feferna

-

Posts

3 -

Joined

-

Last visited

Content Type

Forums

Events

3D Prints

Posts posted by feferna

-

-

I would do this test:

Pla can warp also if the nozzle it's way too close. I can't see the first layer print well enough on that photos, and photobucket zoom it's quite bad.

But I think that:

- First layer way too close to the nozzle. This it's easy to see because it does 'small tidal waves' when doing the infill on the first layer.

- Print a taller 0.25-0.3 first layer height. More material helps adhesion.

- Print slower first layer.

- Flip the glass. Who knows.

- Some pla brands stick worse than others. For me colorfabb, faber, Smartmaterials never gived me this problem, but with some china pla I got very weird adhesion.

Thank you. I notice these "tidal waves" when printing the first layer. Looks like the nozzle was really too close.

For now, I got a good result. I tried to level the buildplate again making it a bit more loose and now the material have stick in the plate. Now, I got something like 90% good (I can still notice some small waves when the nozzle pass through some regions).

PS: I also flipped the glass, but I didn't notice anything different.

-

Hello everyone,

It has being almost 6 month since we bought an Ultimaker 2 Extended+, and we were printing things without any problems. However, today I am facing a very bad warping problem in our printer.

The first layer of everything I am trying to print is warping.

I tried the following:

- Leveled the buildplate making the space between the nozzle and the plate smaller: This helped with the warping. However, the layer become too squeezed and the print quality decreased a lot.

- Changed the buildplate temperature to 40C, 50C, 60C, 65C and 70C: no difference in the warping.

- Used some glue: the warping has decreased, but is still present.

- Used a material from another brand: decreased the warping, but it was still present.

I don't know what else should I do. Any clues? Or my 3d printer is broken?

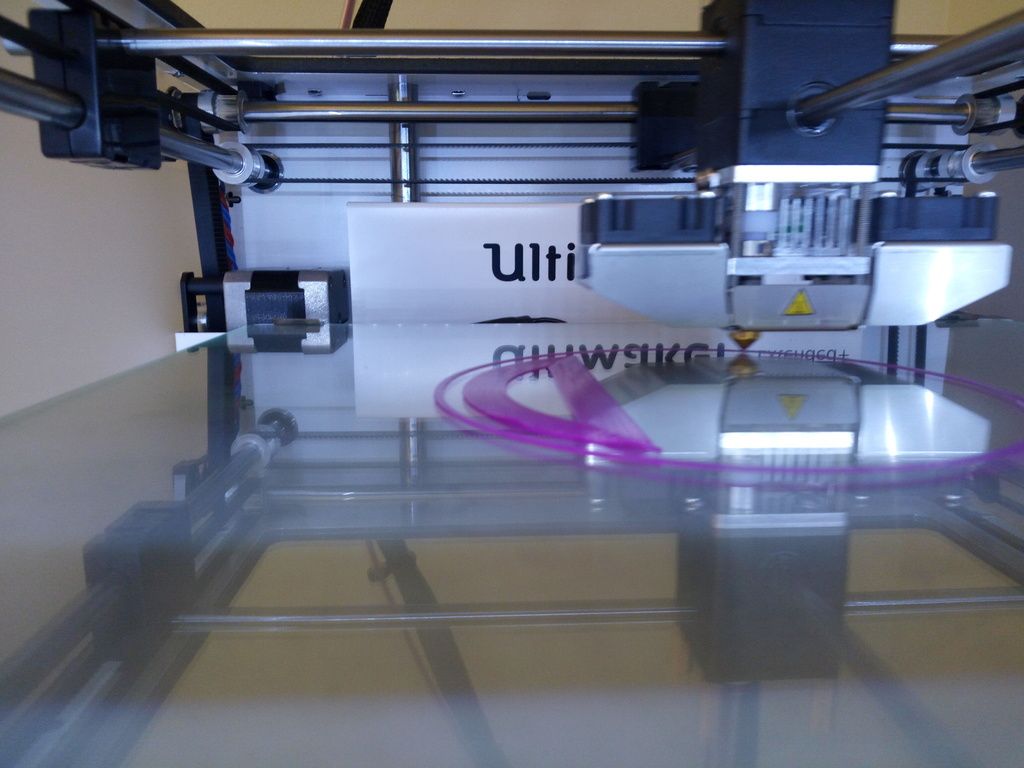

Here are some images showing the warping I am facing:

