It looks like ABS is a mistake for the UM2 feeder. It seems to slowly wear, which causes ABS dust to end up in the hotend and clog the hotend. We're working to get the supplier to change the material, but it's not going as fast as we hoped.

A quick workaround is printing the sides in PLA, and use those instead of the ABS sides.Hi David

Hi David !

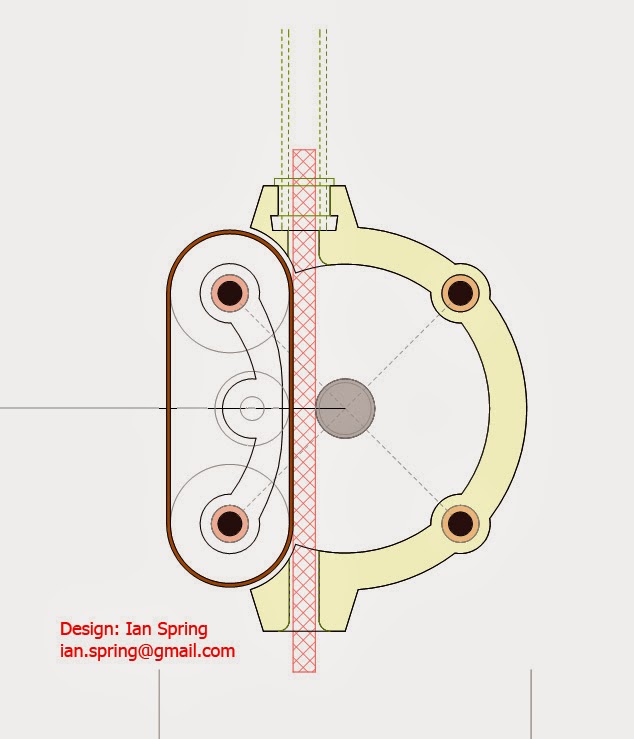

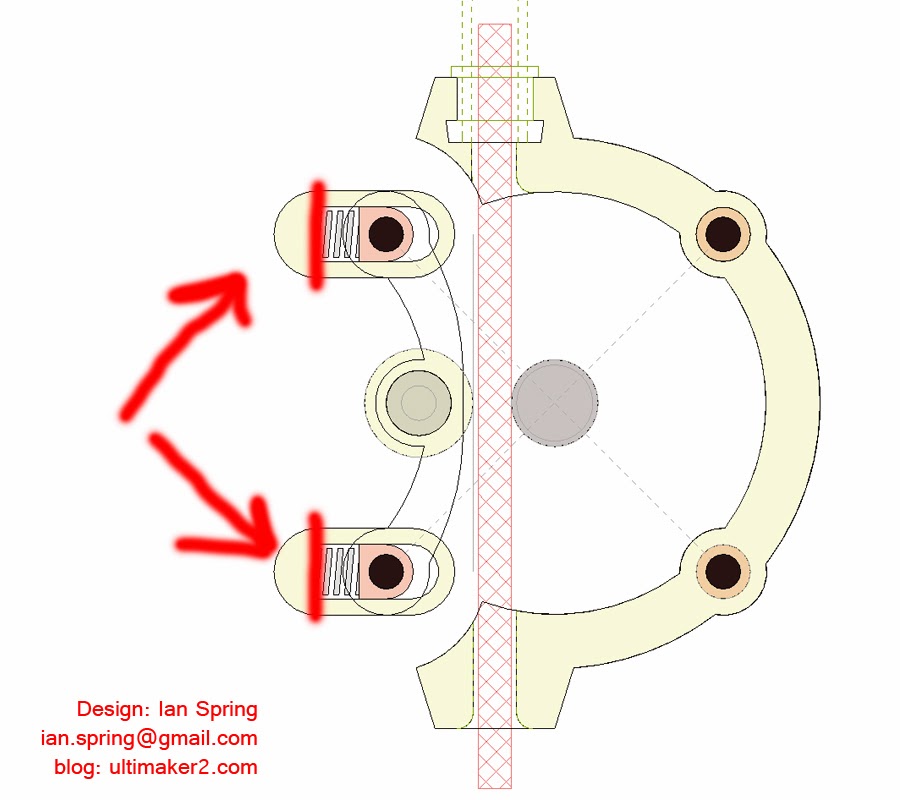

When you guys start producing the feeder housing in a stronger material.. will that be simply the transfer of the existing design to the new material or will it be an updated design for this new stronger material ?

