-

Posts

1,821 -

Joined

-

Last visited

-

Days Won

63

Content Type

Forums

Events

3D Prints

Posts posted by foehnsturm

-

-

Hi Lars,

8 X 8 mm & 2 x 5mm? I will place you on Joergen's combined shipment. I would like to use Paypal and will send you a message when the pulleys are ready to dispatch.

Hi Daniel,

two full sets is o.k. I'm from Germany (Munich) and I'm afraid I won't make it to Erfurt. My (main job) customers have their big event, the LASER 2013 fair, at the same time.

@Alexander Baloche

Hey, good to hear from the Ultimaker team. I put you on the list. It's my conviction that there are local companies, which can provide high quality for a competitive price.

Markus

-

Thanks Joergen.

My fault, it will be M4, same as original UM (i've just edited the original post).

-

So here are the details:

Ultimaker pulleys:

- [*]20 teeth, effective circular diameter same as original pulleys

[*]dimensions: 17 mm (outer diameter) x 16.7 mm

[*]8h7 or 5h7 center bore

[*]two m4 threads with grub screws

[*]vibratory deburred

Introductory price for orders until May 6:

- [*]8x8 (8 x 8 mm): 44 € / 58 $

[*]Set of 12 (10 x 8 mm, 2 x 5 mm): 66 € / 86 $

[*]...

VAT and customs duty not included

Payment via Paypal

Suggested shipping:

DHL small parcel, insured shipping

within Europe: 4 to 10 €

USA, overseas: 22 $

Orders so far:

Dojan, Lars 86, Xeno, Joergen, illuminarti, snowygrouch, trion, fluxline, edis, (MSURunner)

Please send me a message with your detailed order, address and email.

I will place the order next week.

-

I will fix production details and the final pricing next Monday.

Switching back to one M4 thread and re-using the grub screws might be a good idea. I'm using just one screw now and tightening two screws / pulley during adjustment seems to be cumbersome. Other opinions?

Is there interest in 5 mm bore / stepper pulleys as well?

-

Up and running. Belt tension remained quite similar.

Printed a

.Outer dimensions used to be 19.7 to 19.8 mm with the standard setup. Now they are 19.9. Which makes me think that the printhead movement might respond better to the fast +0.1 mm / -0.1 mm stepping at the corners.

Markus

-

Hmm, mainly for two reasons:

I was looking for a drop-in replacement as simple as possible. And because I will get best manufacturing quality for the same price tag or less, compared to GT2, 20 teeth, 8 mm bore pulleys (of whichever quality).

Markus

-

Well, not just some machine shop but the one where I am already placing orders for several thousands € a year.

I had nothing but the original pulley and a belt. But the master craftsman and owner, who is approaching his 70s I think, is well versed and very cooperative. So he did me a favor. They make a lot of miniaturized stuff for the medical device industry and are used to deliver utmost precision.

I have no exact price tag yet. But if I will manage to place an order of at least 100 pieces, they will be less expensive as anything else, mentioned in this thread (except Chinese bulk ware). My intention was just this:

Hopefully someone will come to fill the gap.....

Markus

-

Finally they arrived.

A nearby CNC turning shop produces some thousand gas burner jets for my wok burners each year. So I asked them, if they see a way to produce tailored pulleys for a reasonable price. For this reason it had to be a one-part-pulley instead of the three-part-pulleys, which are commonly available - and fall into pieces when drilled to 8mm, as I had to learn...

Production samples arrived today.

