-

Posts

18 -

Joined

-

Last visited

Content Type

Forums

Events

3D Prints

Posts posted by h2befjon

-

-

what kind and size of Teflon tube did you use, do you have a link?

-

BUMP. I know this is an old thread but I'm curious to know if there's been any movement on getting the s5 to print using 1.75 filaments. It seems to me that a lot of filament manufacturers are moving away from the 2.85/3mm, especially those that create specialty filaments. Is this something UM would consider selling a conversion kit considering their other series prints with 1.75mm, or should I look into selling it and getting something else? I really love the Ultimaker brand but I also feel like the last couple of years it's been lacking in innovation.

-

1

1

-

-

Hello,

I have a ultimaker 2+, I'm using the supplied 4gb micro SD card and cura 4.4.0. I have plenty of space in my SD card and I'm not sure what is causing the error.

Also, I updated the ultimaker 2 + firmware through the cura app but I can't find any information on what the update was for.

Can someone help me with this issue?

-

-

Hello,

I have an ultimaker 2 and I did the + upgrade about a few weeks before the launch of the ultimaker 3. I haven't had any major issues since doing the upgrade except for the occasional print head rubbing against the side of the wall when returning home. I tried to fix that by bending the metal tab for the sensor a little forward and it seems to temporarily fix the issue. However, I don't think this issue is related to the issue I'm currently facing with leveling my bed after putting a .15 nozzle. I have tried many times to level the bed but I can't seem to an even layer, I tried adjusting the middle and front screws through the walkthrough and by starting the print. I had some "success" doing the adjustment live but when I abort and reprint the object it does the same thing. I'm using the old cura version 15.04.2 because the new version of cura 2.3.1 doesn't have the option for .15 nozzle and I can't seem to find how to manually input it. Can someone assist me? I haven't had this issue with any other of my bigger nozzles.

-

Hello,

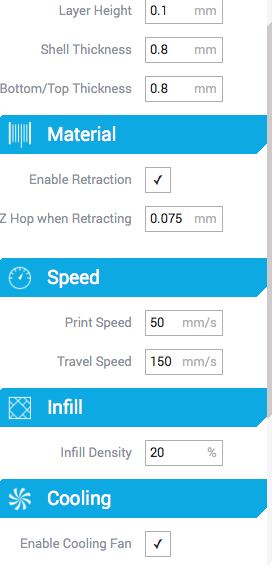

I designed on fusion 360 something to hold my shaving stuff and decided to print it in two parts.

these are the settings I'm using in cura:

I printed the first part and this is how it came out:

What am I doing wrong? I don't seem to have an issue when I print other objects from lets say on thingiverse.

-

when you slice, cura tells you exactly how much filament it will be using. It's also at the top of the generated gcode file in a comment.

Is the filament breaking because it is brittle (if so it may break inside the bowden also at the top of the curve) or because it is grinding to dust at the feeder and falling out?

I believe the filament is brittle because when I looked at the end of of the filament on the roll it has a "clean" break

-

Hi all,

First of all, very sorry to hear about these problems. You'd help us greatly in figuring out what the cause is by answering the following:

1 - What UM number is on the spool label?

2 - What batch number is on the small sticker?

3 - What settings are you using to print?

4 - What problems are you encountering?

on the lable

UM-9080-A

On the small sticker

UM-7021B075

150721A01 347

I leave the printer on while I'm at work and when I come back the filament is broken at the feeder. it has happened to me twice.

-

I gave you a roll of black with carbon - remember?

IDK if that's going to be enough, the problem is I leave the printer on while I'm at work and the two things I tried printing both are big pieces so I don't really know how to check for how long it take for it to print or how much of it does it go through before it does.

-

There has been quite a few reports of people with a bad roll of UM silver PLA recently. I also had a bad roll. It prints really bad and really hard to get a nice print, the other problem is it breaking in the bowden tube or at the feeder.

You could try a different roll and see how it goes.

Yup my roll is UM brand but I got it from dynamism. I don't have any other kind of large roll of PLA. the other problem is I'm leaving the printer to print while I'm at work so I don't know how much it goes through before it breaks and the prints that I've been trying are a bit big.

