I can take some encouragement form this statement. My homemade nozzle has a hot zone about 1/3-1/2 that of the UM1 standard nozzle and I think really good performance from a GeoHagen extruder. I'm thinking another factor working in favor of the UM2 is the dual cooling fans. I'm experimenting with compressed air for that and its working pretty well. Its early to tell.

Come on Ian, how did you get those teeth to print?

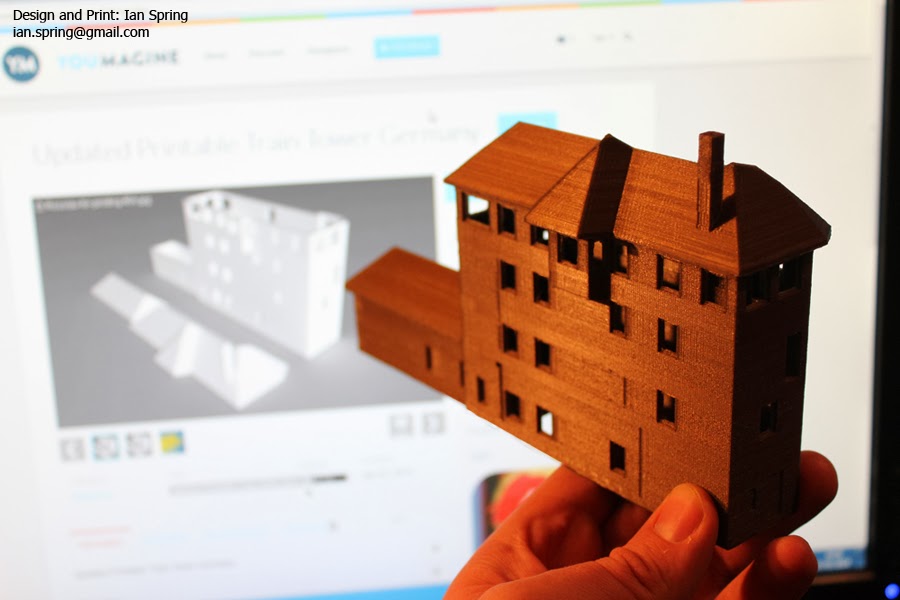

I see now how the model was split turning the face vertical. The picture with the manually added supports suggests that it was all printed as one piece. Nice glue joint anyhow. How does it look straight on to the splice? Don't get me wrong, its really nice work

mmm that was one single.. standing up print... no glue...no splitting... one piece... hand on bible for this one !! :-)

.thumb.jpeg.0b7a05eafc09add17b8338efde5852e9.jpeg)

Recommended Posts

Top Posters In This Topic

362

282

221

179

Popular Days

Jan 5

30

May 12

26

Jan 13

23

May 1

22

Top Posters In This Topic

ian 362 posts

cloakfiend 282 posts

skint 221 posts

SandervG 179 posts

Popular Days

Jan 5 2014

30 posts

May 12 2014

26 posts

Jan 13 2014

23 posts

May 1 2014

22 posts

Popular Posts

kmanstudios

Took me forever to do this. And it is still rougher than I would have liked. 3D concept rendering: Finished piece:

kmanstudios

I just finished this. It was a multi-part print for ease of painting. Some of it I am not sure what happened...but hey, it is purty....And, I am unanimous in that ? Test Render Parts

gr5

Bath interferometers. I have made about 20 of these for people who use them to test their telescope mirrors. They are amazingly accurate and can do better than a $40,000 Zygo PSI optical tester. Th

Posted Images

Nicolinux 288

Yeah, me too. I thought the same. But maybe it would suffice to just bend the metal holding the right fan so it is aimed a bit lower.

Link to post

Share on other sites