chrii

-

Posts

46 -

Joined

-

Last visited

Content Type

Forums

Events

3D Prints

Posts posted by chrii

-

-

Hello 🙂

I`m printing with a 0.4mm Nozzle on my Orca with DD Extruder.

i``m using 0.2mm layer width for Support line width this way it is still stable enough to support the print but it is much easier to remove.

For sure 0,2mm layer widh does not stick very well to the baselayer of the printer.

Is there any reason why Support is not part of the Initial layer width ?

Would be great if this would also be added to the initial layer.

Kri

-

42 minutes ago, ahoeben said:

Did you perhaps change your material (filament) diameter to the wrong value? Check the extruder tab(s) on the Machine Settings on the Printers pane of the Preferences.

Thx, that was the issue 🙂

Another thing, is the software really so slown ? every click takes very long ?

4.3 was faster on my machine.

Chri

-

Hello guy`s

It was time to reinstall my laptop (Win10) to have a fresh start as this is sometimes a good thing.

However Cura 4.5 is driving my crazy (i come from 4.3. before which was working fine)

When i set up my Orca as "Custom" Printer, is just get no Filament profiles listet.

The Favorits and Generic list ist just empty, when i hit the create button nothing does happen.

When i add a different preset Printer like Ultimaker2 or Anet A8 and activate it, there are material profiles, but when i switch back to my "custom" printer, all Material profiles do dissapear

Also when i try to import a profile which i had created unter the Anet A8 Printer it does not show up.

What am i doing wrong ? is it a bug ? at least this is not intuitive....

Chri

-

Hy, Sanders, i like the new UI, expecially the dark mode and loading times are great 😄

i have some suggestions

* Is it possible to add antialiasing to the Preview mode ?, it has lots of miroe effect

maybe adding some "glossy" effect to the lines will help the visualisation to look better (you may check craftware 😉 )

* Is it possible to implement a function to change the colors of the directly at the "color scheme" feature.

the default colore are not very good in my eyes, i instantely wanted to click on the colored checkboxes next to the line name to change the color there 😉

* is it possible to implement also a "per line" slider, not only a per layer ?

with the Per line slider also a field of showing some of the gcodes lines would be great (you may again check craftware;) )

* loading older cura (or different slicer) gcode does not support the layerbar, the bar does only show "1" layer.

sincerely Chri

-

I just noticed that the Ultimaker 2 go is not present at the "products" page anymore.

Anyone does know why this is ?, do they plan a new version or was the product not well sold ?

Chri

-

Best ist to also delete the three spam users who are at the activity list

Chri

-

Thx for your fast support

Chri

-

-

Thank you,with machine instead of material it is working (or better said not working anymore

)

)Chri

-

@ ahoeben, i uploaded it here

Chri

-

Hy Ghostkeeper,

i`m printing on my orca, and using my own start and end gcodes, which do not have the M104 command within.

Chri

-

-

1

1

-

-

-

@ Neotko , great "soundtrack of that video

I found two different versions of the TL-Smoother, one with 4 diodes and one with 8 smaller diodes, any recommendation what is better ?

Chri

-

1

1

-

-

As i`m also switching to 1.75mm filament the same time there should not be a problem with the strengh of the stepper anyways.

Please be aware that the Ultimaker knurled wheel probably isn't the best solution for 1.75mm Filament!

Hy @cjs, can you explain a little bit more in detail why ?

Chri

-

thanks for your answers.

indeed i`m using a Roberts Feeder .

i`m not in hurry, but i also don`t want to order in china when possible.