-

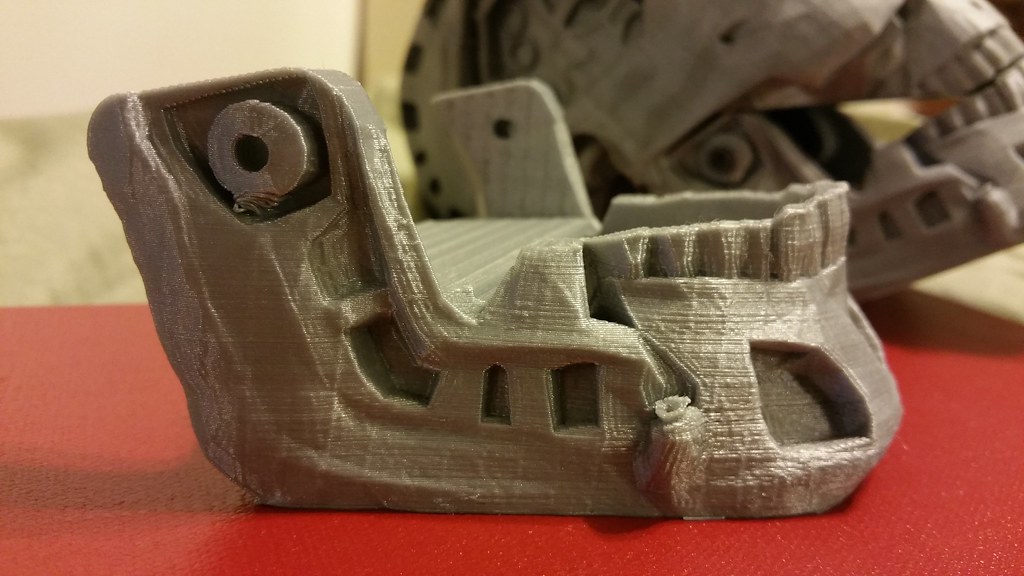

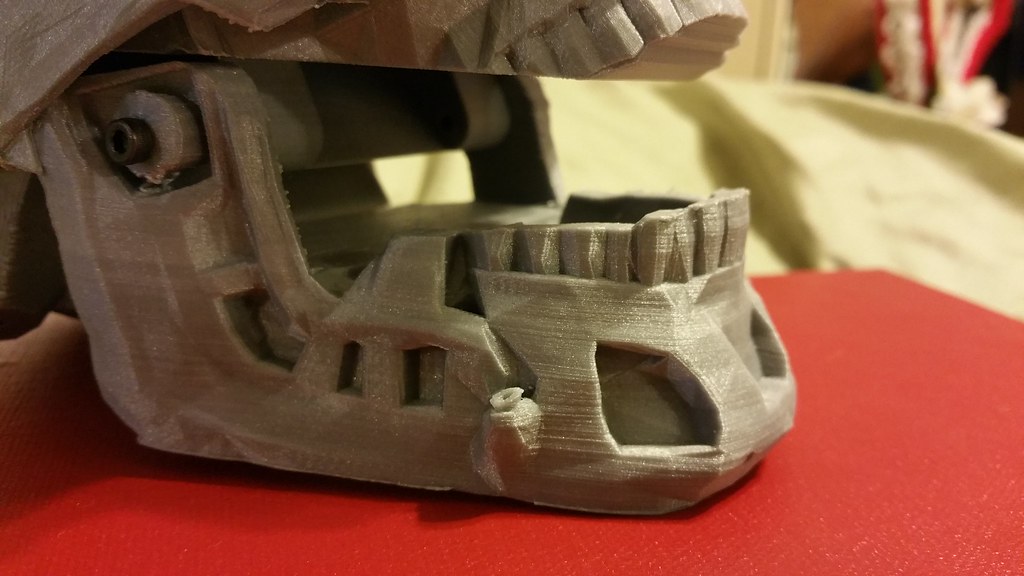

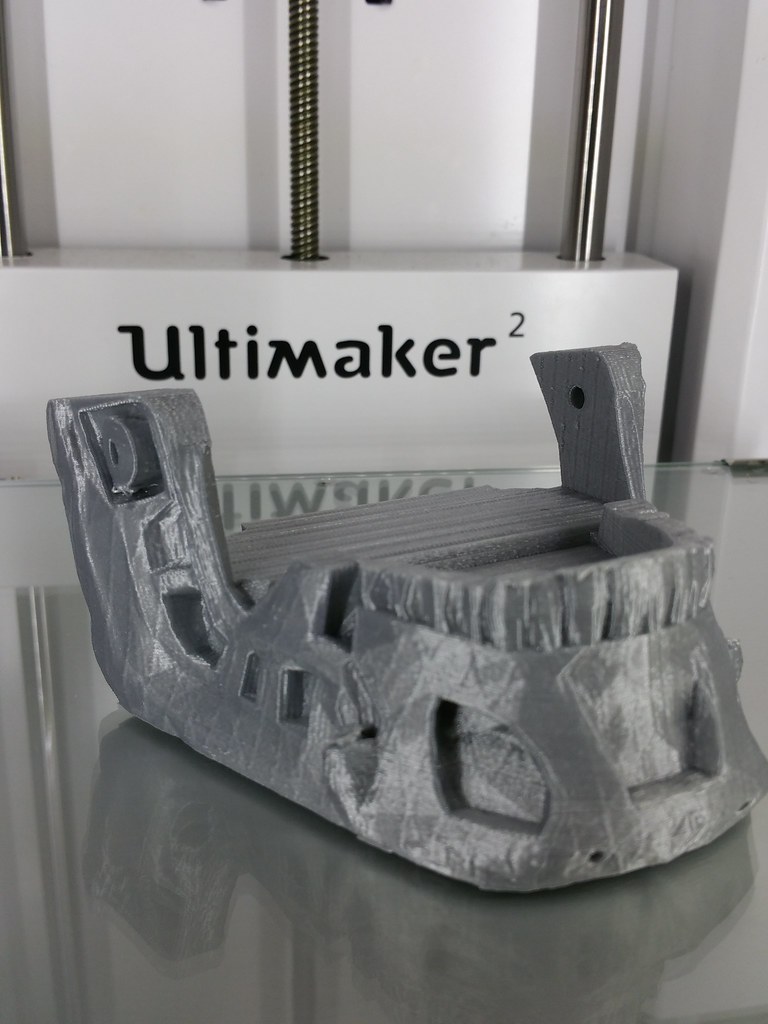

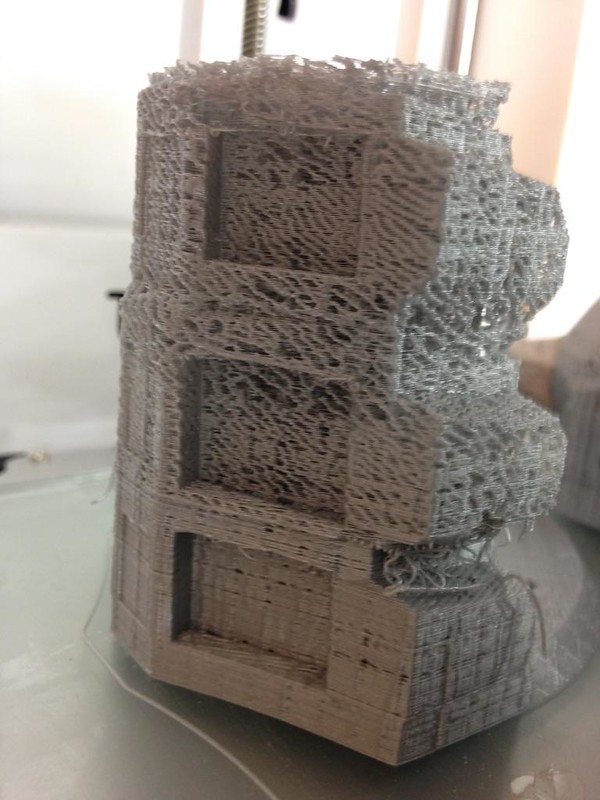

Ok so updates I think I got the situation fixed I with the help what was said here and gr5 I got the printer working better. here is the progress I've had with it.

1st

2nd

3rd

However! now I'm having troubles with the filament there's two occasions where I left the printer running and came back to a "finished" print that was incomplete because the filament had broken at the feeder

-

Has anyone else had this issue when printing duplicate or multiple prints?