The reason I ask is because there are a few spots inside the housing that simply interfere with the mechanism and break off after a little use.

Have a nice evening ! :-)

Ian :-)

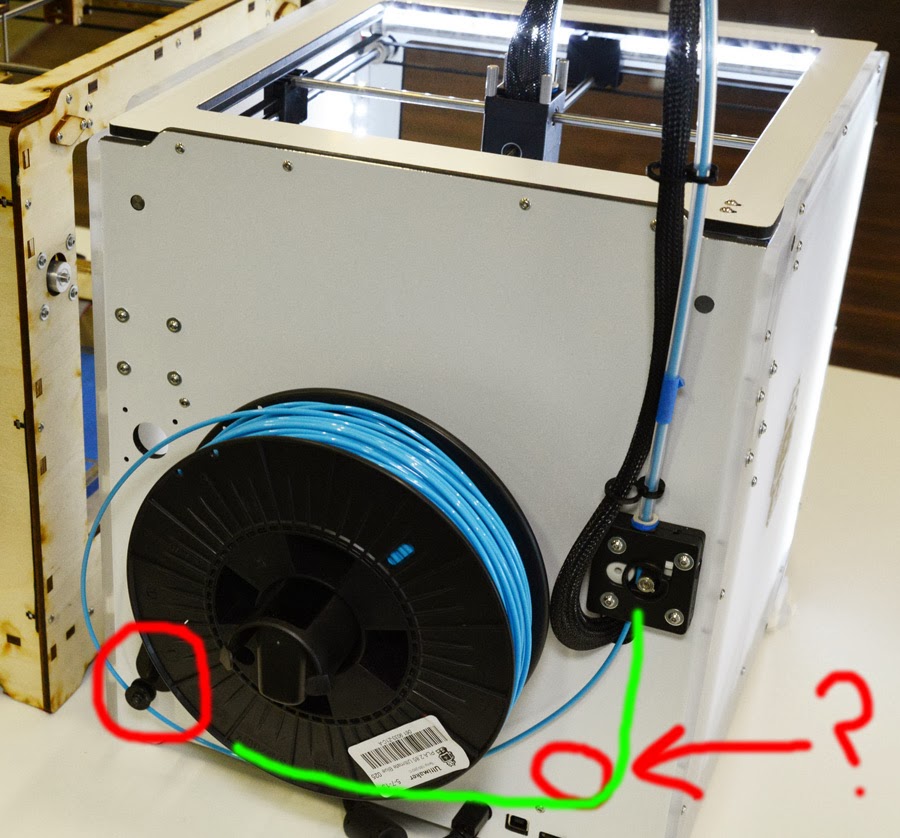

.thumb.jpeg.0b7a05eafc09add17b8338efde5852e9.jpeg)

Recommended Posts

Top Posters In This Topic

120

118

52

37

Popular Days

Feb 10

33

Feb 25

29

Feb 13

26

Mar 27

23

Top Posters In This Topic

ian 120 posts

IRobertI 118 posts

Blizz 52 posts

geeks 37 posts

Popular Days

Feb 10 2014

33 posts

Feb 25 2014

29 posts

Feb 13 2014

26 posts

Mar 27 2014

23 posts

Posted Images

calinb 11

Or maybe print the sides in nylon. I mostly print nylon these days. Also, I just changed one of my company's rapid injection molded parts, produced at Protomold, from ABS/PC to nylon. Nylon is inherently self-lubricating and low wear. Though our mold was designed for ABS/PC and I was initially concerned about the higher shrinkage of injection molded nylon vs. ABS/PC, it's not an issue in our part.

Protomold was very fast too. All I had to do was order more parts in nylon, pay the bill, and scrap the old parts. / :(

/ :(

Link to post

Share on other sites