It's definitely not just a single pass + travel pass. My calipers measure the support walls to be 0.8 to 0.9mm.

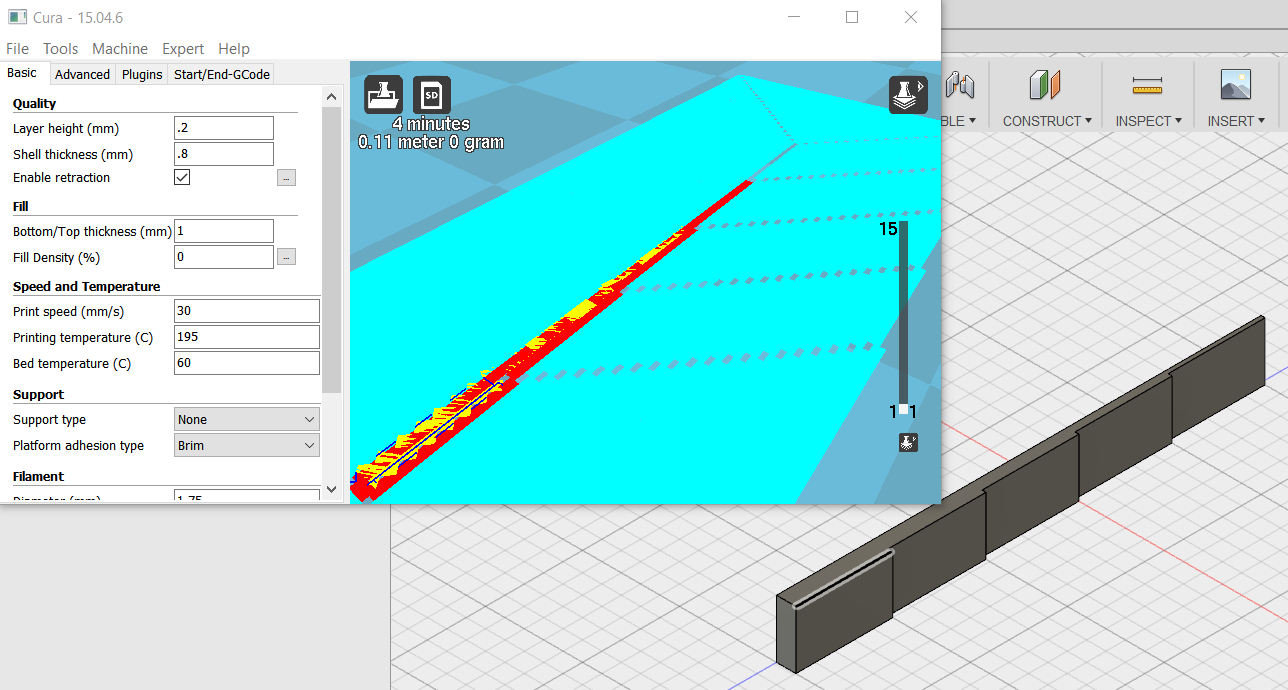

I've imported a test model into Cura 15.04.6. Here's the result (and you can see the original model from Fusion 360 in the background):

The widths in the original model are 0.21mm, 0.41mm, 0.61mm, 0.81mm, 1.01mm.

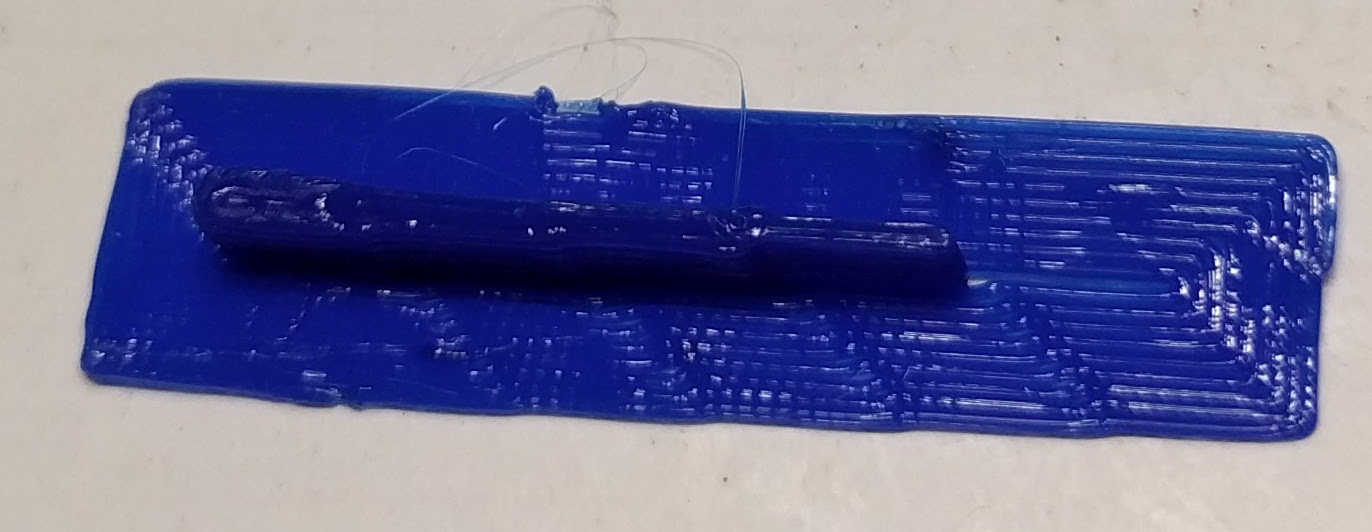

Here's the result from printing the model. It's a little hard to tell from the picture, but you can see it printed 2 lines side by side, even on the thinnest part:

The thinnest part of the model that printed is between 0.8 and 0.9mm:

This is the profile I'm using: TestPrintSettings.ini

Recommended Posts

DaHai8 74

Are you sure its not just making a single print pass and then a travel pass over it?

Have you check the Layer view in Cura to see if it is a single wall or not?

Do you have any calipers to put on the wall to see exactly how thick it is?

Cura 15.04.4

[/br]

Cura 2.3 (Release)

I've printed single wall items in both versions of Cura and not seen what you are experiencing. Perhaps there is a setting that's not right.

Edited by GuestLink to post

Share on other sites