You keep describing underextrusion which although it has about 40 possible causes (10 listed above) none of the causes I know about have anything to do with printing multiple prints. Did you check any of the 10 things above out? Like printing slower? The bottom layer prints slower so that might be why it comes out without as much underextrusion. Please re-read the very first answer to your original post. Above - up at the top. The one with the listing of causes for underextrusion which are numbered. As far as I can tell you didn't test out a single one of those 10 possible causes - when you do start experimenting there are more causes but don't give up before you start! Usually I can diagnose the cause pretty quickly.

I did mess with the speed on the printer itself and a slower speed did seem to help a little with the multiple print but after awhile it started underextruding again and I stopped the print.

-

Personally i just think hes got a blocked nozzle. Dude, just do some atomic pulls before each print and you should be fine. And print slower if you want the surface to be better quality.

I tried the filament on the floor thing btw........never again. In a million years. Unless you are sitting with it throughout. Unless you want to spend hours cleaning out your burn nozzle that is. Iroberts feeder and a pipecleaner to clear the dust of the filament going in sounds much better. If your gonna print off the roll do it like this.

It's not the nozzle I already tried the atomic method everything is clean, I used move material and the pla oozes out beautifully and even switched the ptfe coupler.

-

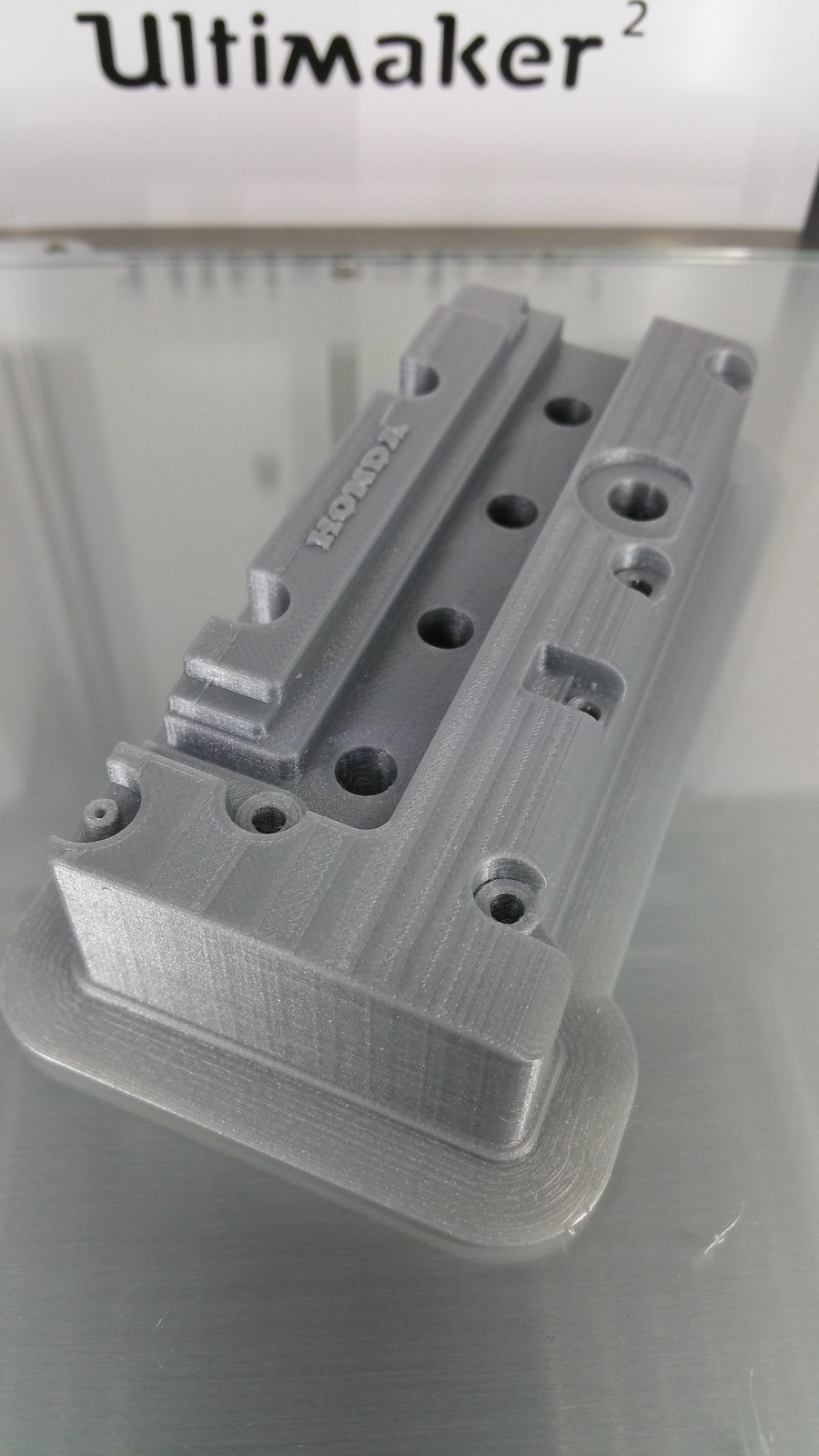

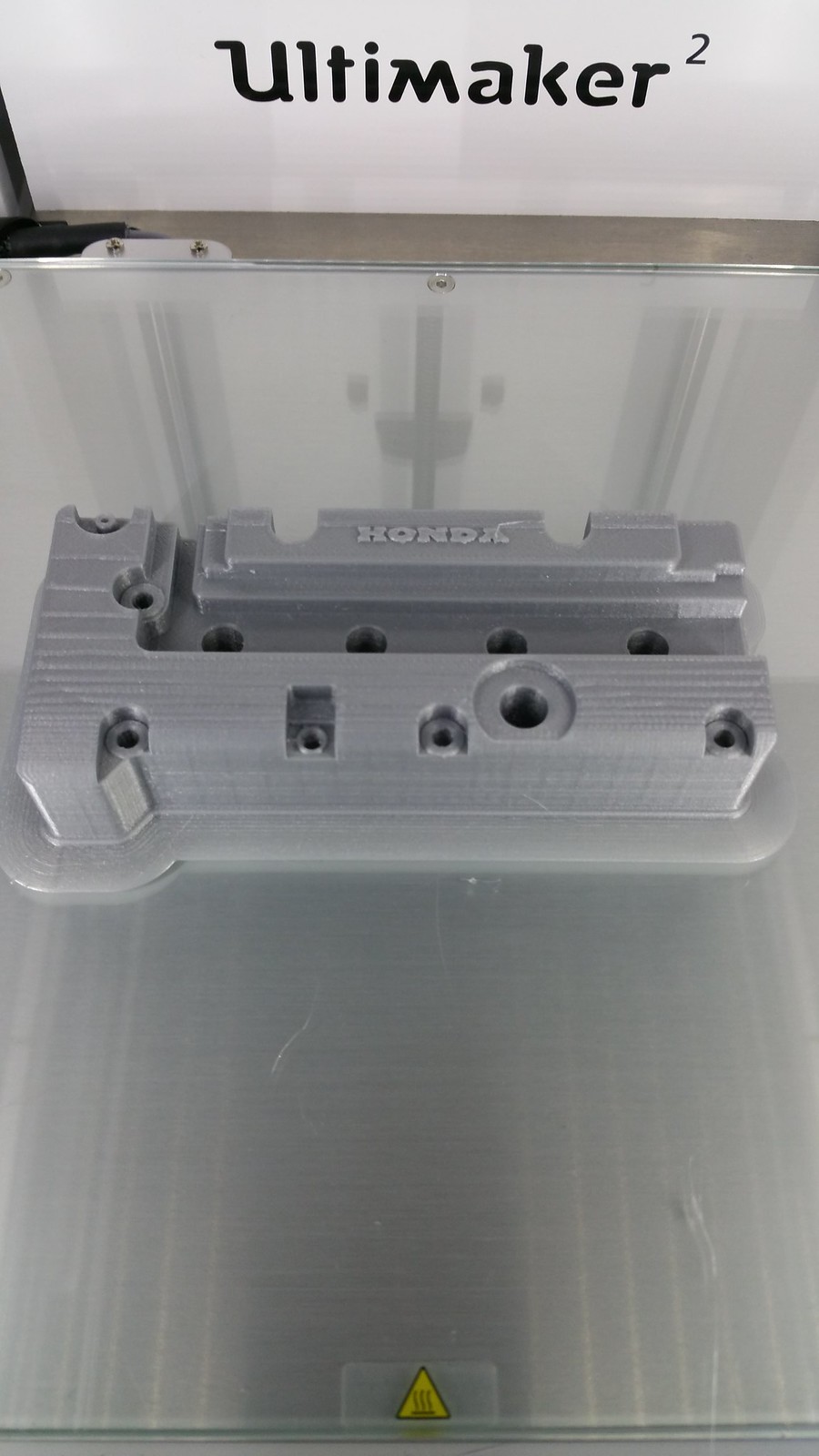

I just want to say thank you all for trying to help me out I really appreciate it. Now, I don't why the Honda valve cover is not printing smoothly I tried messing with the angles and setting in cura and it did nothing, I give up. I have yet to reprint the terminator jaw because I'm printing these Honda valve covers however, I'm running into the same issue I had on the first post, under extrusion. When I go on cura to duplicate the valve cover and then set it to print everything seems to print normal however once it starts on adding on layers there's little pla coming out. I was able to mess with the speed on the machine and set it to a slower pace and that seemed to work but I ended up canceling the print and just printing singles.

Has anyone else had this issue when printing duplicate or multiple prints?

-

maybe you can see it better on this print....

you can see vertical lines, the surface isn't smooth, ect..

-

ok thank you for the advice I did the test and stuff suggested got it to print better but now im getting this.....

these are the settings I'm using.

