battzilla

-

Posts

19 -

Joined

-

Last visited

Content Type

Forums

Events

3D Prints

Posts posted by battzilla

-

-

I have my work laptop and desktop at home, and at work i'm constantly changing small variables for printing. Is there any way to link the two computers?

-

3 hours ago, ahoeben said:

Any suggestions? I am trying to disambiguate "window" between window representing the folder that the executable is in and the running application.

Hmmm, good question... I would maybe say something like this:

Once Cura has started, drag and drop the downloaded package into the build space like you would an STL for printing. Restart Cura, and the sidebar gui should be working again.

-

1

1

-

-

WOW! thanks so much for the help, its back up and running just fine now!! 😁

BTW, you're very much correct about the issue. I manually added some folders in my resources for my Artillery Genius printer. Before that no issues, so had to be the cause which you identified already.

And just to give some input about the instructions, everything was very clear and easy to follow except the last part:

I was not sure if you meant an application window folder or the actual application (i'm not too technically savvy). I ended up first dropping the package into the plugins folder and did nothing. Then opened cura and dropped into the work space, restarting and it was applied (i'm sure that's exactly what you said to do, on my end was just a little confused about what "application window" meant).

Anyways, thank you once again!

-

Hello everyone! Im having this issue with the sidebar plug in.. The image shows a warning sign I get after I installed the plugin, and it only lets me send report then cura shuts down.

Not sure whats going on but it caused me to reset my entire cura set up several times, until I realized I was able to delete the corrupt files under ....cura\4.4\plugins\SidebarGUIPlugin . After deleting "SidebarGUIPlugin" cura starts back up just fine like nothing happened.

I really do enjoy this plug in, so I would like to ask if anyone knows how to fix the issue. Thanks everyone!

-

Maybe the one you bought was a .35mm nozzle and cura thought it was .4mm and you got heavy overextrusion?

Yea thats probably it. It was advertised at .4mm so thats what I plugged in. Oh well, not y problem anymore! hahah!

So, what would be the reason for switching to a smaller nozzle size? Bette print quality? Or to achieve lower micron resolution?

-

Is the general shape of the new nozzle the same as the UM one?

These things look IDENTICAL, check them out! I ordered these two and im returning them.

To the left is the one I used which produced all the issues. And to the right is the extra one I ordered as a future replacement part.

The look like the real thing, and even fit perfectly. I thing the issue was in the hole of the nozzle. I dint bother to play around and see what is was. I just wanted to enjoy my printer for once.

-

Here are some shots..

Things would get better than worse..

The one to the left was the last print I did until I swapped them back. The one on the right was literally after I put on the old nozzle!

Basically some layers would load way up and spill out, and some would miss out. So a lot of back and forth on the issues, but everything cleared up after. But yea, extra parts are always a good idea and never skimping out again.

-

Are there any reputable websites where I can buy AUTHENTIC Ultiaker parts? I just bought a .4mm nozzle from amazon and turned out to be complete junk! Spend 8 hours and a lot of filament to figure it out.

Link: (DO NOT BUY!!!)

http://www.amazon.com/gp/product/B00I508ZTA/ref=oh_details_o05_s00_i00?ie=UTF8&psc=1

Im looking for parts which need replacement once a while, like the nozzle or parts on the hot end. I dont mind paying a higher price if it means higher quality parts that dont cause me days of work and headaches. I just want to enjoy my printer for once, so can anyone share some info here?? Thanks!

-

It looks like Z axis issues. What happens is the Z axis moves too little (gets a bit stuck) and then you get overextrusion because even though you request .1mm layer height it moves say only .05mm so you get 2x overextrusion and it sticks out and makes a line that sticks out. Then a few layers later it catches up and does .15mm instead of .1mm so you get 33% underextrusion on that layer. This repeats randomly.

(by the way your pictures are hard to see the settings - I think it's .1mm but the numbers are only 3 pixels high so it's hard to tell).

Usually this is caused by a loose Z nut. When the Z screw rotates, the nut sometimes rotates also such that the bed doesn't go down at all. Or the nut rotates half as much as the screw. Then for the next few layers the nut doesn't move and they are fine, then it moves again and you get another overextrusion. When you home, the nut spins back the other way ready to mess up the next part.

I would take apart the bed - remove the vertical rods out the top, remove the z screw out the top. Disassemble the entire bed enough to get at the Z screw and see if you can make it so it won't rotate. then put it all back together again. My Z nut is locked in tight and never ever moves. This is not the normal design - the normal design allows it to slide around a little but it should definitely not rotate. I prefer my (minor) modification where the Z screw is locked in place permanently.

