Yeah I have printed other faun shrouds and had problems with having the whole nozzle exposed like that with the air rebounding off the glass or larger prints and cooling the temp sensor block.

Also why have you decided to put a deflector covering one side where the missing hot end goes?

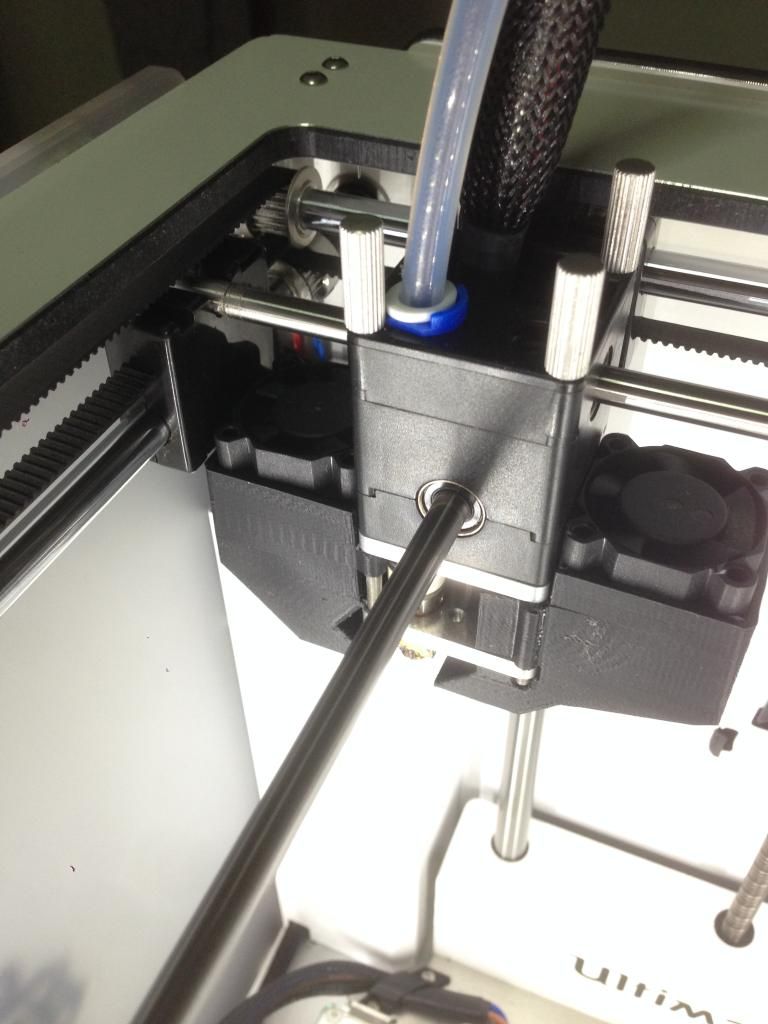

.thumb.jpeg.0b7a05eafc09add17b8338efde5852e9.jpeg)

Recommended Posts

DidierKlein 729

Hi

Interesting design, i tried my self to have some kind of similar approach to you (Splitting the fan shrouds in two) but using the same type of screws and position as the original one. My design is ugly but i tested it a couple of hours and it seems to print good. I don't have any deformation of the material (PLA).

but i tested it a couple of hours and it seems to print good. I don't have any deformation of the material (PLA).

Do you think they will melt if printed in PLA? (if you print at 230°c for example)

Do you have any problems with the temp sensor (being more exposed)?

I like the idea, does the position of the fans increase the airflow a lot (compared to the 45° position?)

Link to post

Share on other sites