any suggestions on how to fix this or what could be causing it?

-

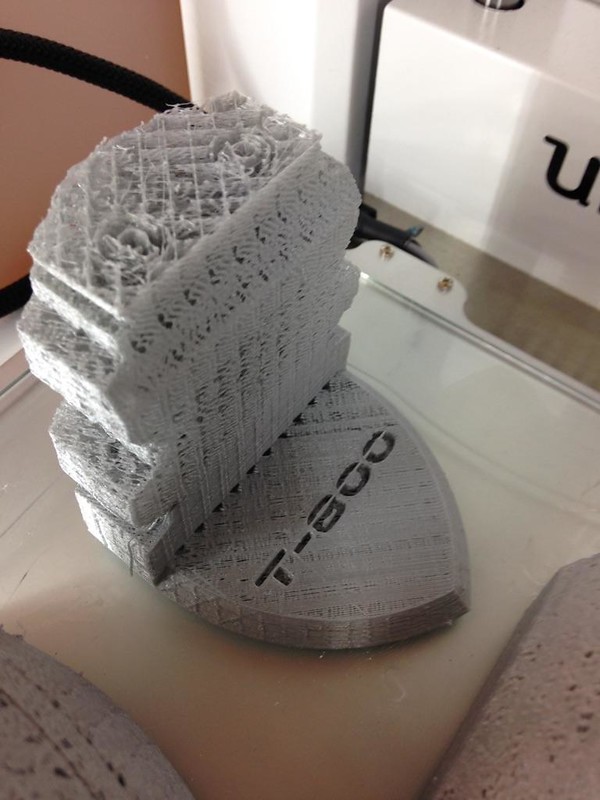

Hello! I am new to the 3d printing seen and I just received my Ultimaker 2 about a week ago. I did everything necessary and accordingly to calibrate the bed and I have done some research understanding how different options can affect a print. Well over the past 30+hrs I had set to print a t800 skull heres the link (http://www.thingiverse.com/thing:548335) the job started to look good however as the layers got higher the fill and quality of the print degraded, I noticed this with smaller objects I printed also. I dont understand why it is doing this can anybody help me?

I used pla filament that came with the unit

settings were

.2mm layer height

.4mm shell thickness

60 heated bed

210 headed nozzle

Also has anybody experienced their prints "finishing" without the print actually being finished? When I came home from work I was expecting a finished piece not a finished partial piece....

here are some pictures:

Ultimaker S5 CC Print Core

in UltiMaker 3D printers

Posted

Hello, I have a 0.6mm CC print core I would like to use with ABS or other material but I get an error on Cura stating that this configuration is not supported. How can I bypass this on advanced settings?

I'm trying to print some large abs items fast and this is the only nozzle I own to make that happen.

Thanks in advance for the help.