-

Posts

34 -

Joined

-

Last visited

Content Type

Forums

Events

3D Prints

Posts posted by obus3d

-

-

On 1/26/2019 at 7:02 PM, ahoeben said:

Did you change the Gcode flavor to "Marlin" in the Machine Settings?

No I haven't changed anything.

-

I have the same issue, running the latest Cura 3.6.0, and upgraded FW on my UM 2 Extended. My SD card slot seems to be damaged so can write the code on SD and now I can't print via USB as well...😂😂😂

Please help!

-

Please help me!

When homed manually and start printing, everything works fine, after printing the head moves left but not back.

When I try to home from the menu the head actually move short steps forward.

When pausing and continuing it resumes printing on completely wrong coordinates.

How on earth did this happen? Does anyone know how to solve this?

-

Thank you all, I think the issue is solved however I have a new one...

Suddenly the head does not return to home anymore...

This is so frustrating! My Printer has only printed less than 400 metres but I have so much trouble with this machine... :angry:

-

Hin Yoter,

Thanks for your reply!

My PTFE couples was changed recently and I replace them frequently. I hav't checked it hey but I expect it to be ok.

Bowden is ok and manual material feed works ok.

I will however clean the feeder just to be sure and I haven't checked it's tension yet, I have to dig in to this.

I was already planning to print a spool holder because especially the large spools do not work great on the standard spool holder. But first I need that thing to work again...

I've had problems with other filaments as well, the best result I can achieve now is with regular UM PLA @ 20 mm/sec. But still the quality is not the same as it was.

The nozzle I'm using is also a new one from Maker Point, so that should be ok as well.

Thanks again for your helpful feedback!

Regards,

Mickael

I've had similar problems before (we've all been there!). Here's what I've seen in the past:

My PTFE coupler deformed over time. This is easy to check, remove the bowden and the nozzle from the head and straighten out a piece of filament, does it pass through the head with no resistance?

I have had the feeder get clogged with dust from filament on my first printer. I blow it out with canned air every week when I do my weekly checks/maintenance.

Check to make sure there are not filament strings/debris inside your bowden tube.

Check your filament diameter. You're using good stuff, but if the problem seemed to start when you started a new roll or new brand, it's always worth checking. I once had a single roll out of a batch order that was out, the other nine were great.

Check your feeder tension. There are a couple different settings and you can find the proper one for the build date of your printer with a quick search of the forums, I forget when the split was. As a rule, I power down the printer and see if I can move the filament manually with the motor de-energized without too much pressure. You want to be able to push the filament, but not crimp it so tight it is out of round/grinding.

My nuclear check for extrusion paths error if all this doesn't solve it is to start with the bowden pulled out of the head, heat the head and push filament through by hand. There shouldn't be too much resistance and you should be able to get a steady stream of filament out the nozzle. If this works, secure the bowden to the head, remove it from the feeder and repeat while pushing the filament through the bowden. This will indicate if there's friction in the bowden somewhere. Next, pass through the feeder and see if you can still feed. Basically, eliminate problem areas from the head back one by one.

Also, if you have a space you can do it, print a spool holder and feed the printer from the floor. Running a straight angle into the feeder does wonders. I use my spoolholder when I am visiting schools or taking the printer somewhere, but at the office, my printer sets on a cabinet with a hole in the top where my filament feeds from a spool holder sitting on a shelf underneath. I had seen GR5 mention before how great it was and I saw him post it again and again and it took me an embarrassingly long time to finally do it and I wish I had done it a year ago.

When printing a spool holder, don't over-think it. Lots of models out there have bearings, adjustable spacers and such. I just use one that lets the spool turn on a shaft. None of the printers I've ever run came with spool-holders with bearings, so I always figured if it made that big of a difference the manufacturers would be one of the first to adopt it. I believe this is the one I am running right now:

http://www.thingiverse.com/thing:32204

-

Hi Torgeir,

Thanks for your reply, here are my answers to your questions:

- I'm Using Colorfabb PLA/PHA

- Nozzle temp: standard @ 210 degrees but I went up to 225 and even 230 degrees, achieving slightly better results.

-Nozzle temp seems to be have normal during printing, temp only fluctuates 1-2 degrees from setting.

- Printspeed was 50 mm/sec (20 mm/sec worked a few times for smaller prints)

- Feeder doesn't grind

- Only when feeding new material, sometimes the fever slips/kicks just a little but this can't be heard during printing.