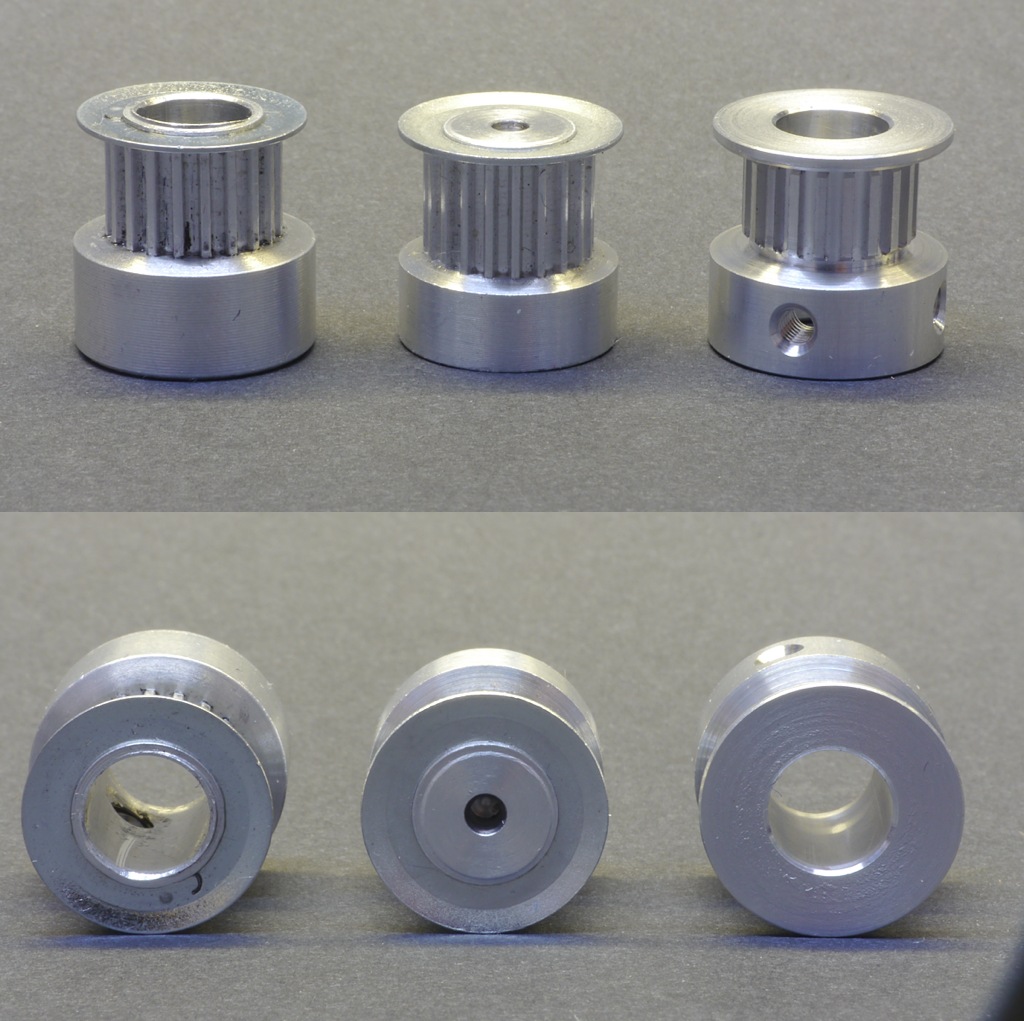

From left to right: Ulimaker pulley, standard pulley with pilot borehole, "new" pulley

Ultimaker pulley, new pulley

We tested the fitting by hand with an Ultimaker short belt, which I don't need anymore (thanks Calum). You can feel no play, whereas the original pulleys slightly move with a belt wound tightly around them.

The pulleys feature a 8h7 center bore and two M3 threads. The small gap between the cogging and the flange is a trade-off of the one-pice design. I'm not sure whether this will increase belt wearing (if so, it should be possible to design and mount some split spacers to fill the gap). But compared to the wobbling original pulleys (hey, really ugly in closeup), which even seem to feature a slightly contorted cogging, it is definitely worth a try.

I will be mounting the new pulleys the next days and keep you informed.

Markus

Fixing Pulley Innacuracy

in Third party products & modifications

Posted

Hi Zak,

this were the last 12 pulleys I had.

There is at least one other order from Australia. So we might arrange a combined shipping, as Joergen does for USA.

The entire production lot is sold out now.

If there is sufficient demand I will naturally organize a second production run.

Anyone interested please send me a message.

Markus