thehitman04

-

Posts

56 -

Joined

-

Last visited

Never

Content Type

Forums

Events

3D Prints

Posts posted by thehitman04

-

-

Ill get a picture on as soon as i get out of bed lol, yeh i agree the supports are great. I just wish i could turn them on constantly

-

It is for this, but still not for another

-

Ive got it on touching buildplate since i started it. That makes sense but 2 of the models were almost identical in the way the overhang is, one did and one didnt. Ill have a look at that setting though and see if i can find out why its not doing it all the time.

Thanks

-

thats what i thought, but on one of the ones ive done it definately would have been as it was a 90 degree overhang, the only 2 models its done it on is this one, and a duplo brick type of thing. the brick was the first and i assumed it was the program the guy had used to make the file that did it, it didnt have the supports in cura either. That one was a 90 degree overhang too.

Got me baffled

-

how come it doesnt print on every model?

-

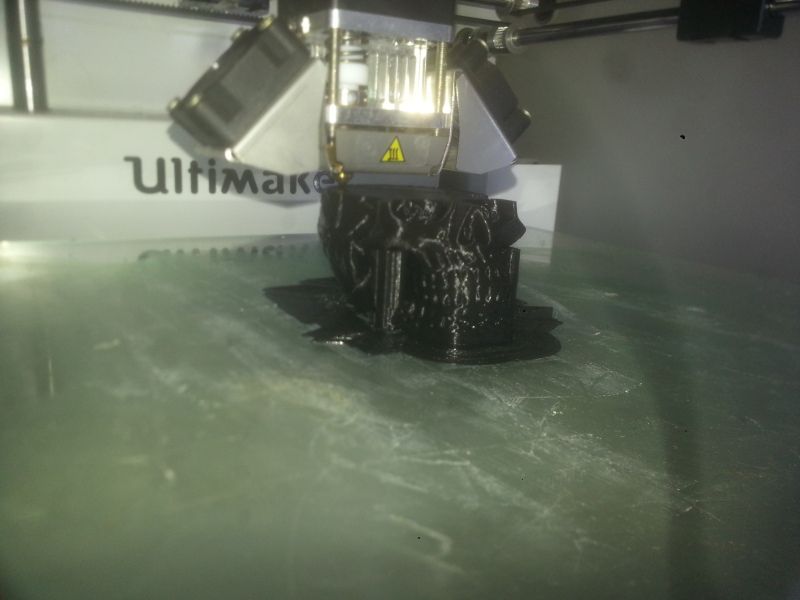

Hi, just printing something now that when i had it in meshmixer and in cura it has no supports at all

http://www.thingiverse.com/thing:29114/#files

This is the file in question, now when it prints its printing with its own support system. Now im not complaining i think its great but what is adding the support?

Alot of things i do id like this same support network for but i dont know how to add it, i know i can add them in meshmixer but i much prefer this support structure as its alot more robust

-

It wasnt displaying properly on my phone, worked on my pc though

-

Just been looking at that taulman nylon, looks nice, especially in the red glaze. I assume the 618, 645 and 680 are their grades but i cant find info on them on their site

-

Im gonna be making some inlet manifold parts soon and was wondering if pla would withstand petrol? Ive searched google but dont get any actual answer. If jts not suitable, is there a material i can print with on a um2 that would do. Some nylon perhaps?

-

It smells the same to be honest, and yes i bought it from faberdashery direct. Its sorted now anyway, i did a few more in blue then back to black and it worked this time round. Who knows ? may have been something clogged or something

-

Yes its pla, thats what i ordered anyway. Is there a way to tell by looking at them?

I printed a few things in blue last night and they came out great

-

quick look is it came through fine but as my bed level is out slightly didnt print properly, but material flows no problem

-

Ill try now and re install the blue, do you mean does it smell different when its heated up ?

I havent measured the nozzle but the filament is 2.84mm which is what its meant to be i think. Id have to get some more wires from work to measure the bore but i think its around the .4 mark as im using 0.34 wires and the clearance around isnt a lot

-

Sorry i was in a rush to leave when i posted, its an ultimaker 2, i tried at whatever the standard is, 220? And at 230 i think. Im not entirely sure where the problem lies to be fair, but it was printing in the ultimaker blue not long before i swapped it, which was printing fine. I can put the blue back and run it if you think it may help?

-

Hi, i recently got some of this for some badges im printing but i cant get it to work, it kind of just globs up the extruder and i have to heat up, insert filament then cool and remove which is working fine to un block it but then upon re installing it does it again. The nozzle is totally clear as ive had a 0.3 thread wire inside and theres no resistance but not sure what to try at the moment.

Any ideaS?

-

So far my experience with Faberdashery has been top notch.