- I'm using the Olsson block with 0.4 mm nozzle.

- Feeder does not seem to find material other than normal during printing.

I hope it can be fixed soon, but I don't know where to start anymore and I'm not able to invest in all sorts new parts so I hope that I can find an "easy" way... :-)

Thanks for your help so far!

Mickael

Hi obus3d,

I'm very sorry to see this, also to hear that you've been struggling for such a long time with this problem.

This is more than "under extrusion", you have some serious error/problem here.

Looks like the skirt is OK. -and the first layer as well..

So first question, what kind of filament are you using here? And what is the temperature setting you're using for this print? Did you monitor the temperature to see that it is correct? This is a low speed print, what speed then?

Then, -during filament insert/feed and extrusion, -there is some signs that can alarm if something is wrong!

This pre feeding with the plastic extrusion out of the nozzle, is it going very fast without any kick back of the feeder? It should continiue with same speed as it started with without any slipping or feedback (assume using 0.4 mm nozzle), can you confirm this?

The question I'm ask here is "valid", -if you're using PLA. PLA is the best filament to use for measuring/testing, -this is also the one that's create less problem in general..

Does the feeder grind your filament, preventing feeding properly?

Yes, sure I'm asking a few question here, but we need some answers in order to help.

Here's many people with lot's of experience, so I'm sure your printer problems soon to be fixed.

Thanks.

Torgeir.