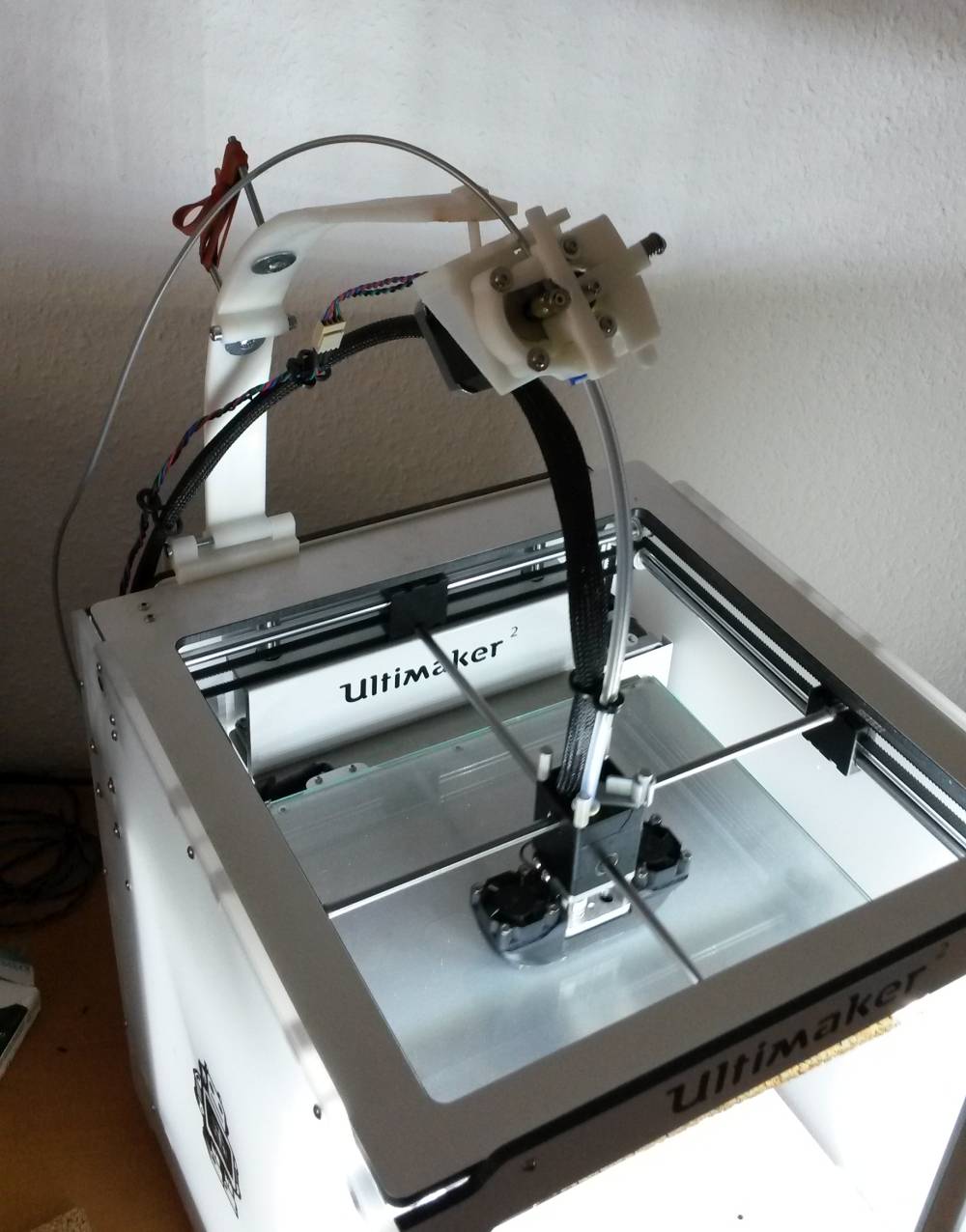

i made a short-bowden mod (20cm) on my UM2 as a preparation to upgrade it to dual extrusion. (the same setup mirrored)

the Problem is i can`t remove the wheel from my original stepper driver, its mounted too tight, therefor i just want to use the same wheel on the second extruder.

As i`m also switching to 1.75mm filament the same time there should not be a problem with the strengh of the stepper anyways.

Chri

-

Hy SandervG,

when i see the rest of the UM spare part cost, i think a new one is too expensive for me.

Chri

-

Hello guy`s,

i`m looking for a favorable used Ultimaker 2 knurled wheel.

as for sure some upgraded to a UM2+ Extruder the original wheel should ly around somewhere

preffered shipping within Germany.

sincerly

Chri

-

does someone have an idea how to disable the M104 at the end ?

Chri

-

Hello,

sorry for my late reply, i now tested a UM2+ profile including the default PLA material at the UM2 printer, and disabled your mentioned feature but the result is still the same.

Chri

-

Hi Chri,

Cure does do some quality reduction on segments smaller than 10 micron when the removed vertex would only result in a shortcut path of 5 micron. Perhaps those parameters should be set a bit more aggressive...

You could try the ABS profile from the UM2+ - it might work better than the default profile of the UM2.

I suggest you turn off the setting Fill Small Gaps for organic models like this.