I got a shimmy to stick in there so the nut would not move... The problem did not go away :/ Im thinking i have extruder issues or possibly something in the hot end. Because, something it goes a full 2-3 layers without extruding very well and it comes out lumpy. so not sure whats goig on..

-

Not quite I understand what was happening here and how you fixed it? Was the bowden tube popping out of the head of the printer? Then again, it's 3AM and I should be sleeping... brain is no worky very good

There was a lot of wiggling on the bowden tube at the extruder, so I took it out, wrapped tape around it and put it back in. It stopped wiggling all over and now its working.. not sure why but the issue is fixed. But its causing problems with prints. check out my other thread.

-

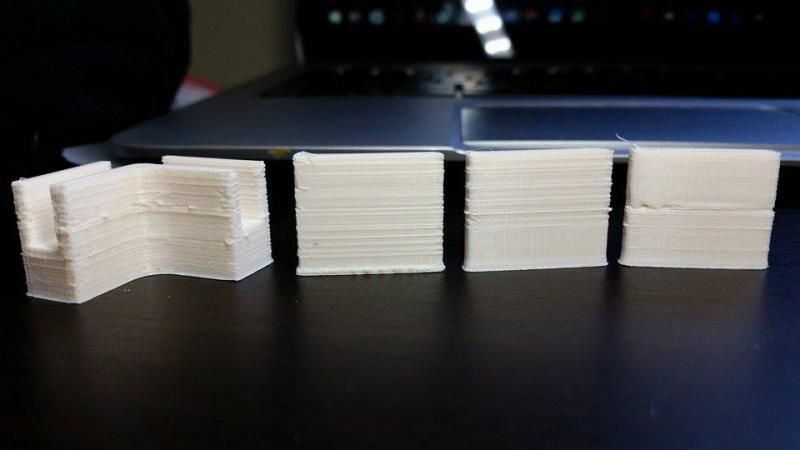

Ok.. so got over some issues of my extruder skipping, and now this!

(In order of when they were made, from left first to right last)

I installed a new nozzle, would this be whats causing the issue? I had black filament in there last week, which burned up causing clogs, so I ended up returning it and replacing the nozzle and switching back to white.

Dond mind the black mark on the first part, it was me marking it with a marker. But the other do have some dark spots. Im thinking it needs to cycle more filament??

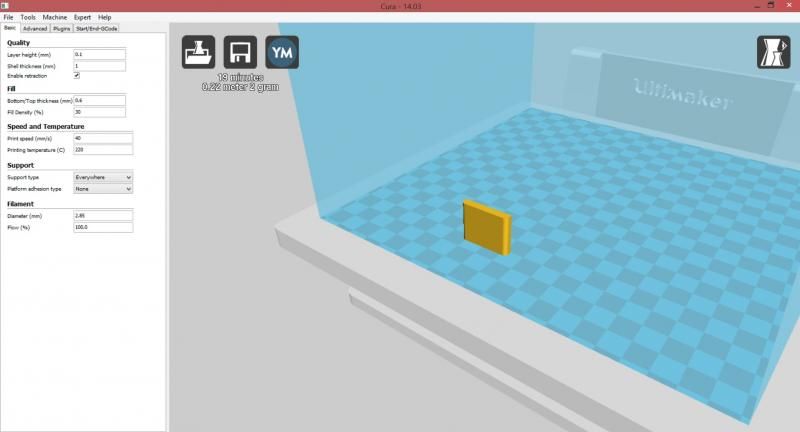

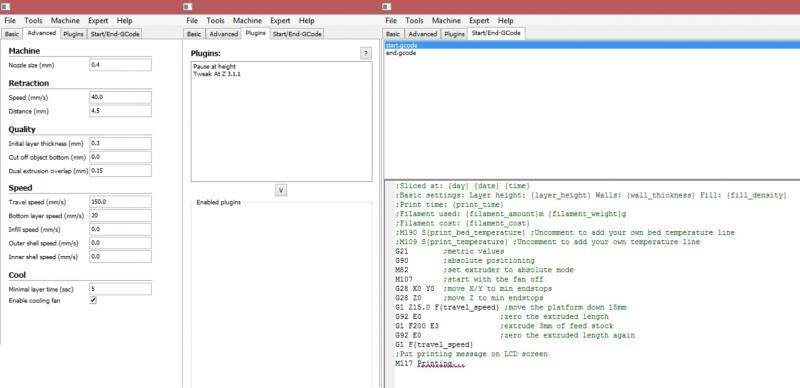

Here are the setting for my UM1:

The part is 25mmx20mmx4mm with a fillet on the front 2 corners. Just a test part..