-

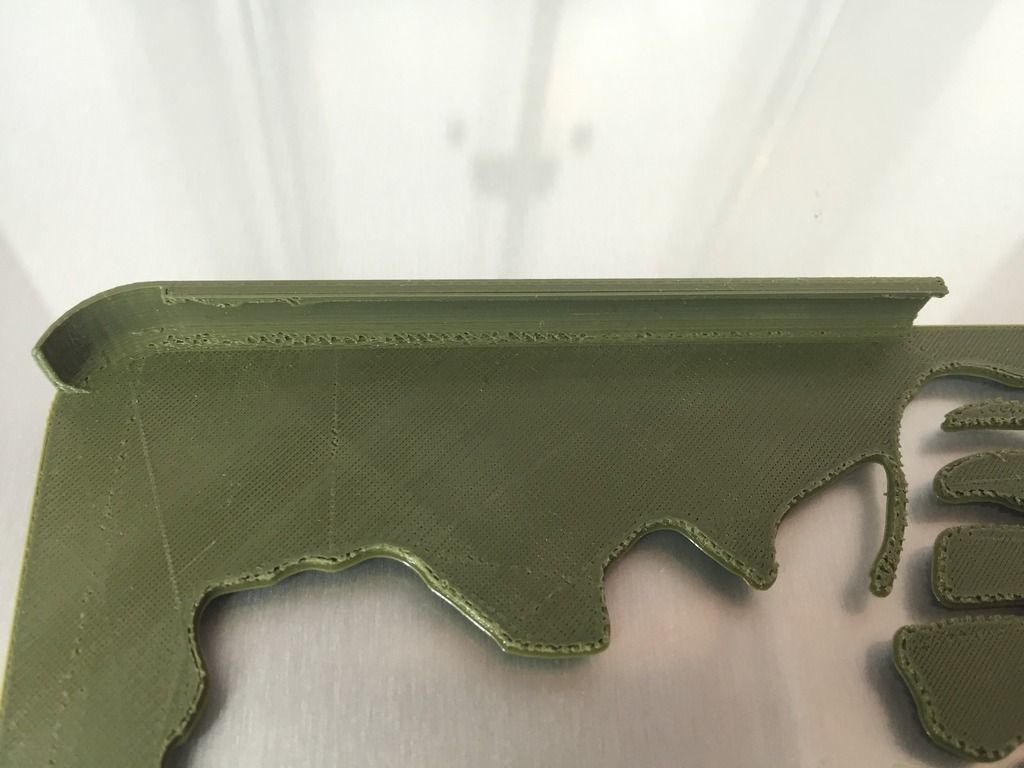

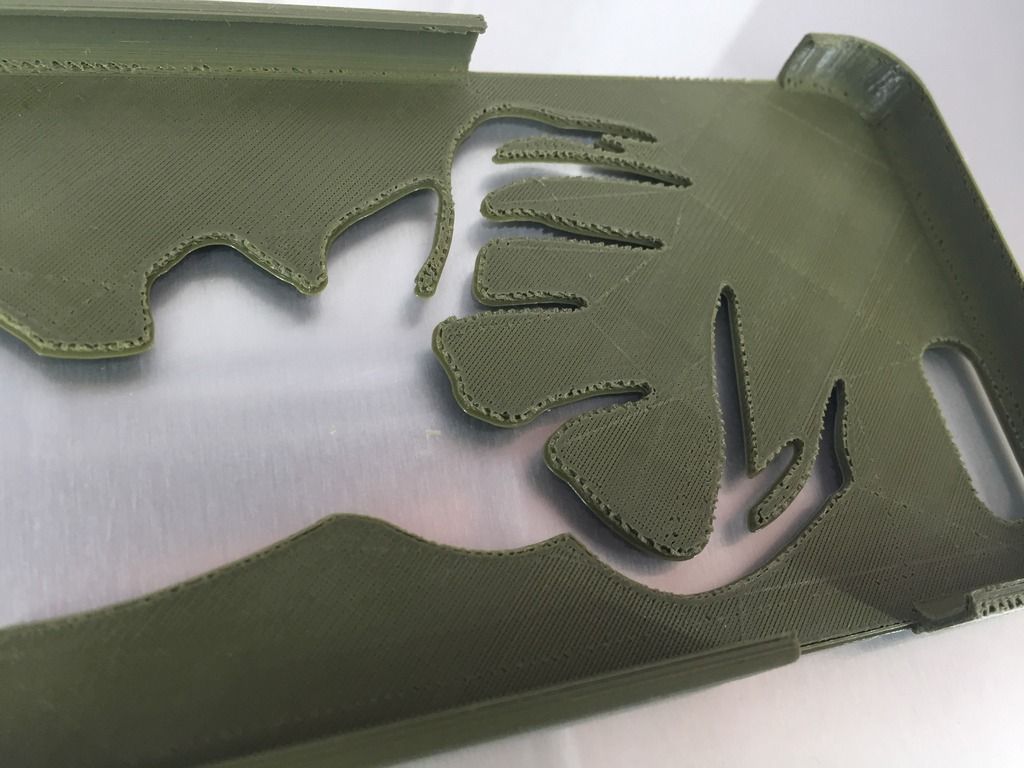

Hi there, I keep on having problems with my UM 2 Ex for the last couple of months.

I re-calibrated numerous times, switched materials, installed new nozzles, I increased heter temp, etc. etc.

I don't know what to to anymore but prints keep on failing.

It seems that when printed extremely slow the results get better but not as it should be.

Please comment, what can I do and is this under extrusion or something else? I looked online and it seems that the under extrusion issue is hard to fix and increasing flow does not work obviously.

Is it possible that the heater is defective?

-

Thank you, and yes I know them, I've ordered a few eventually but € 8,- postage for 3 nozzles and € 2,- for paypal is not not very inviting...

-

Where can I get good and affordable nozzles for my Olsson Block.

Dutch and Belgian webshops I've found so far are most of the times over priced, have noting in stock (longer or even uncertain delivery times), or they do charge ridiculously high postage costs.

I would also order in Germany if the price is right.

Anyone?

-

Take a pen draw + and finish XD

No just a joke they say first quarter this month end the quarter

Ok thanx, I hope so...

-

When will the + upgrade become available for UM2 (EXT) owners?

I really want to upgrade to the + version asap.

Thanks!

Mickael

-

How can I get this plugin to work in Cura 15.04.4 for mac?

The plunging is ignored no matter what I try but I really need to have more and better information about pricing and materials. 3DHubs seems to be off a lot...

Best regards,

Mickael

-

I used no fans at all for better fusing of layers and I also disabled retracts because it's best to have a constant flow with this material.