Ok i`ll try that when i`m back at home next week

Maybe this would be a feature for the next cura versions to be able to manually be able to set that quality reduction distance.

This may also be used to print real "low poly" stuff as a type of art

PS: which features from Craftware (CW) would you like most in Cura?

i think you probably mean i like to see the most in cura from CW?

It`s definitely the whole viewer part,

* visualization is nice and good visible at CW which is most important, at cura its hard to see lines structure even with the new view.

* you can change the colortypes for a couple of different types (feedrate, speed, line type, material, extruder)

* it`s also calculation/showing the line width good, so every time when i try i new slicer or setting, i can check before printing if the extrusion and so on are set correctly.

* you can also go through the lines with a slider, not only the layers which is very cool

and while going through the lines it show`s you the text gcode to also can see where a issue has been generated.

altough CW has some issue with showing Ulticode some time, thats why i also tried out normal Marlin/reprap gcode.

most other things CW have had at the slicer over cura have been implemented into cura since the 2.x version, so i`m only using CW for gcode visualization/ analyzing.

Chri

Chri -

Hy

i`m using Craftware as Gcode viewer, it has some very nice features, maybe some of them will find a way into cura one day

i used the low-poly version with 28MB

i did a quick gcode check without the "compensate wall overlap" feature, was looking similay.

maybe i have time tomorrow to do a new testprint.

My systems are all with Windows 10 X64 as Cura 2.6.2 is only available X64.

On the UM2 i have the original silver UM-PLA, UM2 Settings at cura don`t show a material choice function.

on the ORCA i`m using the generic ABS feature, and configured it as always.

EDIT: what i noticed is that the gcode of UM is more than twice as large, maybe its just trying to print every detail of the part even the extreme tiny one`s

i know that other slicery normally don`t generate a gcode with that extreme fine details.

maybe a optional feature with reducey quality like minimum length per line, or a smoothing feature with a defined factor may help ?

sincerly Chri

-

Hello guys,

Most time my UM2 was printing more technical stuff and easy models without any issues.

I now also want to use my "old" Orca printer with Cura 2.6.2 as it finally has the features i need to print the quality and accuracy i need.

So the printer is working with Cura already and i printed my usual testparts with success so far.

Now i wanted to print also high res organic models, which i normally not do.

Therefor i wanted to print a little baby groot at 50% scale and there where the issue`s startet.

Both my Orca and the Ultimaker2 are equipped with a 0.4 Nozzle (Ollson Block on the UM2).

the first printed was with 0.15m layer height on the Orca and i was supprised that the print was full of pimple`s i normally do not have.

then i did a cross test and made the gcode with Slic3r and it was printed successfully

After looking for the issue for a couple of hours i have not found any issue also because simple parts do print fine.

so finally i printed the groot on my UM2 with original Low setting (also 0.15mm layer height).

But there the pimple`s also appear.

left = Orca with slic3r (forgot to set the minimum layer time, thats why whe neck is so ugly). (marlin code)

middle = Orca with Cura (marlin gcode)

right = Ultimaker with Cura (ultigcode)

After analyzing the gcode i noticed that the generated code is full with "jumped" lines.

This is the Code from Cura (marlin gcode)

This is the Code from Slic3r (marlin gcode)

At first i thought it is the stl file itself that has the issue, but then i tried a couple of other models (dragon, sculp, Elephant and most of them have the same issue.

as soon as the surface is not completely smooth the issue appears.

Afterwards i also tried Cura version 2.1.3 / 2.3.1 / 2.5 and tried a different computer with a clean installation which all gave me the same guly results.

so it this a general issue or what is wrong on my machines/software ?

Chri

-

1

1

-

-

Hello,

i finally was able to create a own def.json for my printer.

i also was able to disable at least the M109 waiting for reaching the hotend temperature with :

"material_print_temp_wait": {"default_value": false

},

But i still was not able to disable the M104 command, i added the following lines

"material_nozzle_temp_enabled": {"value": false

},

also when using "default_value" instead of "value" the M104 command still will be written into the gcode file :(

Is there anything else that has to be changed to get rid of the M104 ?

Chri

Introducing: Ultimaker 2+ Connect

in UltiMaker 3D printers

Posted

I have some Questions, as i former UM2 Owner .

does the UM2+C still have that loud Hotend fan`s and 1/16 stepper drivers, have they been updated also ?

Sincerely Chri