tinkergnome 927

Follow the first rule on 3D-printing - take a seat and calm down a bit...

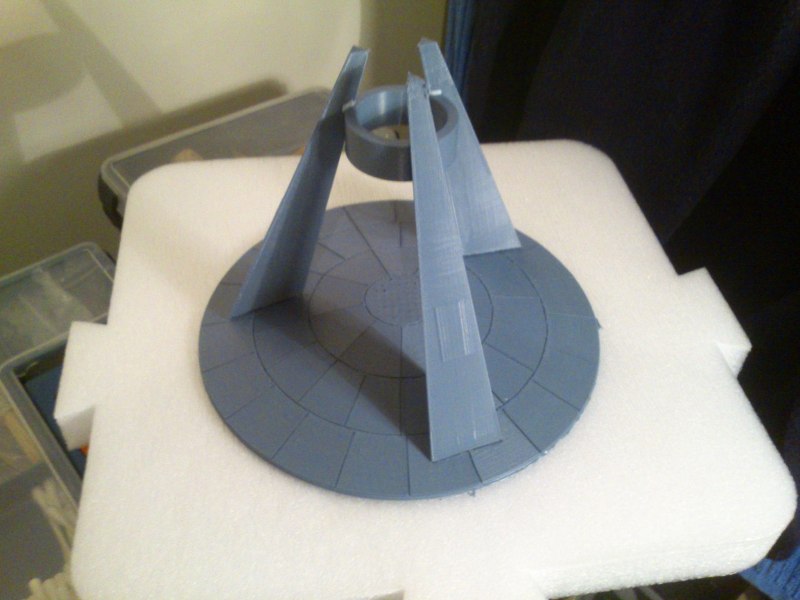

Sounds like a very warping friendly geometry... something like a L-shape?

You betrayed nothing about the printer, the printed material, heated bed (yes/no)?

A good attempt can be to use a very large brim (20 lines or more) and mark the brim with blue tape after the first layer.

Don't give up!

.thumb.jpeg.0b7a05eafc09add17b8338efde5852e9.jpeg)

Recommended Posts

skint 61

Oh no 0235 you do sound pretty pi$$ed off ...Is this an unheated bed on a UMO?

Link to post

Share on other sites