-

1

1

-

-

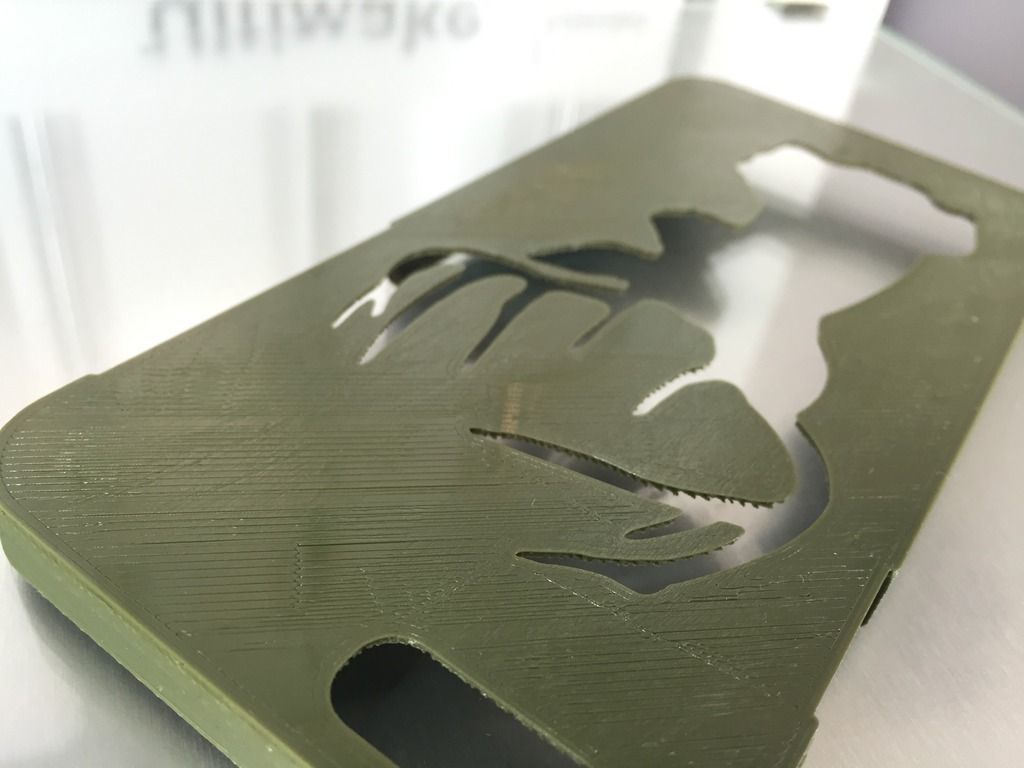

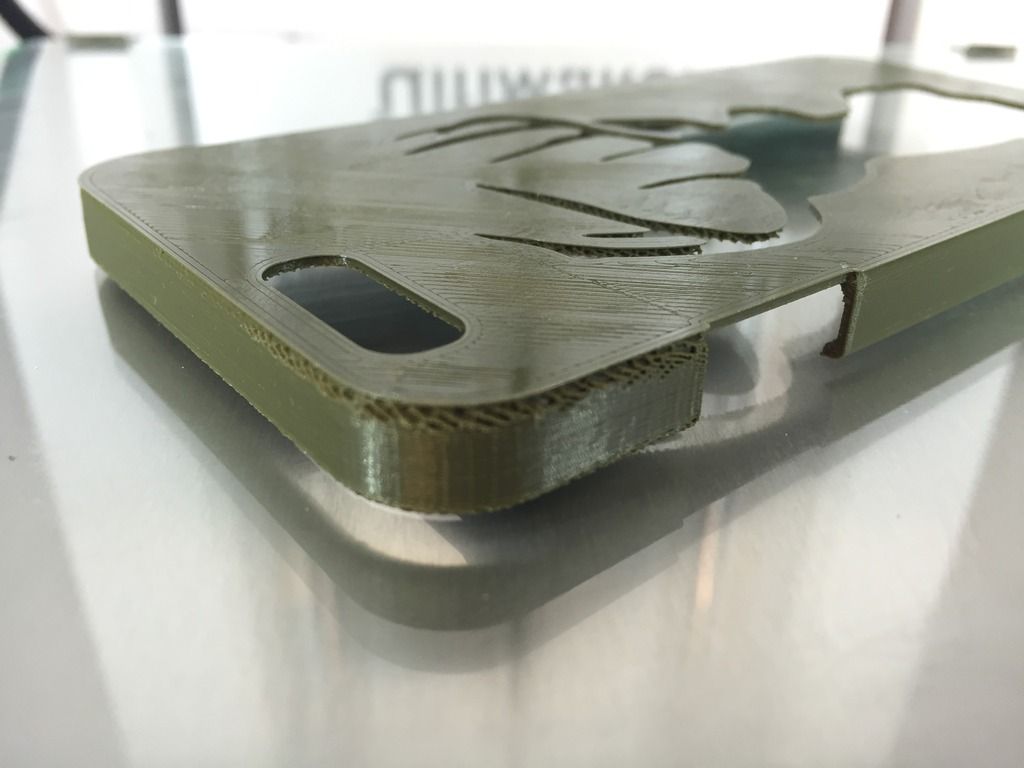

Looks ok so far, surface indicates good layer fusing, no visible layer fractures. (except for the lower left?)

