Colorfabb print was at 195C and Ultimaker blue was at 210C. Both had a bed temp of 60C and were printed at 20mm/sec with a layer height of 0.06mm. I went for a lower temperature with the colorfabb because I found that it produced better results and a smoother finish as can be seen in the image below.

Left 195C, Right 210C

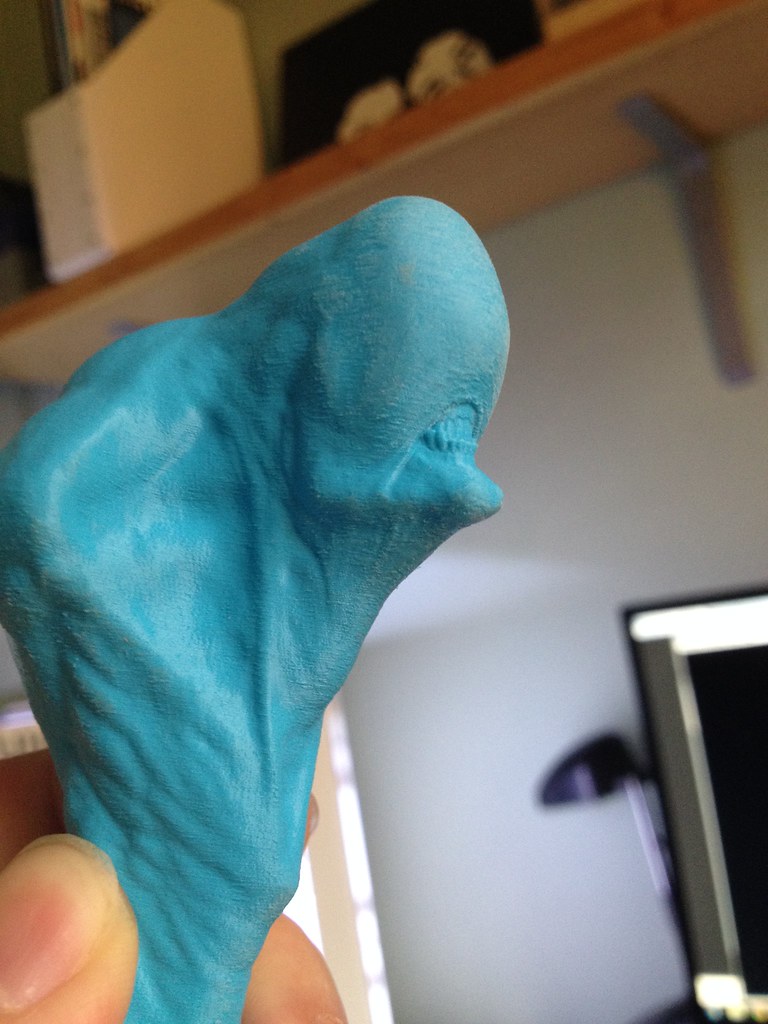

Its clear from the first comparison images that the colorfabb material is a lot rougher on the over hangs and noisy areas but it does seem to have a very slightly smoother surface in areas of low noise. Over all though it appears that I'm getting far superior results with the Ultimaker material. I'm currently printing the small alien head above in Ultimaker blue and I can already see that It is far better in quality than the colorfabb prints. I will post the results later tonight when I get home from work.

I also printed the alien creature again from the same Gcode as before, this time in colorfabb. I wanted to see how the quality improved on larger prints. The results weren't bad but there was a problem when printing the supports as can be seen below. Unfortunately I wasn't in the room when it happened so I cant be sure as to what caused it.

I think that the colorfabb did a good job of capturing a lot of the detail but as you can see in the images below it also has a much rougher surface than what I got previously from Ultimaker blue.

In summery I think I'm going to stick with Ultimaker filiments as I feel that I'm getting an over all better quality print with it. I will continue to do some testing with it in the future but for now I want to concentrate on making more stuff to print.

.thumb.jpeg.0b7a05eafc09add17b8338efde5852e9.jpeg)

Recommended Posts

Top Posters In This Topic

362

282

221

179

Popular Days

Jan 5

30

May 12

26

Jan 13

23

May 1

22

Top Posters In This Topic

ian 362 posts

cloakfiend 282 posts

skint 221 posts

SandervG 179 posts

Popular Days

Jan 5 2014

30 posts

May 12 2014

26 posts

Jan 13 2014

23 posts

May 1 2014

22 posts

Popular Posts

kmanstudios

Took me forever to do this. And it is still rougher than I would have liked. 3D concept rendering: Finished piece:

kmanstudios

I just finished this. It was a multi-part print for ease of painting. Some of it I am not sure what happened...but hey, it is purty....And, I am unanimous in that ? Test Render Parts

gr5

Bath interferometers. I have made about 20 of these for people who use them to test their telescope mirrors. They are amazingly accurate and can do better than a $40,000 Zygo PSI optical tester. Th

Posted Images

leoddc 74

@ Aaron: Cool flashlight.

So I've been doing a bit more testing with the colorfabb filament and this time I'm using the bluegrey that I purchased.

I've done some comparison prints between colorfabb and ultimaker blue filament.

Colorfabb on the left, Ultimaker blue on the right.

Colorfabb print was at 195C and Ultimaker blue was at 210C. Both had a bed temp of 60C and were printed at 20mm/sec with a layer height of 0.06mm. I went for a lower temperature with the colorfabb because I found that it produced better results and a smoother finish as can be seen in the image below.

Link to post

Share on other sites