The community (and also I'm sure Ultimaker) welcomes your modification. I think you might be required to post using the same license as UM posted with but I wouldn't worry about it too much. I recommend choosing the CC attribution with or without the non commercial addition. I'd probably skip that as then Ultimaker can't use it themselves. Please eventually post your design on youmagine.com also. Thingiverse has a click license when you signed up that gives them all rights to do whatever they want with anything you post there. Youmagine does not.

Do you have a heated bed or are you going to use another heater (100 watt lightbulb?), or what?

I found a heated bed to be sufficient for PLA. Are you going to print ABS?

Most of the shrinkage/cooling issues happen from the glass temp to air temp if the model isn't done printing. So for PLA the glass temp is around 60C. For ABS the glass temp is around 100C.

For PLA, heating the air from a typical room temp of 20C to 40C will cut the shrinkage and lifting forces by 2X. 50C even more. Any hotter than 50C is too close to the glass temp and you might have trouble printing.

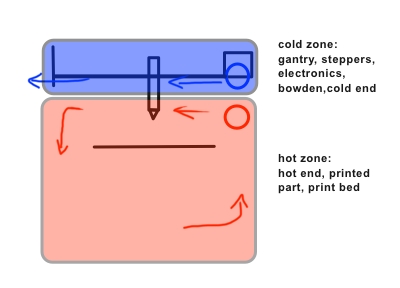

For ABS, raising the air temp from 20C to 40C will only reduce shrinkage/lifting by about 25%. So for ABS you might need to mount your steppers *outside* the frame. Although they get in the way, this is very easy to do and requires no drilling and no additional parts. The motor can be mounted outside the frame and the pulley sticks through the hole to the inside of the machine. The direction needs to be reversed which can be done by rebuilding the Marlin firmware. If you use robot fuzz it is trivial.

.thumb.jpeg.0b7a05eafc09add17b8338efde5852e9.jpeg)

Recommended Posts

shadowfiend 9

Oops, forogot to append this :oops:

Credit:-

Many thanks to lampmaker for the solidworks assembly. Brilliant!

http://www.thingiverse.com/thing:29513

Link to post

Share on other sites