But you've got a pretty big thingy going on over there...

Luckily this material can be sanded very nice and smooth

-

Yes I do, in fact I'm getting some really nice prints with some materials. but sometimes it's all messed up, haven't figured out why yet.

I was not thinking of the printer itself although I had some minor issues and also the LCD flickers since the beginning I had it but don't know if that's normal.

See:

well, you can still wreck it within the month

when you start the print, do you get a very nice ice cone shape on the front left?

it is at 8 minutes and 50 seconds

this is exactly how it should look like, a nice upside down softice that is being pushed out..

does it do the same thing for you?

-

Hi Korneel,

The printer is one month old, did not replace the PTFE coupler yet (since it's still pretty new). By hot/cold, you mean the "atomic method"? I did that once to test it out, using ABS.

-

Hey looks great!

I had the same issue with my nozzle, it looked like it took a tar bath...:(

Alright, nailed it!

Printed with "spiralize" and it is water tight. I think the "real" filament diameter really helped. Tomorrow I will try my first 10 hour print job. Fingers crossed.

But one thing still bothers me. When the print is finished, the nozzle looks like it was smeared in molten filament - one can barely recognize the shape. I guess this is unavoidable right?

-

Anyways, I'll do some more testing with this. I've also printed a little robot with this color which was a fail as well. :(

-

I've printed this at 228 degrees which is warmer than they suggest (max. 220 deg) and the speed was max. 50 mm/s, is that too fast for something like this?

-

Hardened steel is the way to go for this material. I bought it as a set including a 0,4mm nozzle from ColorFabb. I'ts not cheap but works for me so far. I don't know if printing with smaller nozzles will be possible with this material. I haven't tested it because i don't have a proper nozzle for this.

With the announcement of the Ultimaker 2+ and the improved feeder, I wonder if that will make a big difference ? Are there different nozzles that one should use for the Carbon Fiber material for best results? There's been a lot of experimentation in this thread and I am impressed!

-

1

1

-

-

I've experimented with this as well but since you need a continuous flow of material for the best result, printing supports gave me a real headache and messes up the nice finish of the material. The smaller pipe does not touch the ground (this may be hard to see in te pictures so I placed it this way to minimize surface damage and printing problems due to supports. And as the fitting of the material had to be perfect and strong inside the bigger tube I thought that this was the best way to go. In my case the print was the end result and had to have a nice finish, a perfect fit and strong. Although CF-20 has some real cons in respect to the "flexibility" of printing, I'm quite happy it eventually came out this way. However I could not make very detailed prints with this so far. Texts don't work as I had hoped, and I had to print solid (100% infill).

I love the finish of the XT CF-20 looks fantastic... one thing to add from my experience though... XT CF-20's real or integral strength comes when you orientate the print lengthways rather than printing upwards which you can actually see in your photos above. The smaller pipe which has been printed lengthways shows the stronger melded layers... whereas the larger pipe printed upwards sometimes suffers from a lack of layer adhesion in my experience.

Having said that I do splice most of my prints/designs into 2 halves and then bond them together for future injection moulding purposes rather than making the 3D print finish my priority... swings and roundabouts as they say!

-

1

1

-

-

This is ColorFabb PLA/PHA 2,85mm

-

-

Thank you!

I'll look into this and try if this solves the problem.

Ultimaker 2 Extended (+) te koop

in Buying or selling your UltiMaker

Posted · Edited by obus3d

Wegens beeindigen van de hobby biedt ik mijn complete 3D printer met onderdelen aan.

Runtime stats, zie foto. De conditie is zeer goed. Vraagprijs €1500,-

Bestaande uit:

- Ultimaker 2 Extended met Olsson Block upgrade voor verwisselbare nozzles, met heated bed, PMMA front door, en uiteraard in werkende staat

- Originele voeding

- Diverse nozles van 0.25, 0.4, 0.6, 0.8 mm waarvan sommigen van staal

- 3D Solex Block

- Diverse tools

- Diverse reserve onderdelen zoals, heater, kabelboom, bowden tube, TFM Isolator, etc etc.

- Diverse aangebroken spoelen, verschillende materialen en kleuren Color Fabb filament

- 3D Printing handboek

Uitsluitend af te halen in Leusden