area0404

-

Posts

47 -

Joined

-

Last visited

Content Type

Forums

Events

3D Prints

Posts posted by area0404

-

-

And your setting differs on various micro level as well. On a cold day I usually turn up my head temperature by a few degrees so I won't suffer random under-extrusion attacks. Even different colours of the same material from the same brand may result in a +-5 degree difference. Same material from different brands may cause an even bigger +-20 degree difference.

-

Actually, I always thought a vast majority of length measurement tools come in both metric and imperial... And I just realized that my caliper doesn't. Ha!

-

Personal experience of solving under extrusion is always to increase temperature. Though I am currently upping the flow% as well while I try to somehow compensate for air bubbles in my filament. Highly doubt it will work though.

-

Only if Ultimaker is putting me on their payroll.

It's not rocket science. Perhaps they'll spring for an intern.

Apparently it is...

http://en.wikipedia.org/wiki/Mars_Climate_Orbiter

:???:

Wrote a long section about the probably reason for not supporting inches. But it seems that people before me has already answered it more than good enough. So I shall not repeat myself.

-

Interesting. Why does my machine allow me to set 60 though...? Doesn't seem to have problem retracting either. I guess that means it is capped at 45 even though it displays 60?

-

Mine limits to 60 if I do it on my Ultimaker 2 itself. Maybe it is a firmware issue? You can try updating. On Cura however, there is no warning (like when u set your shell thickness to be different from your print head width multiplier or when u put the temperature really high). So I am not sure exactly how high I can go there. I would assume 60 is the limit though.

-

Hi! Just trying to gather the masses' opinion on your retraction setting for PLA on your machine. I've faced some pretty severe stringing issues for a while now. Having dropped temperature low enough to cause delamination between layers (175 for Ultimaker PLA Black), I conducted some testing and realized that low temperature isn't likely to be the solution here. In desperation, I started tuning up my retraction distance and find that may have generated better results.

So far, I find the most effective being 60mm/s and 9mm. Personally, I heard ppl having their optimal result at much lower (like 60mm/s and 5.5mm). Is that something differs from machine to machine? Or perhaps we have yet to discover the optimal setting?

Please answer to this poll so we can find out!

-

I do. And the z-axis is definitely loud. But a closed door seems to do the trick. Don't think I'll fiddle with the internal electronics yet. Hahahahahaha!

-

One thing I don't understand. Why must the exit of the fan duct be always stretched over the entire block instead of just focused on the nozzle itself?

-

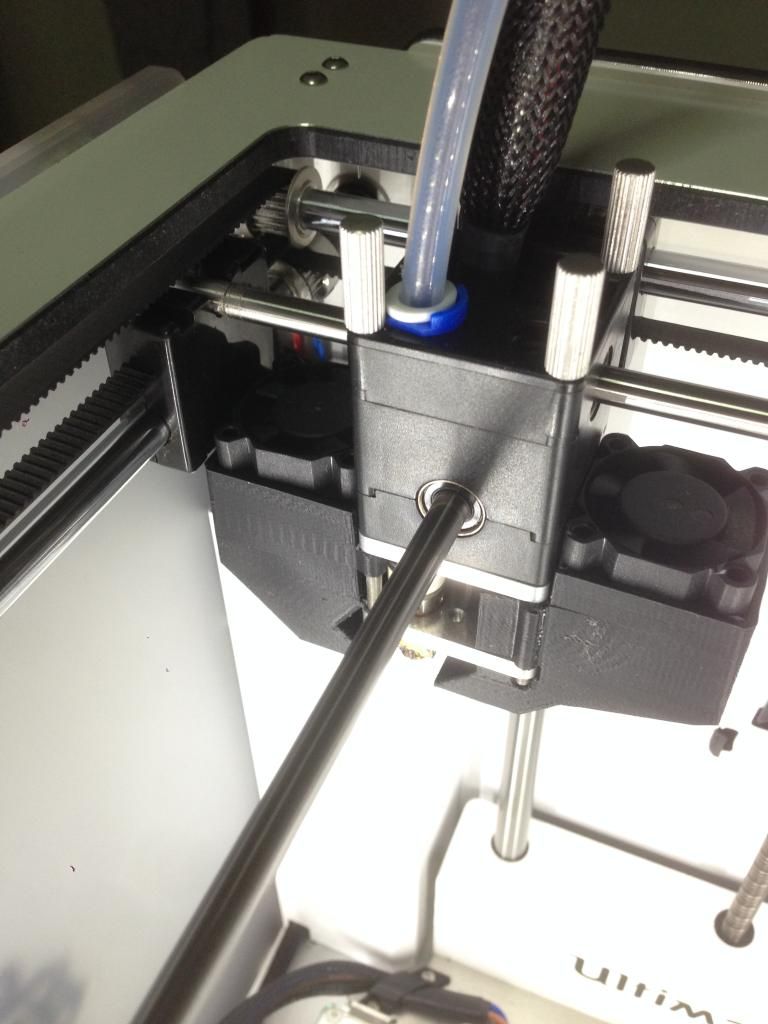

Hm... Strange. I followed the installation guide and the shroud and fan would definitely have hit the sliderblock. Not too sure if it is due to a misintallation. However, every other part seems to be in the right position. This is about 1cm away from endstop.

