well working on two things! first is still my model space ship and here are the stairs, with some international scale references! a dime, penny, Ha'penny and a 10 Eurocent piece!

The detail is just phenomenal, and that is still nowhere near maximum resolution,

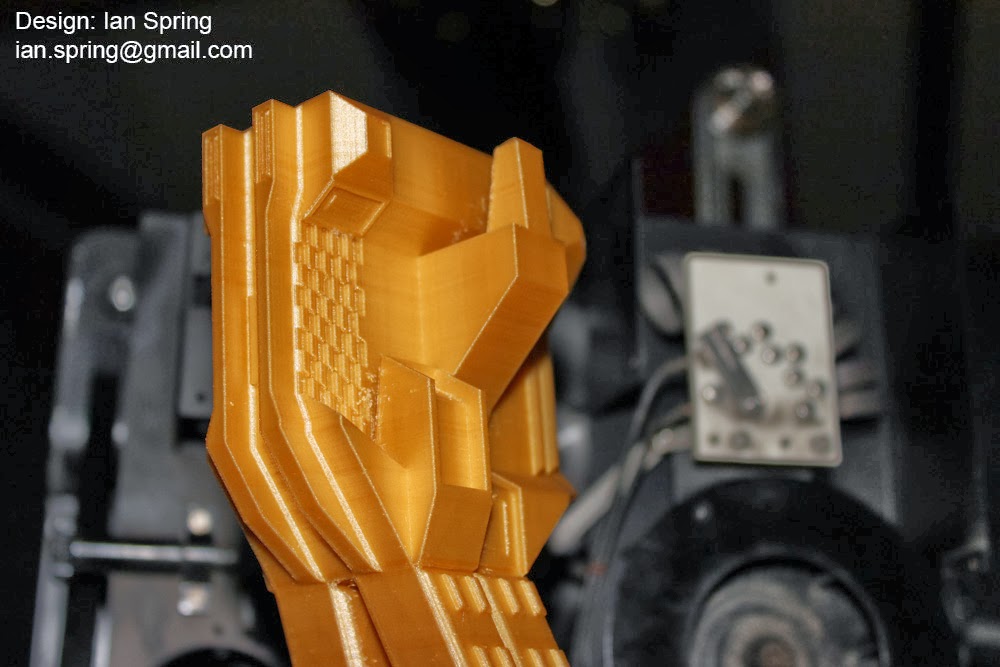

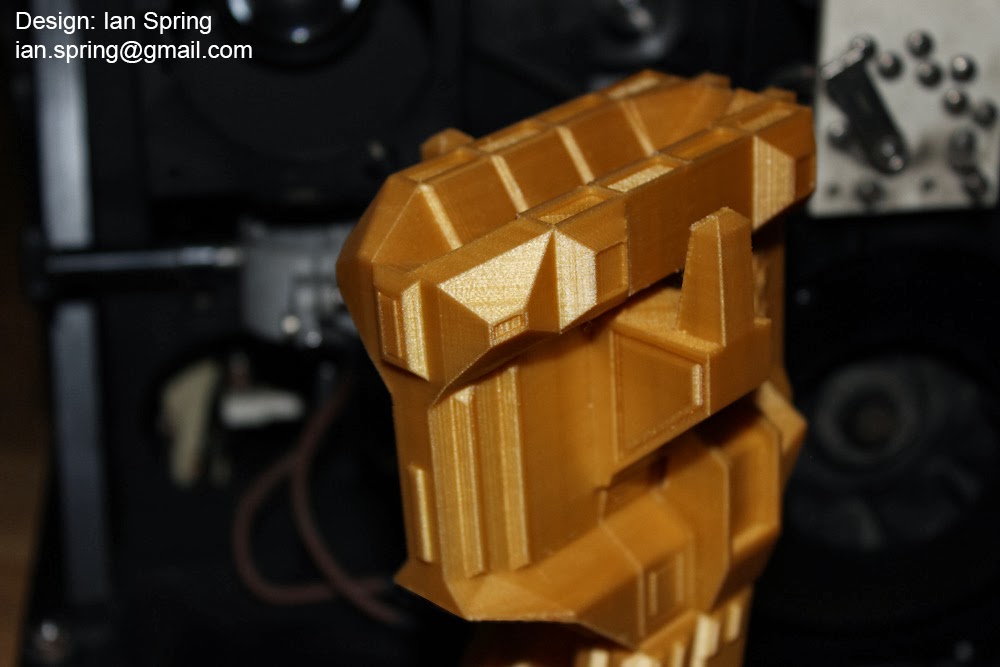

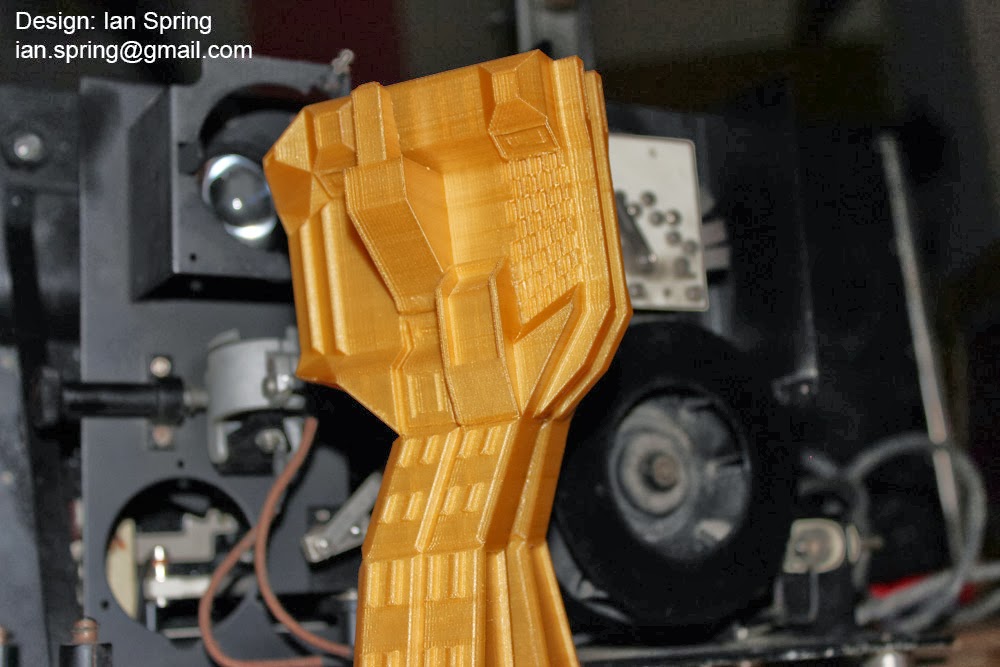

aaaaaaand now for something a bit more, erm, ban-able? (i hope not!)

Fear not though. its an airsoft / bb-gun / toy gun. decided i wanted a gas blow-back "bullpup" rifle to add to my small collection, but the cheapest one is close to £400, so though "why not make my own" and i am ![]()

.

.

.thumb.jpeg.0b7a05eafc09add17b8338efde5852e9.jpeg)

Recommended Posts

Top Posters In This Topic

362

282

221

179

Popular Days

Jan 5

30

May 12

26

Jan 13

23

May 1

22

Top Posters In This Topic

ian 362 posts

cloakfiend 282 posts

skint 221 posts

SandervG 179 posts

Popular Days

Jan 5 2014

30 posts

May 12 2014

26 posts

Jan 13 2014

23 posts

May 1 2014

22 posts

Popular Posts

kmanstudios

Took me forever to do this. And it is still rougher than I would have liked. 3D concept rendering: Finished piece:

kmanstudios

I just finished this. It was a multi-part print for ease of painting. Some of it I am not sure what happened...but hey, it is purty....And, I am unanimous in that ? Test Render Parts

gr5

Bath interferometers. I have made about 20 of these for people who use them to test their telescope mirrors. They are amazingly accurate and can do better than a $40,000 Zygo PSI optical tester. Th

Posted Images

vinay 1

Link to post

Share on other sites