Should I be changing something up?? How do my setting look? I am printing another part, should be done in about 20 mins.

-

Problem solves, the solution was tightening up the gey nut that holds the hose above the extruder. I used some blue tape to hold it tighter. Looks like there was too much play.

-

Im getting this popping sound around the read of the machine. RIGHT after it happens, the motor keeps turning but the filament stops feeding. There is no issue with the motor, and the screw is tightened plenty.

I can manually turn the gear and it moves the filament back and forth with no issue. The prints are fine for the first 3-4 layers then thats when the pop happens and it stops feeding filament.

I have a new nozzle too, works just fine. The machine is a UM1, with the V2 extruder.

Filament: PLA 2.85mm

temp: 220

speed: 100%

-

I'm guessing you are in USA by your ip address. Please update your prefernces/location to specify a country. But assuming USA I recommend printbl.com although be warned that their filament spools won't fit on the back of the UM so you will need to build your own (out of wood or knex or something).

printbl makes very good quality filament.

Measure that filament EXACTLY. If it gets to 3.01mm then it won't work. As long as it stays at 3.00 and below you might be fine. Be aware that after going through the feeder it gets squished into an oval somewhat.

Do you have a um original or um2?

UPDATE: I swapped back to some filament I originally had from Proto Paradigm.. All the issues went away!!!

Looks like im going to be returning this PLA I got from Amazon, and I just bought 2 new spools from PP. :mrgreen:

-

Would doing a 1.75mm conversion, and having access to better quality filament solve this? I just need to change over the Bowden tube correct? Or do I have to swap the head aswell?

-

If you have a highly variable filament diameter, then there's a good chance that in some places it is getting thick enough to get stuck in the Bowden tube, which can certainly cause massive under-extrusion like this.

OK, would you consider .15mm a big variation?? I bought this off amazon, seemed like some people had good luck with it and some others dint. Where should I be buying filament from? Im tired of dealing with problems like this..

-

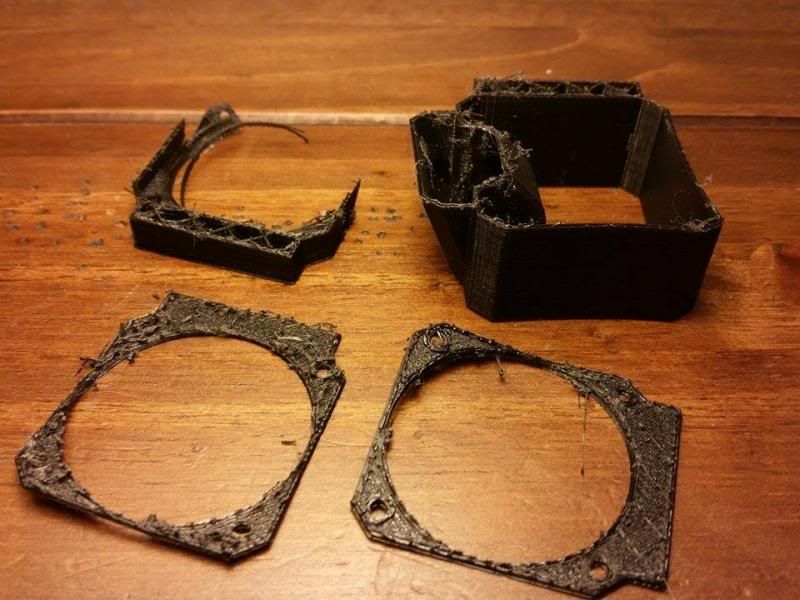

I recently switched over to a new filament. It worked well for a few prints and im not sure if the new filament is the problem? Here is the problem im having:

The order is set counter clockwise. Top right was the first time having the issue, and as you can see the problem is getting worse and now I can only go a few layer before it starts doing it.

Additional info:

Filament thickness: ( PLA Black )2.85-3.00mm

Temp: 224

-

I just bought my first 3d printer and it happened to be an original Ultimaker! This thing is AWESOME! I and have been printing a lot! I've been doing some reading and I see theres an argument about cooling and not cooling the stepper motors. I wanted, as a project to add four 40mm fans (1 fan to each stepper motor).

Can I tap into existing power form the ultimaker? Or should I be adding an additional power supply?

Also, I wanted to add some led lights so I can see whats going on since my room is generally dark.

Any advice would be appreciated! Thanks!

Any plugins to synchronize two computers with Cura?

in UltiMaker Cura

Posted

Thanks for the input, I will look into it tomorrow after work.