Ultimaker 2 Extended+ is printing bad support material

in UltiMaker 3D printers

Posted

Hello everyone,

I am facing a problem with my Ultimaker 2 Extended+ printer.

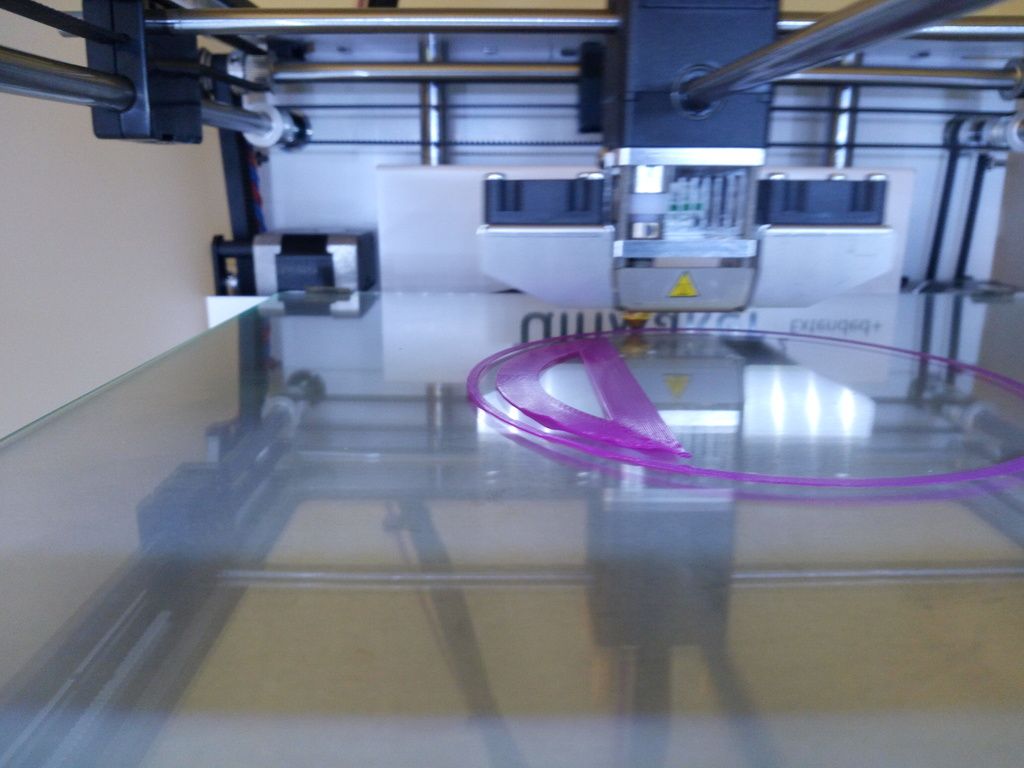

The support material is not being printed in a nice way. I am sending a picture showing my problem.

I saw that the nozzle was hitting the support, and I activate the Z Hop When Retracted, Z Hop only over Printed Parts and Z Hop Height = 0.5 mm. However, the printer is still hitting the support material.

Before that, I tried to use only Z Hop When Rectracted and Z Hop Height = 1.0 mm. However, I was having under extrusion problems soon after the Z Hop thing. So, I modified these options to the option mentioned before.

This was the under extrusion problem I had when I used Z Hop for everything:

So, does anyone know how I can avoid bad support material and under extrusion in my prints?