-

And this is precisely the reason I am constructing myself a encasement + carbon, hepa dual filtration system. Started worrying the moment I started printing with ABS.

-

Just while we are at it, it has issue exporting onto SD card as well. No problem saving the gcode onto desk top then copy the file to SD though.

-

It seems that the plugin "Tweak At Z 4.0" is not working at all here.

-

Simple as stated. 15.01 Cura does not save the settings for plugins even if I export settings. Pretty sure it is not the issue on my end.

-

0.1, 190,60 still has the exact same issue. Visually unable to tell the difference from previous prints of higher temp. Maybe slight improvements.

-

nallath maybe you can tell this to the sales team so they stop shipping the printer with that material?

Agreed. Makes a REALLY bad first impression on hindsight. Especially if I've used other printers before.

-

The blue material that we sell sucks. It's one of the worst printing materials that we have. I'm pretty sure a big part of the problems are caused by this. The silver/grey material prints way better.

Hooray! I was hoping for this answer! That means once I am through with this set of blue @#$@, it may be that I can do without cleaning up after every print. In the mean time, 0.075, 195 and 60 still shows no sign of improvement.

-

As a test try .1 mm and 190 degrees and 60 bed temp.

Okay. Currently printing .075, 195 and 60. Will try that setting once this one is done.

-

Problem persists at 200 hot end, 60 bed, 30mm/sec. Ah... This is getting somewhat annoying...

-

Higher quality fillament could be it.

Nope, this is the original ultimaker's blue PLA. I suppose they have a higher quality (as they are about 50% more expensive than 3rd party brands in general here)?

At that speed and layer size you should be able to print at lower temp. 200C or even lower

Hm... I'll try 200 once at 40mm/sec and see if anything changes. Thank you!

-

I've not experienced this before and only read about it. The right course of action is to flip your glass and continue using the smooth side or getting a new piece of glass altogether. Sometimes, the print is etched into the micro fracture of the glass and then during cooling (when your piece "pops" off the glass), the bond strength between your piece and your glass became higher than the bond strength between different areas of your glass and the glass pops off instead. Seems like a rather unavoidable part about printing on glass. I wonder if anyone has any permanent solution.

-

Didn't read through every post since some are really long. Here are some of my personal experience. Since I usually print overnight, I realized than the banding issue at night is quite a bit worse than during day. Though after I laser cut and installed an acrylic door (nothing on top, yet), almost all banding issues disappeared.

Perhaps, it is cause by wind creating variation in temperature. This temperature causes inconsistent shrinkage of plastic after printing. Or maybe even inconsistent extrusions.

Another possible explanation is that the door actually slows down the speed of convection of hot air so it created an ambience of slightly higher temperature which allows less and more consistent shrinkage of plastic.

Maybe you can try adding a door and eventually a top. Maybe even a heated chamber.

-

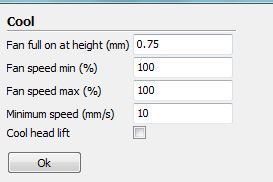

I've constantly encountered rather bad oozing & stringing issues for quite a while already. They are not hard to clean manually but as I constantly wonder if alternate solution is possible. I've tried extrusion, zhop, faster movement speed to little to no effect. I am at a lost...

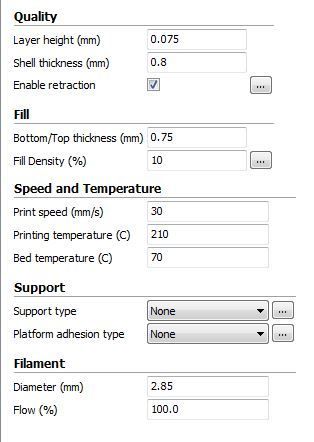

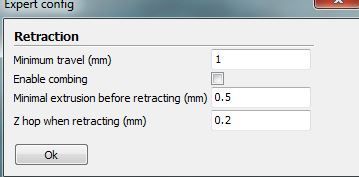

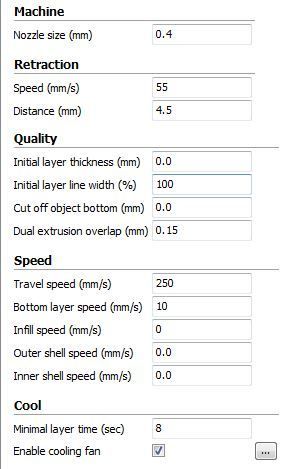

And here are my settings. Code flavor is reprap because I prefer setting temperature in program rather than manual it at printer.

Anyone knows a possible solution? Thanks in advance!

-

Never considered this before. Now I am paranoid... Hahahahahaha! Still trust my printer!

Inconsistent Z-axis homing on ultimaker 2+

in UltiMaker Cura

Posted

As stated in the title. Every print, my bed shifted up/down 0.2-0.5mm, requiring aggressive releveling of bed during skirt (fortunately so far it has been within adjustable range of the bed leveling screws). My machine has been more than 5 years old, originally a Ultimaker 2 which is upgraded to 2+. The motherboard burned itself out some years ago too so that was changed to a new original board.

I'm wondering if I'm just dealing with an old homing limit switch or if this is a software issue.