Ive literally just got mine through, bought 100m of black and got what looks to be about 10m of gold free. It came in 2 days and cannot fault it one bit

-

all of those are at the high speed setting, ive printed out a trophy top yesterday at 75mm/s and its really good. the model itself isnt the best but the print quality is good

-

Ive got meshmixer but havent looked into very much yet. Heres the model

http://www.thingiverse.com/thing:252935

a guy has also posted a new version with the meshmixer "beefy" arms which he says he did on meshmixer to sort the base and make it solid, so ill make sure i get on it when i get home

-

Hi all, i recently downloaded a model which appears to be a 3d scan of a trophy. Which i want to replicate for a game we play at work with a custom base ill design myself. The problem is the base of the model is very jagged and the model is hollow (which is why i assume its a 3d scan.) So i need to import it into something, flatten the bottom and infill the model to allow printing, does anyone have any recommendation for what program to use?? I have Sw2013 which will import some stl's but not all, depends on the complexity of the model i think so if i can do it in that then thatd be great but i just dont know how to go about it at the moment

-

I had also wondered this the other day, thanks for the info

-

There are torrents for nx6 and probably higher, i had 8 but went back to solidworks 2013 instead. Depends which way your moral compass points lol

-

Up near durham for me. But id probably be up for a hike lol

-

Ive just done this and it worked for me so id go with what the guys are saying

-

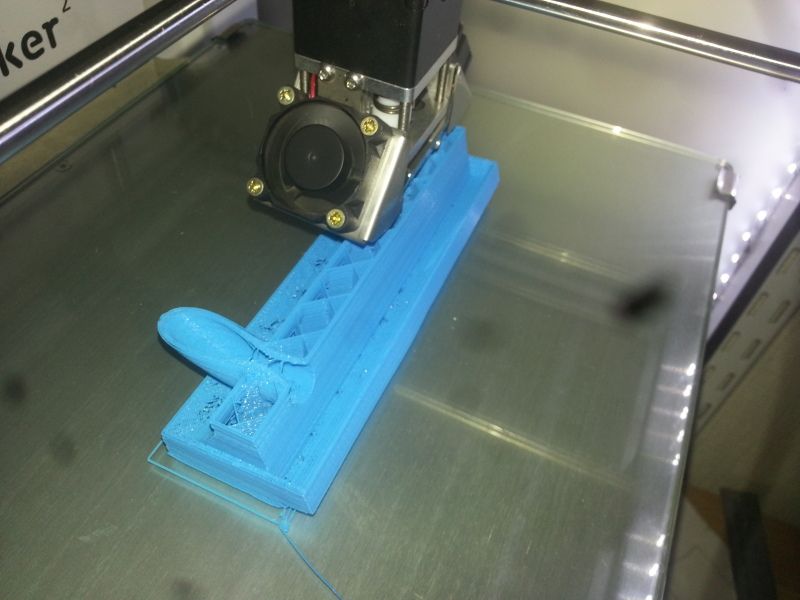

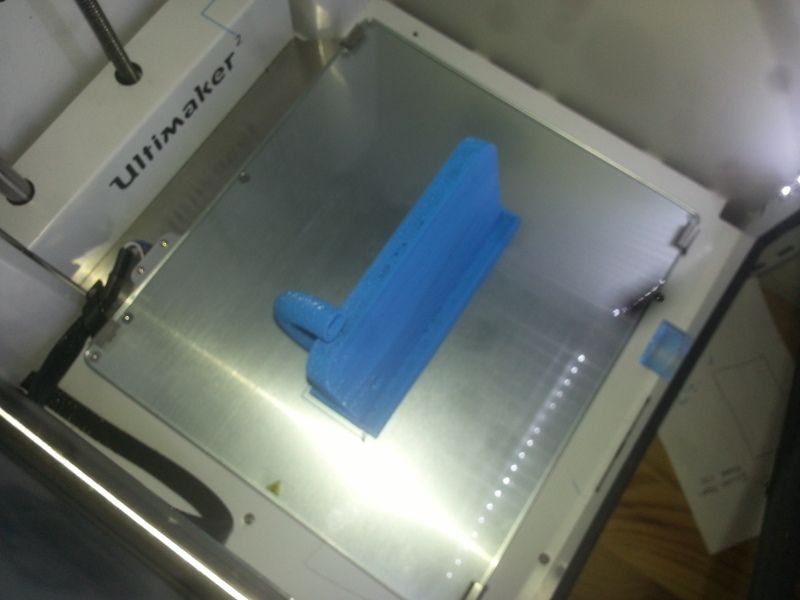

I put that on yeh, and yes its alot tougher getting things off now lol. Anyways heres a few things ive printed

