chrii

-

Posts

46 -

Joined

-

Last visited

Content Type

Forums

Events

3D Prints

Posts posted by chrii

-

-

Set the extruder temp to zero?

...later...

No, that would just set the temp to zero when the print starts.

Edit the gcode and remove the temp settings.

thats what i`m doing at the moment, i have to edit every gcode file, but it is annoying to do this every time

other slicers do have a the feature when setting the temperature to zero they interpret this as disable the temperatur control/command, thats why i tried it out.

You need to define your printer as using RepRap-type gcode, i.e. in the Printer Settings panel, select Gcode Flavor = Marlin/Sprinter or other non-Ultimaker type

That will expose extruder and bed temperature settings in Cura.

for sure i added my printer as "Custom FDM Printer" , and Marlin Gcode flavor, and the temperatur settings are all there, but i want to disable the control at cura at all not set it manually there.

Chri

-

Hello guy`s,

I want to use cura also on my old non UM printer.

At this printer i want to control the temperatures manual.

i disabled the "heated bed" to get rid of the control at the bed, but i haven`t found any similar option for the extruder to disable the control.

Also setting all (possible) settings to zero did not resolve my problem.

any idea how i can disable it ?

sincerly Chri

-

Two tiny questions to the (not)Mainboard, is it still 1/16 microstepping ?

And more important, decay hack activated ?

Chri

-

check out the 5-years-of-ultimaker page.

At "1016" the first picture of the electric drill, watch the Background !

will the new UM3? be black ?!?!?!

chri

chri -

any news from the Decay topic from UM side or related to the UM board ?

Chri

-

Ah thanks for that info torgeir, didn`t checked the pages before page 6

As i wanted to have it easier removeable i used the common connection point on the left (R81/R82/) and wired them to a ground point on the left side.

This is how it looked on my board

It may look as the left cable end ond R81 may shorten to the lower pin, but it doesn`t there is a air-gap in between, checked that three times before powering up the board.

Chri

-

1

1

-

-

Hy SandervG

I hope they will find a solution, the hack itself is easy in "therory", just replace a SMD resistor under every stepper to a solder bridge, so no big deal.

But unless they haven`t checked it through and gave a feedback, i don`t publish a public guide, just too dangerous atm ^^"

chri

-

Hy Torgeir, do you have a picture of your board wiring ?

To which ground point did you go ?

my problem is not solved , the two drivers are dead, so its not able to print anymore.

Chri

-

Hi SandervG,

Thank you for your post, it looks like a huge improvement in a small level of detail!

To achieve this you pulled the ROSC pin to ground? Are there any drawbacks to this?

Can't see any "main" issue, except for a little more hi frequency sound when micro stepping and (ofc) more current when micro stepping.

Thanks.

Torgeir.

Just my Expierience with the so called Decay Hack (ROSC pin to ground), that is alreaday known to the A4988 drivers since some time.

I did the hack for over a year on my other printers, with success on all steppers /printers i have.

I also discussed that issue also with valcrow since long time.

so i finally tried the decay-hack on the UM board 2.1.1 , with bad results.

(i`m skilled at soldering so no problem from this side

)

)first i did the hack on X and Y axis on the board, resulting that the X driver instantly burned after powering it up, Y axis is still okay.

after that i reconfigured E1 to be the new X axis, and printing was well with that "decay" lines also dissapearing on the Y axis, so its definitly the cause of the effect.

