You'd either need a sort of gear system in each wheel then to switch between rotor/wheel action, or have 2 axes going to each wheel, one that drives the rotor at a much higher rpm and one for the wheel rotation.

That still doesn't solve tilting the wheels inwards on takeoff

Tilting may work (or not) with a single, strong servo motor in the center of the body, which turns bowden cables to make the tilting move. I don't like gears much, but that could work, too.

Yes, but you'd need something "gear'y" to be able to overcome the speed difference between wheel rotation (I assume we were talking about driving the thing on the ground as well?) and rotor rotation.

If the wheels are just some kind of nice looking landing gear, forget what I said ![]()

Just remember that a quadcopter requires that two props run counter to the other two. This may cause problems with your combined wheel prop design.

@Anon, either you fix that in the software(just let two wheels run backwards), or put in an extra gear/ reversing transmission.

I think the first option is preferred as to keep the maximum efficiency.

Actually, what about something way cooler. We put freewheeling wheels in there, and use the air to propel the robot ![]() Like a hovercraft on wheels

Like a hovercraft on wheels ![]()

Actually, what about something way cooler. We put freewheeling wheels in there, and use the air to propel the robot

Like a hovercraft on wheels

Sounds very cool but you'd need a seriously advanced join for the front wheels.

- Wheels straight up, rotor pointing backwards to drive

- Wheels straight up but turned to take a curve. The rotor needs to remain pointing backwards as to not hit the body. So it needs to hinge.

- Wheels rotated in flying mode.

Even if the rotor can rotate a bit (which I assume it does for steering in the air), the chances of hitting the body are still there (or you need to use the rotors to turn and do it very slowly)

I've printed a v-tail a few weeks ago and started assambling it. Important for design from my point of view is to define easy available reference parts for reserving the right spaces e.g the ESC's and the sensors if they are seperately. For example I use an arduino mini pro instead of a predefined multiwii board as its small and light but needs additional sensor boards like GY85.

Maybe this helps a bit in the process :-)

Are you going to be part of this group who is going to design their own Multirotor Drayson? ![]()

Sounds like you already have some experience.

I was planning to design and build my own quad-copter for the winter, but after reading this topic perhaps It's a better idea to participate within this group.

Although I'm not an expert in 3D modeling (learned it hands-on) I can make an attribution with it.

I was planning to design and build my own quad-copter for the winter, but after reading this topic perhaps It's a better idea to participate within this group.

Although I'm not an expert in 3D modeling (learned it hands-on) I can make an attribution with it.

Awesome! ![]()

Nop, it flies without flipping the sides:

I really like that (first) video!

The spherical one could be game changing - make the 'cage' into wheels and you have an incredibly mobile vehicle that could truly be all terrain with a prob guard built in - you could probably forget the drive on the wheels - just use the prop!

WOW to that one!

Are you going to be part of this group who is going to design their own Multirotor Drayson?

Sounds like you already have some experience.

If it´s ok for you - sure. But I have only some experience in doing wrong cabling/soldering and toasting some sensor boards :-)

Mine is still not airborn and I fear, within the next 3-4 weeks it wont as I´m on vacation soon (yipeee...)

Just as a design stimulus: I took this one and shrinked it by 50% http://www.thingiverse.com/thing:94920

was hard to find motors that fit in therefore my note regarding components.

If I´m alowed to give a suggestion:

I would suggest to start with some kind of requirement collection/list first to get the whishes of everybody involved, then select the basic type (e.g. quad, hexa, octo, v-tail, ..), calculate the requied trust, select the suitable components and then go into the final (real) design...

I would suggest to start with some kind of requirement collection/list first to get the whishes of everybody involved, then select the basic type (e.g. quad, hexa, octo, v-tail, ..), calculate the requied trust, select the suitable components and then go into the final (real) design...

That kind of approach would be preferable I suppose........

...

If I´m alowed to give a suggestion:

I would suggest to start with some kind of requirement collection/list first to get the whishes of everybody involved, then select the basic type (e.g. quad, hexa, octo, v-tail, ..), calculate the requied trust, select the suitable components and then go into the final (real) design...

What drayson said.

Just something that popped to my mind:

We could dedicate (part) of next ulti-evenings to this, or organize another meetup, with a teleconference(FabLab Polycom could be a suitable system) for all the people abroad. Get this thing 'off the ground' ![]()

Following on from Drayson’s suggestion, I would like to propose an initial list of requirements. The idea would be to consider it as a mere starting point from which requirements can be amended, removed, added to, etc.

I've tried to start with a reasonable set of requirements. Indeed, the following “Must Have” section is loosely based on what an original DJI Phantom (http://www.dji.com/product/phantom/feature) could do about two years ago.

Must Have:

- Flight time of 12min min. (ideally 15-20min)

- Powerful enough to carry a lightweight camera (e.g. GoPro) and small accessories (e.g. First Person View “FPV” transmitter)

- GPS and Decent stabilization system (“Position Hold”, “Return to home”)

- Frame/arms strong enough to support a fall from a height of 2m without breaking

- Standardized parts wherever possible (motors, propellers, etc.)

If we feel especially adventurous, we could also have a list of stretched goals. :wink:

"NIce to Haves":

- Flight time of 20min or more

- Frame/arms strong enough to support a fall from a height of 5m without breaking

- Propeller guards

- Waterproof

The big quadrocopter are cool. But I like the smaller ones more. The small ones are more flexible with the flight area and are more mobile to carry around.

