dbrgn

-

Posts

17 -

Joined

-

Last visited

Content Type

Forums

Events

3D Prints

Posts posted by dbrgn

-

-

I can confirm that in our case replacing U6 and D16 helped! The UM2+ is again printing happily, for the cost of about 2$ of spare parts 🙂 Already has almost 5000 printing hours.

In order to replace the parts, you'll probably need a hot-air rework station, solder paste, flux and maybe a desoldering station (vacuum pump) for cleaning the pads after desoldering. I ended up both desoldering and desoldering the IC with the hot-air rework station.

-

6 hours ago, Alexjwb123 said:

Hi, I had same issue. Got it repaired and the same component died again.

@Alexjwb123 did you also replace the diode D16, or only U6?

-

Here's another thread with the same issue (U6 burned out):

-

Diode D16 was also broken, as @Torgeir suggested. Will replace U6 and D16, let's hope this will work.

I found a few "classic bugs" on the PCB... Could they sufficiently conduct to kill the regulator? I assume a component failure is more likely...

-

Same problem here... UM2+ is about 6 years old.

@Riboflavin did you solve your issue? The chip would be easy to replace, but if it's just a symptom and not the cause, we should find the cause first...

-

Are there signatures available for the AppImage download of Cura? After all, we're simply downloading and executing a binary on our computers...

-

For the people coming here from Google: https://ultimaker.com/en/resources/20982-custom-materials-ultimaker2-plus

-

I upgraded my UM2 to an UM2+ yesterday and upgraded the firmware using the current beta.

Now it appears that when changing materials, the heat bed is also heated. That extends the time it takes to change filament by several minutes.

Is that really the case? If yes, why?

Also, the progressbar does not seem to work properly in the "change material" dialog.

-

Yeah, awesome! Many thanks to the jury

-

1

1

-

-

Small addendum: We noticed that the fork handle also fits the big spoons in the same IKEA cuttlery set

I should have posted my entry at 16:58, I'm sure it would have done the same effect, wouldn't it?

I should have posted my entry at 16:58, I'm sure it would have done the same effect, wouldn't it?

That wasn't on purpose at all, I barely managed to finish printing all the prototypes

-

1

1

-

-

(Here's my entry, just in time!)

My wife occasionally has problems with her joints. When they hurt and are swollen, she can barely hold a fork in her hand.

There are "orthopedic" forks with thicker handles that can be bought, but they're usually expensive and/or ugly. We wanted something that would benefit everyone by making a 3D-printable handle for widely used (and easily available) IKEA forks.

Goals:

- modify / improve a fork so that it can be used by people with joint problems

- it needs an "angled" surface, so that it's easier to grip

- it should fit a regular IKEA Dragon fork

- it should be removable, so that the forks can be washed in a regular dishwasher

- it should be easy to print without support material

I designed the fork in OpenSCAD so that the parameters could be customized if someone wants a thicker handle or has a different fork. The source code can be found here, licensed as CC BY-SA so that others can profit too.

Here's the result:

The Ultimaker 2 prints the 0.1mm layer version in about 6.5 hours without any support and the quality is fantastic!

For increased stability, the two parts are connected using horizontal "cross-beams". But because 90° overhangs are hard to print, we designed the beams at a 45° angle. Finally, the two sides are held together with two rubber bands.

Here's how you put the two parts together:

And here are some of the prototypes:

And finally, here's the 3D print card:

(By the way, should this entry win, then the extrusion upgrade would benefit our local hackerspace, where the Ultimaker 2 is being used for many hours every week.)

-

1

1

- modify / improve a fork so that it can be used by people with joint problems

-

Hi all

This might interest some of you. As my student research project thesis in 2013 I created a Python library for 3D design / visualization.

To quote the description from my project page:

Tangible is a Python library to convert data into tangible 3D models. It generates code for different backends like OpenSCAD or ImplicitSCAD (not yet implemented). It is inspired by projects like OpenSCAD and d3.js.The difference from Projects like SolidPython is that Tangible is a modular system with an intermediate representation of objects that is capable of generating code for different backends, not just OpenSCAD. Additionally, its main focus is not general CAD, but printable 3D visualization of data.

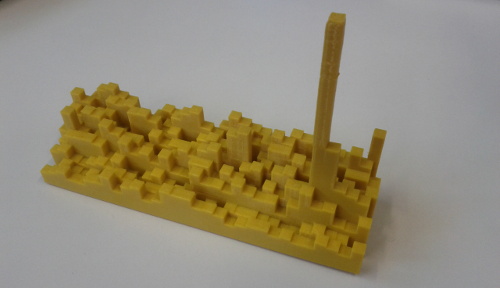

Example of a 3D visualization:

So to summarize, this library lets you easily convert data (like time series, for example) to 3D visualizations in the OpenSCAD format, that can in turn be converted to STL.

Project is here: https://github.com/dbrgn/tangible

Docs: http://tangible.readthedocs.org/

Thesis: http://eprints.hsr.ch/351/

Would be great to get some feedback!

Danilo

-

1

1

-

-

Oops, sorry. It's an Ultimaker 1 of course. The wooden one. I somehow mixed it up

Thanks for the help.

-

I simply downgraded to an older version. 13.06.5 seems to work fine.

You might be right about the UltiGcode thing. In contrast to the older version, in the newer version this whole part is missing from the preamble:

G21 ;metric values

G90 ;absolute positioning

M107 ;start with the fan off

G28 X0 Y0 ;move X/Y to min endstops

G28 Z0 ;move Z to min endstops

G1 Z15.0 F9000 ;move the platform down 15mm

G92 E0 ;zero the extruded length

G1 F200 E3 ;extrude 3mm of feed stock

G92 E0 ;zero the extruded length again

G1 F9000

M117 Printing...I last upgraded the firmware about half a year ago. I guess I'll have to do that again, to be compatible with the newer version...

-

Since Cura 13.10, when exporting G-Code files and printing them on my Ultimaker 2 via SD Card, the files seem to be buggy. The print head immediately starts to print in mid-air, without raising the build platform and without heating the head.

The temperature shows "22/0 °C".

Here's one of the generated G-Code files, if someone wants to analyze it: http://tmp.dbrgn.ch/bearing6.gcode

I'm using Arch Linux with the package from AUR: https://aur.archlinux.org/packages/cura/ (see https://aur.archlinux.org/packages/cu/cura/PKGBUILD)

Board failure - U6 chip burned out. Any tips?

in UltiMaker 3D printers

Posted · Edited by dbrgn

Here's a blogpost with a summary of the repair: https://www.coredump.ch/2020/08/25/ultimaker-2-repair/