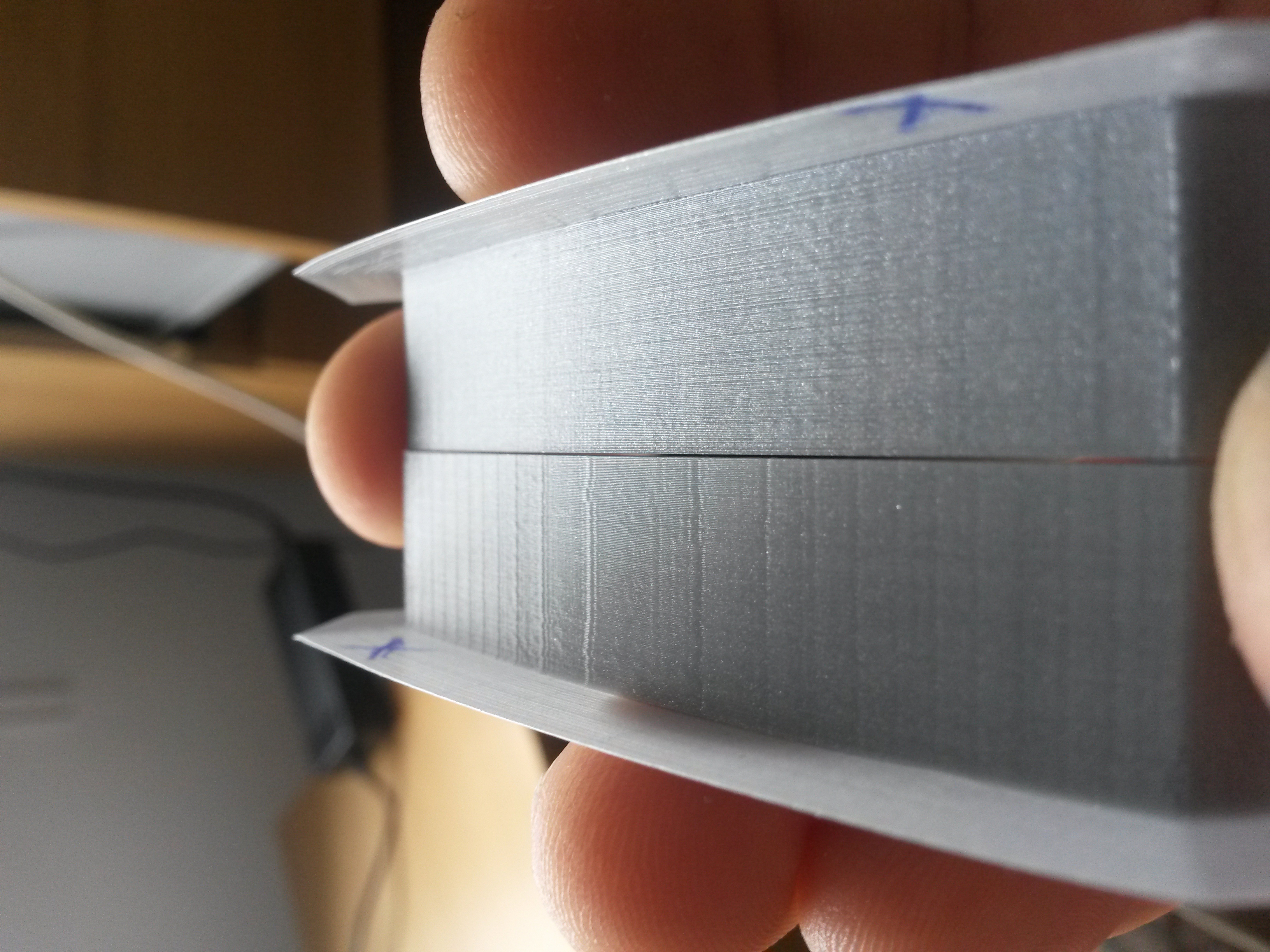

Here a picture of the comparison, before and after:

Ignore that X, its Y axis ^^

Unfortunatlye i then did the hack on the E1 driver, resulting in also a burned driver after powering up.

Normally setting ROSC to ground should not be an issue there, but maybe some UM engineers ma have a look on it why steppers altough tend to burn up when do the hack.