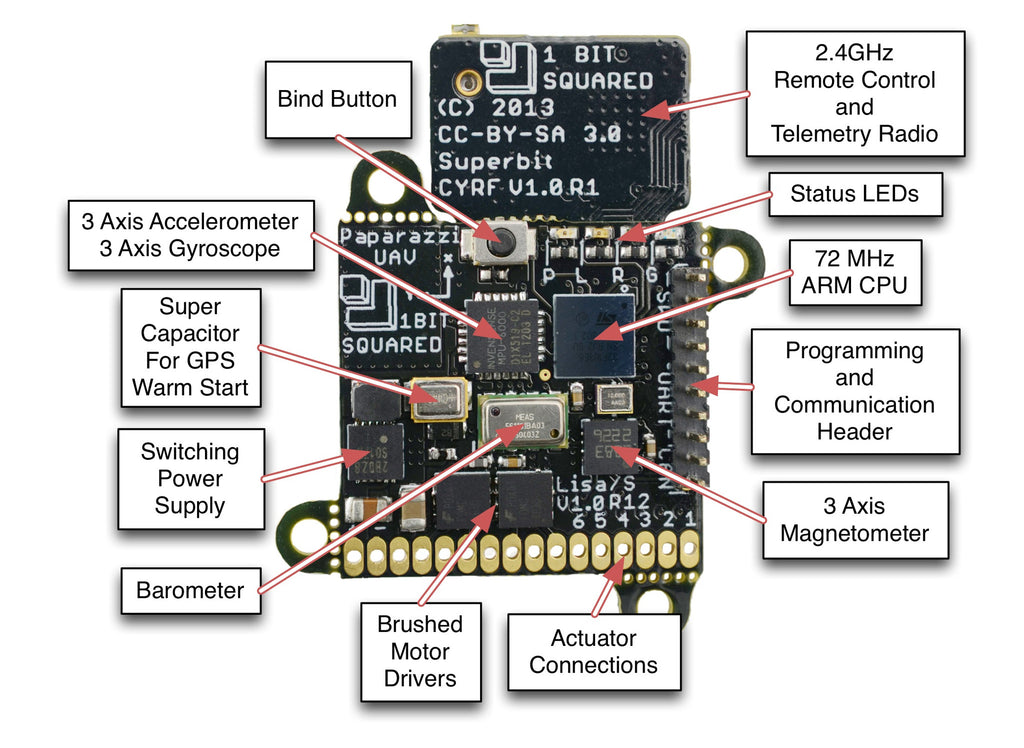

I really like the Lisa flight controller and the paparazzi auto pilot (open source).

The new "Lisa/S" by http://1bitsquared.com/ has Accelerometer, Gyroscope, Magnetometer, GPS, Barometer and can sent the telemetry data back to the ground station.

A small frame for a quadrocopter is faster to print, too. ![]()

More info about the Lisa/S in this interview (starting at 1m50s):

The big quadrocopter are cool. But I like the smaller ones more. The small ones are more flexible with the flight area and are more mobile to carry around.

I really like the Lisa flight controller and the paparazzi auto pilot (open source).

The new "Lisa/S" by http://1bitsquared.com/ has Accelerometer, Gyroscope, Magnetometer, GPS, Barometer and can sent the telemetry data back to the ground station.

A small frame for a quadrocopter is faster to print, too.

More info about the Lisa/S in this interview (starting at 1m50s):

Smaller ones are also cheaper, making it easier to join the project.

I would love to print&build a small quad-copter. But I do not have loads of cash laying around. So I think making a "ballpark" BOM would be important to start with.

Smaller ones are also cheaper, making it easier to join the project.

I would love to print&build a small quad-copter. But I do not have loads of cash laying around. So I think making a "ballpark" BOM would be important to start with.

The small "autonomous" machines are not that cheap. Way more than the toys in this size. But the "autonomous" functions are the next, interesting steps in this field.

The basis version of the Lisa/S without a frame and without motors is $410. I would use some old motors of one of my Hubsan. The version with motors and frame is at $500. :(

EDIT: And I have already a Spectrum DX6i Controller. So I'm a little bit biased. But I have no connections to 1bitsquared.

All good points. So,

- how much are people willing to spend on the bill of materials? Personnally I would be ok with the cost of the LISA/S provided that it doesn't discourage anyone

- The guys behind 1bitsquared are attending an event in Delft, NL this week (http://www.imavs.org/2014/). Is there any chance for one of our Dutch friends to see them there?

.thumb.jpeg.0b7a05eafc09add17b8338efde5852e9.jpeg)

Recommended Posts

Top Posters In This Topic

22

21

20

17

Popular Days

Aug 12

18

Aug 13

17

Jul 30

16

Jul 31

11

Top Posters In This Topic

SandervG 22 posts

woofy 21 posts

gr5 20 posts

closedcircuit 17 posts

Popular Days

Aug 12 2014

18 posts

Aug 13 2014

17 posts

Jul 30 2014

16 posts

Jul 31 2014

11 posts

Posted Images

Blizz 53

You'd either need a sort of gear system in each wheel then to switch between rotor/wheel action, or have 2 axes going to each wheel, one that drives the rotor at a much higher rpm and one for the wheel rotation.

That still doesn't solve tilting the wheels inwards on takeoff

Link to post

Share on other sites