Have you updated the firmware - I think the heating failed issue was fixed a long time ago?

Regarding the z-scar, see my blog post:

http://www.extrudable.me/2013/04/02/the-myth-of-z-speed/

Thanks for the tip, I will try to adjust my z-speed. I don't see where I can adjust that though, can you point me in the right direction? I'm running Cura 14.01 on my MacBook. Thanks!

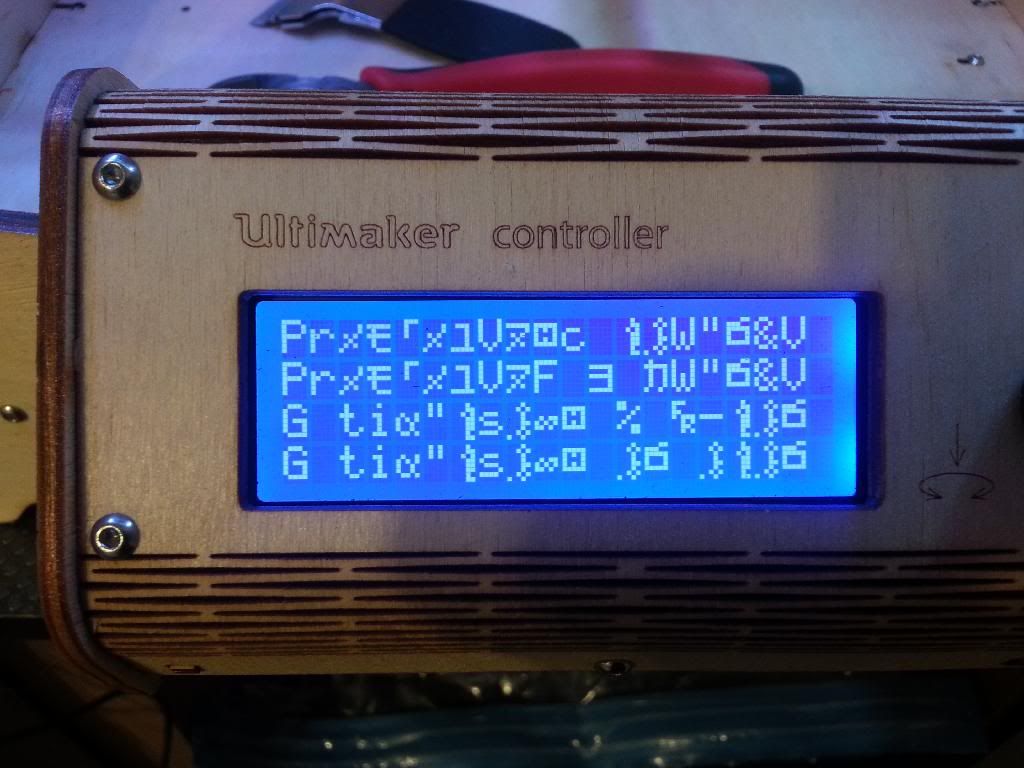

Yes, I updated the firmware. At least I thought I did. Can a check the firmware version on the Ulticontroller? Where can I get the latest firmware download? Thanks again!

.thumb.jpeg.0b7a05eafc09add17b8338efde5852e9.jpeg)

Recommended Posts

illuminarti 18

Have you updated the firmware - I think the heating failed issue was fixed a long time ago?

Regarding the z-scar, see my blog post:

http://www.extrudable.me/2013/04/02/the-myth-of-z-speed/

Link to post

Share on other sites