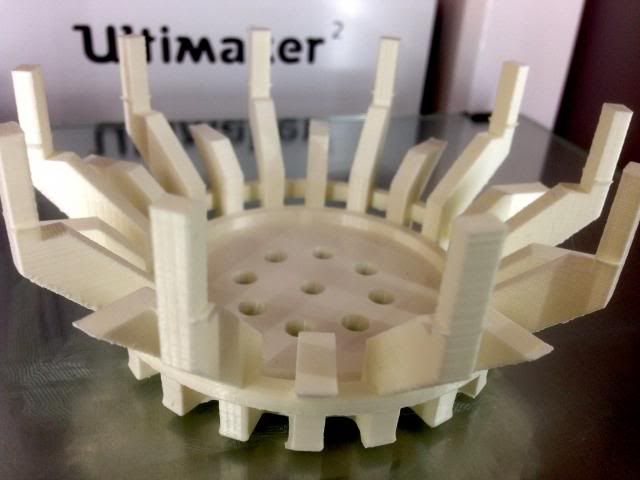

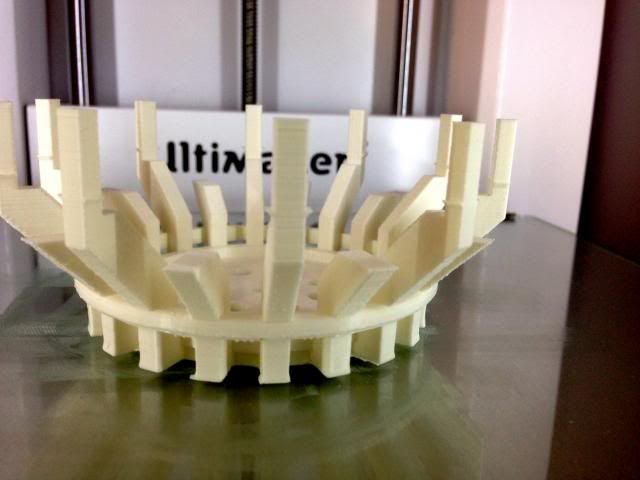

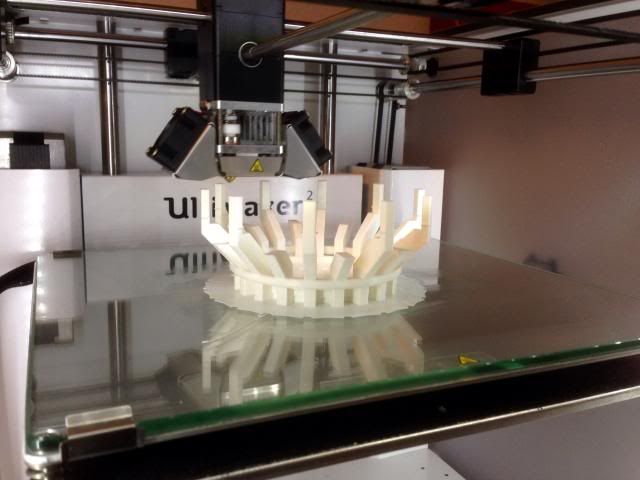

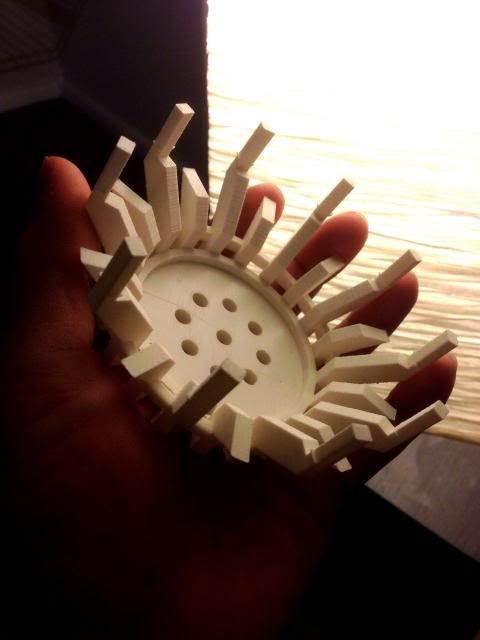

White PLA

Room Temp 13c very cool or 55f

Layer Height 0.1

Speed 30%

Print Head 205c

Heat bed 78c

Infill 20%

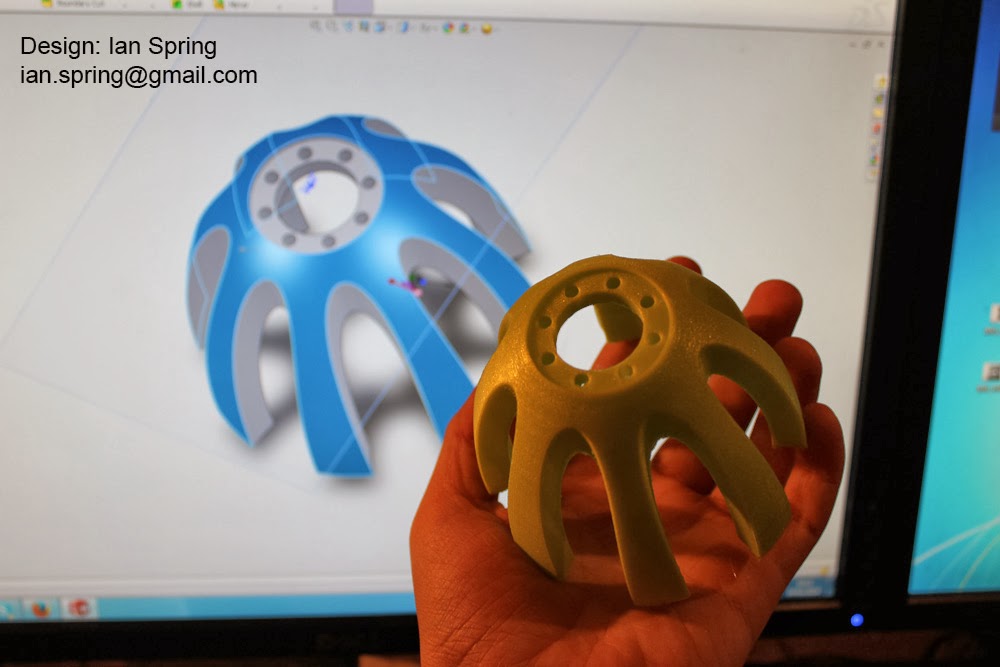

I didn't level my bed correctly I think it was to close to the print tip the edges are not so good, MY Fault but it still came out pretty good... ![]() Anyone have any Tips on White PLA?

Anyone have any Tips on White PLA?

.thumb.jpeg.0b7a05eafc09add17b8338efde5852e9.jpeg)

Recommended Posts

Top Posters In This Topic

362

282

221

179

Popular Days

Jan 5

30

May 12

26

Jan 13

23

May 1

22

Top Posters In This Topic

ian 362 posts

cloakfiend 282 posts

skint 221 posts

SandervG 179 posts

Popular Days

Jan 5 2014

30 posts

May 12 2014

26 posts

Jan 13 2014

23 posts

May 1 2014

22 posts

Popular Posts

kmanstudios

Took me forever to do this. And it is still rougher than I would have liked. 3D concept rendering: Finished piece:

kmanstudios

I just finished this. It was a multi-part print for ease of painting. Some of it I am not sure what happened...but hey, it is purty....And, I am unanimous in that ? Test Render Parts

gr5

Bath interferometers. I have made about 20 of these for people who use them to test their telescope mirrors. They are amazingly accurate and can do better than a $40,000 Zygo PSI optical tester. Th

Posted Images

ian 32

copied text from my ultimaker2 blog site tonight. with the fresh print off the plate :-) :-) :-)

Ultimaker2 allows you to fill your living space with beauty and culture.

If you were ever amazed at history and always admired elements of the past.

Now with your ultimaker2 sitting beside your laptop. you can download a piece of 3d scanned history and print your own miniture infront of you.

Imagine seeing an amazing roman column with a thousaned little details.. you look up at it and try to contemplate how people did such incredible things...Then you take your camera...make some photos and convert that to a printable 3d file and click print.

You can sit down at your desk.. worry about the next big business decision and at the same time... run your fingers along this piece of historical design and wonder... :-)

Link to post

Share on other sites