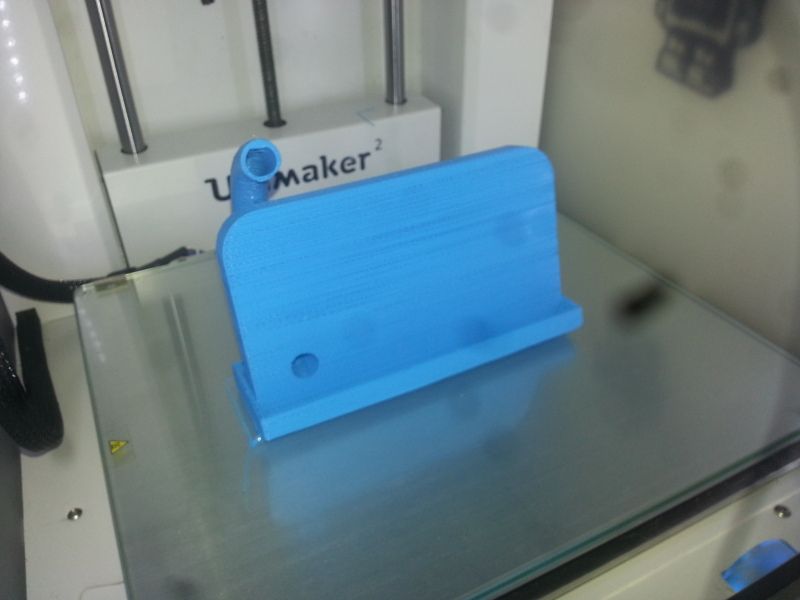

These are a phone stand i designed for the s3 mainly for watching videos, the channel is to redirect the sound to the front instead of the back

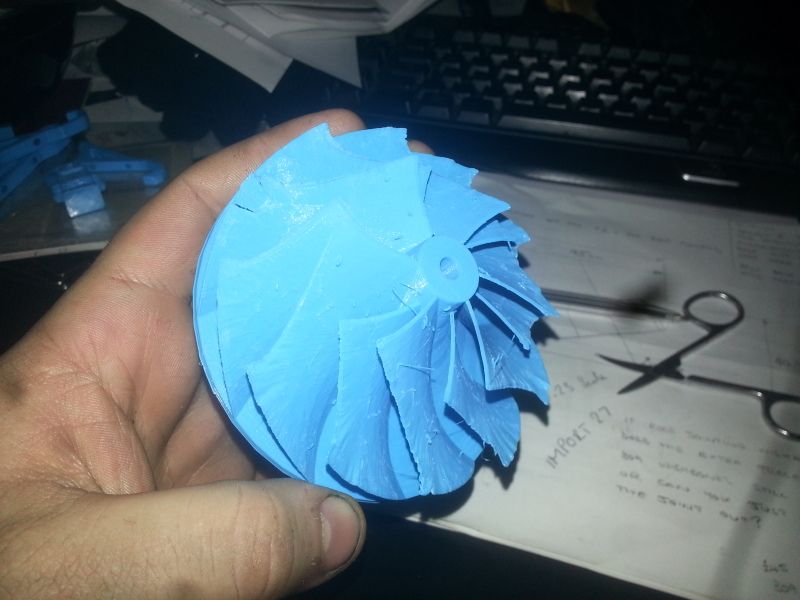

a gt4088r compressor wheel, took a long time and the quality is ok but the fins are thin and havent came out amazing. Still happy with it though

the mark II phone stand, alot thinner overall, alot of wasted material removed and a more rigid sound tube. Again quality isnt great as i wanted it as a tester, im happy with sizes so im gonna print another in high quality

petrol friendly filament?

in Coffee corner

Posted

Well i just bought some t glase red and some taulman bridge. Both were a bit of a pain to get onto the bed but after a few tweaks i got them to work.

For the t glase i was at about 230 degrees with 75 degree bed and glue, i also had to print real slow to get it to adhere, i think my initial layers are set at 10-15mm/s and then i even turned it down on the machine by at least half. Once initially stuck down i could crank it up and printing on itself seemed fine, i ended up at 120% of 50mm/s which still stuck fine. One downside to the faster speed was it kept extruding while moving, so if youre moving between points you'd have to adjust filament retraction. For me it wasnt an issue so i left it. Printing thicker at 0.3 or 0.4 layers requires more heat i think and i didnt have much luck with it. The part was quite tough though which i was pleased with, not very clear as i printed at 0.1 layers but did the job nice, it sands up nicely too and is the colour of red liquorice. Seems more flexible than the pla but definately has more strength to it too.

The bridge i think i was about 240 degrees with a 62 degree bed, i got a print off but wasnt that keen on it, now i think its more to do with my impatience really. I printed at 0.3 layers probably quite quickly and he overall asthetics werent great. I was hoping itd be more rigid too, maybe my car parts would be as theyre thicker. I did a glasses frame at 0.1 layers at about 30mm/s and it came out a nic3 finish.

One problem i did have with nylon was getting these little spider web type bits coming off and sticking to everything, i ended up getting nylon stuck to the outside of the extruder which when touching anything pulls up strands. Not much fun but not a massive issue. Finishing was a pain too as i couldnt easily finish the bridge, more to do with the 0.3 layers etc making a much rougher part but still. When trying to sand it it just makes the surface rough and stays there, if your hands are dirty itll absorb dirt well too which isnt nice to look at. Ill keep trying though