So far, now i have a bricked UM2 standing here :(

Chri

-

Oh, if someone is really taking care of it, a Night theme would also be cool, would be easier for the eyes at night

Chri

-

the best would be an option to select the wanted order.

for me i would prefer perimeter/shell/infill, as mechanical parts will come out more exact, for sure overhangs are more difficult but most mechanical parts have straight surfaces.

so maybe a choice between three types:

* shell/infill/perimeter

* perimeter/shell/infill

* shell/perimeter/infill

Chri

-

Hy guy`s

we are recently more and more people at the UM Chat (just hitting 10 people

) , and i wanted to ask if someone can maybe do a little upgrade to the chat dimensions, as the window size is limited horizonally ?

) , and i wanted to ask if someone can maybe do a little upgrade to the chat dimensions, as the window size is limited horizonally ?I also have always a about 165 pixel wide white space on the left side of the chat frame.

so no tragic bugs, but it would make it easier if these would be fixed

Chri

-

Just put a piece of cardboard on the surface then it will heat up faster, an no the cardbord will not start to burn !

Chri

Chri -

Sollte doch ganz easy sein.

Auf einer Seite ist A1B1A2B2, das ist der Ausgang der auch auf der Unterseite der Stepper stehen muss, der sollte an der Steckerseite vom Board sein.

Gegenüber liegen MS1/MS2/MS3, das sind klarerweise die Microstepping Jumper, also einfach die Leiterbahnen verfolgen, schon hast es raus.

Chri

-

The Go would have been a great chance to use 1.75mm filament. I know that UM wants to minimize the number of custom parts, but if the Go is a marketing machine anyway, then they should have gone through with it.

I don't like 2.85mm filament. It is "stubborn" and harder to handle. Nearly poked my eye out a few weeks ago when I switched filament... I know that 1.75mm is pricier but Ultimaker is in the best position to change that. If their printers start to adopt that filament size, there is another big argument for the thinner filament.

switching a long bowden from 3mm to 1.75 isn`t a very easy job, the 1.75 material is much more flexible so it will cause lots of pressure issues, especially when printing faster, thats why most (or all?) bowden style printers use 3mm filament.

Chri

-

* Possibility to print directly from PC (USB) mainly the reason why i haven`t bought a UM(+/2) yet.

* Multi-Extrusion (2-4)

* all PEEK Hotend (see m-p v10), please NO all-metal crap

* lower base cost (maybe a UM3-Basic in UMO style with Dibond or so?)

* a DIY KIT

* 1.75mm support (difficult with bowden i know, maybe a micro direct drive option for flexible filament (sub 100g))

* Quickrelease system for the printbed glass plate

* Heatbed with higher temp. support than 100°C

Chri

-

I already tried serval speeds,temperatures and retract and Z are already really really fast, the effect are not blob`s (too much material) they are already too less material because of the speed from retract/Z travel when not printing.

So the effect is already minimized to the minimum, as you can never get the seam complete vanished.

Therefore it would be great if it would possible to change the start/end oder either to a fixed side / a algorythm for finding a corner/ or at least always relatively the same position.

Chri

-

Hello

I`m having the same problem with cura, since i want to get rid of the very slow skeinforge after years.

Depending on the part the startpoint is "random" or alwas on the opposite side of the layer before.

here are some sample pictures:

The Squirrel has the "random" problem, the leg has the "ping-pong" effekt.

The rest of the surface is great but this spread out starts make the thing not really useable :(

is there a change that there may be a fix or a new option to avoid this will be available soon ?

the rest of Cura is great so i really want to use this software in the future.

Chri

-

-

Hy

I want to change the order of the perimeter and infill of cura and i saw that it should be possible with the cura that is on github.

I tired to get it running but without success :/

Is there a step by step guide (for dummies

) to geht it running ?

) to geht it running ?Chri

Disable temperature control at cura (2.6)

in UltiMaker Cura

Posted

Thanks for your answer, but as you mentioned it already, extrusion would be volumetric what is not enabled on my printer, so i can`t use a UM2 profile for that.

i just installed Cura 2.6.1 but haven`t found where the printer definition is stored at all to search for that "overrides" part ?

is there also no option to export a custom printer profile ?

Chri