Woah Skint, that looks awesome! I like the poses and robot for scale, it looks like it's a bunch of fun to fiddle with and move around. Congratulations on such a nice print.

Thanks Aaron, I learnt a lot making it, that was the main aim... ( plus my friends 40th birthday was 3 weeks ago, I`m late lol ). Still a few bits to add.

Now that its almost finished, I look at it and wish I had been more patient and printed it at much better settings... but 3 weeks late would of turned into 6 weeks ![]()

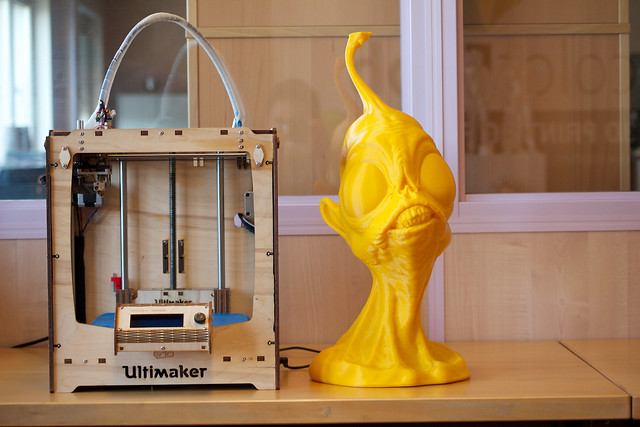

Its so cool being able to just design and build whatever you want isnt it!! I wish this technology was this available when I was a kid.

Now.. I need a new project. Any ideas? ![]()

@Braddock....how`s the T800 Head coming along lol

.thumb.jpeg.0b7a05eafc09add17b8338efde5852e9.jpeg)

Recommended Posts

Top Posters In This Topic

362

282

221

179

Popular Days

Jan 5

30

May 12

26

Jan 13

23

May 1

22

Top Posters In This Topic

ian 362 posts

cloakfiend 282 posts

skint 221 posts

SandervG 179 posts

Popular Days

Jan 5 2014

30 posts

May 12 2014

26 posts

Jan 13 2014

23 posts

May 1 2014

22 posts

Popular Posts

kmanstudios

Took me forever to do this. And it is still rougher than I would have liked. 3D concept rendering: Finished piece:

kmanstudios

I just finished this. It was a multi-part print for ease of painting. Some of it I am not sure what happened...but hey, it is purty....And, I am unanimous in that ? Test Render Parts

gr5

Bath interferometers. I have made about 20 of these for people who use them to test their telescope mirrors. They are amazingly accurate and can do better than a $40,000 Zygo PSI optical tester. Th

Posted Images

wallan 0

Posting a WIP of my latest print.

Model is printed in 16 parts.

That way I don't need any support(saves on print time and material), can print the part as vertical as possible (gives the best surface), have parts that not are to tall compared to height(won't fall that easy) and loads into Cura with no problems(there are some problems with to many polygons).

I printed one in ABS and one in PLA in order to find out if I prefer filling and sanding or using Acetone.

I think that Acetone applied with a brush probably is the best way if I want to preserve very small details but I don't like inhale to much of that stuff or to change workplace in order to get better ventilation.

When it comes to PLA i brush on filler in stead of spraying.

That way I can add it more precise and only apply where it's needed.

Plan is to post WIP pictures of the PLA model if there is any interest in me doing so.

Time to start to apply some filler and start sanding.

Same grey can already be seen on the model.

That's Aves Apoxie.

I have used some in places where I got some holes in the model because I forgot to turn on upper layers.

It will also be used to make some garments for her later on.

Link to post

Share on other sites