

naz72 0

I decided to replace the ABS with Blue PLA again, & this will always cause an error cause it tries to reach 280c before it retracts the material & triggers the 265c limit sensor & causes an error where you need to restart the UM2.

What you need to do is choose PLA after a restart and than change the customize setting to 260c temp choose okay than goto "Change Material".

I know its a Firmware bug, so hopefully it will be fixed soon.

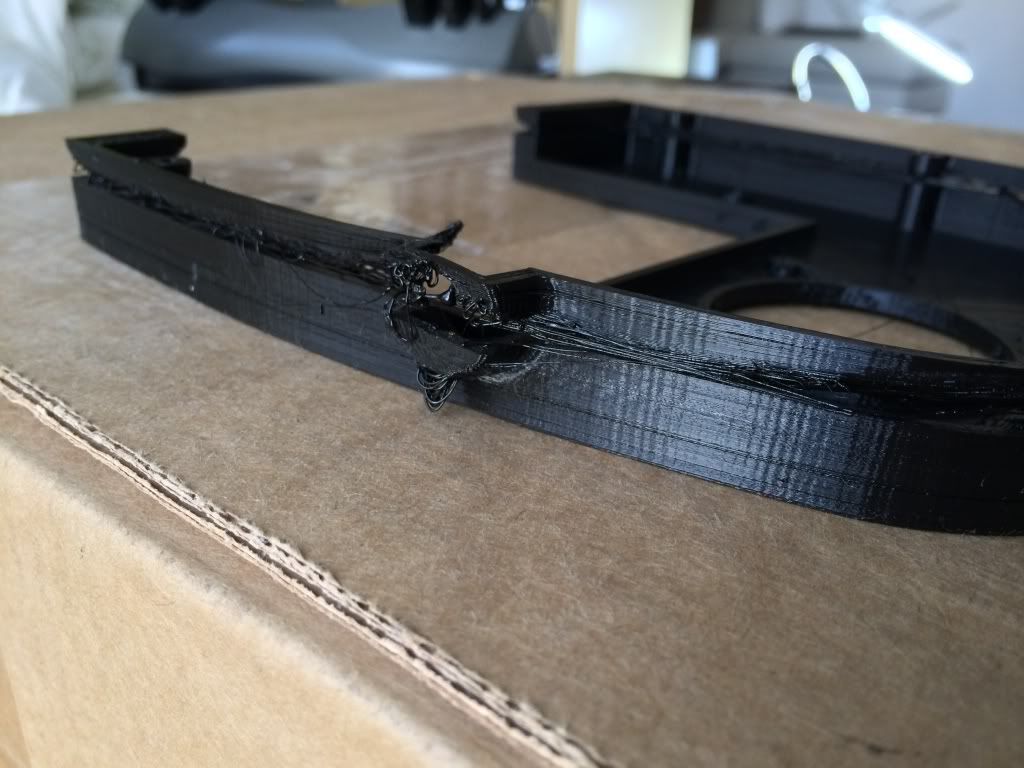

Anyway I wanted to show the slipping even when not printing, this is when you wait for the material change where it says " Wait till material comes out the nozzle", I tried playing with the tension screw but its actually worse which leads me to think that even at lowest settings the tension is too much for the stepper motor or as I mentioned before you need to provide a little more current to the extruder motor. Here is the video.

http://s1206.photobucket.com/user/naser404/media/9E15BE4B-A44F-4484-9DAA-D933836CDEDF-2629-000002A3C48AFC2C_zpsecb1ae5c.mp4.html

Link to post

Share on other sites