-

Posts

1,148 -

Joined

-

Last visited

-

Days Won

21

Content Type

Forums

Events

3D Prints

Posts posted by amedee

-

-

I've been looking already but can't find a good source for the 4x4mm rods, any supplier tip?

Op 'spiestaal' zoeken, je vind zeker iets in je buurt voor 2 keer niets...

-

1

1

-

-

There is also a post here: https://ultimaker.com/en/community/35578-yet-another-e3d-v6-mount-for-umo

... and it is #GudoZGE compatible

I initially printed it in PLA (or nGen -- can't remember), then used it to print one in PC.

-

2

2

-

-

Wrote a long reply to a thread this weekend only to discover later that the forum trashed my post without throwing any kind of error. And I didn't feel like trying to reply all over again.

Happens to me all the time for various reasons, but the main one is that you take too long to respond -- there seems to be a timeout somewhere.

I now always 'copy' my answer before posting, so I can paste again when it goes wrong (which happens very often as I am not that fast in replying

).

).Another source of trouble is using emojis (easy to get that if you use a tablet, e.g. iPad often suggest emojis while you are typing).

And also don't change your mind in the way you want to answer (hitting 'reply' on different post will definitely confuse the software, even if you only enter text in one field)

-

1

1

-

-

Moi je prendrais plutôt un (semi) flexible...

C'est plus agréable au toucher. Je n'ai pas d'expérience avec les volants Momo, mais en général les volants ne sont pas vraiment durs (ne serait-ce que pour l’absorption de chocs...)

-

Sinon il y a truc super cool en ce moment c'est la B.A.W. tu connais ?

Dis nous tout ?

C'est un produit Breton ?

Tu ne connais pas encore le Breton-Anti-Warping?

Viens vite nous rejoindre sur Twitteur pour les bons conseild du Docteur @Riggs

-

2

2

-

-

Je plussoie pour la vitre propre -- je met rarement quelque chose pour l'accroche...

J'ai une feuille de Buildtak qui ne me sert que pour pour le PC (jamais essayé le Dimafix...) et pour le Nylon je met de la colle blanche.

@rigs, peux-tu élaborer sur les différences 3DLac/Dimafix? je n'ai jamais essayé ces produits, tout au plus un peu de laque...

-

I posted the initial answer from my tablet, not ideal for pasting the links, but here they are:

- 24v : https://ultimaker.com/en/community/44825-24v-for-umo-with-hbk

- My E3d mount : https://ultimaker.com/en/community/35578-yet-another-e3d-v6-mount-for-umo (dual fan setup at the end of that post)

-

Strange...

The only time I got a MINTEMP was because I had the wrong polarity on the thermocouple, so an increase in temp would make the display go down. But you already tested that...

MINTEMP is triggered when the temp reading is below 5°C, so unless it is freezing in your workshop, I see no reason to get that error.

Maybe for whatever reason it takes some time for the probe to give an accurate temperature reading and this triggers the MINTEMP at power-on.

Are you still using the original thermocouple amplifier?

-

Yes indeed, I also have an UMO with HBK and I installed an E3D hot end.

You definitely need the 24v version.

I initially mounted it "as such", so it gets 19v. It works fine, even for high temperatures -- I printed PC at 280°C in this configuration -- but it is does not warm up as fast as with 24v. If you consider using the Volcano 19v is probably not enough.

You can easily by-pass the 19v step down and use 24v directly, I recently posted an howto for that.

Re the mount there are plenty available, I posted my own as well.

-

2

2

-

-

Beyond the responsiveness of the servers, the overall architecture of the app is questionable...

Just going to the Forum tab, when there is nothing to display, generates 102 requests and transfers about 4 MB!

Whatever the connection speed is, it will take some time.

.

Then there is a HUGE list of 3rd parties involved on which you have no control: the same "empty" forum page sources code from 30 different sites -- only 2 of them controlled by Ultimaker (ultimaker.com and cloudfront) (and shall we talk about privacy ?

)

).

So it is not a big surprise to me that all this is sometimes on the slow side...

Using a privacy filter for your browser (like uBblock Origin) makes things a bit better though.

-

2

2

-

-

Note that if it has a green board it is an UMO, not an UMO+.

Also it is normal that not all driver slots are populated -- You need 4: X/Y/Z/Extruder 1; the fifth is for Extruder 2 and normally not used.

You absolutely need a cooler on the driver chip as they get very hot -- and as @tommyph1208 says you need to adjust the power with the trimpot (should be around 1.1/1.2 Amps)

-

Vérifies aussi que tes connexions sont bonnes du coté du lit.

Ton bornier est fort cramé et je soupçonne qu'il y aie un court-circuit à un moment donné. Ce serait bête de brûler le 2eme extrudeur...

-

I don't like the way it is explained in the manual, it is a source of trouble...

This is what I recommend:

- Screw the nozzle in the heater bloc, but NOT flush against the heater bloc -- leave approx. a 1mm gap

- Screw the brass pipe until it reaches the nozzle -- do not apply excessive force as it is fragile

- Now tight the nozzle against the brass pipe with a wrench. You don't have to over-tighten it, 0.5 Nm should be enough. At the end there still should be a gap between the nozzle and the block, if you are tightening against the bloc you will have leaks!

- Optional, but recommended: repeat the last operation when the hot-end is at temperature (don't burn yourself!)

Your bloc will never leak again after that

-

1

1

- Screw the nozzle in the heater bloc, but NOT flush against the heater bloc -- leave approx. a 1mm gap

-

J'attend toujours qu'ils changent leur modèle de license

-

Looks it is on the rails...

Sorry for not answering faster, I am out of town these days.

Having said that and referring to the github issue you filed, I am very surprised you cannot get your temperature under control with the PID auto-tune.

The 3DSolex cartridges do not require any firmware tweaks to work properly.

-

1

1

-

-

@amedee, short question: how have you hooked up the E3D amplifier?

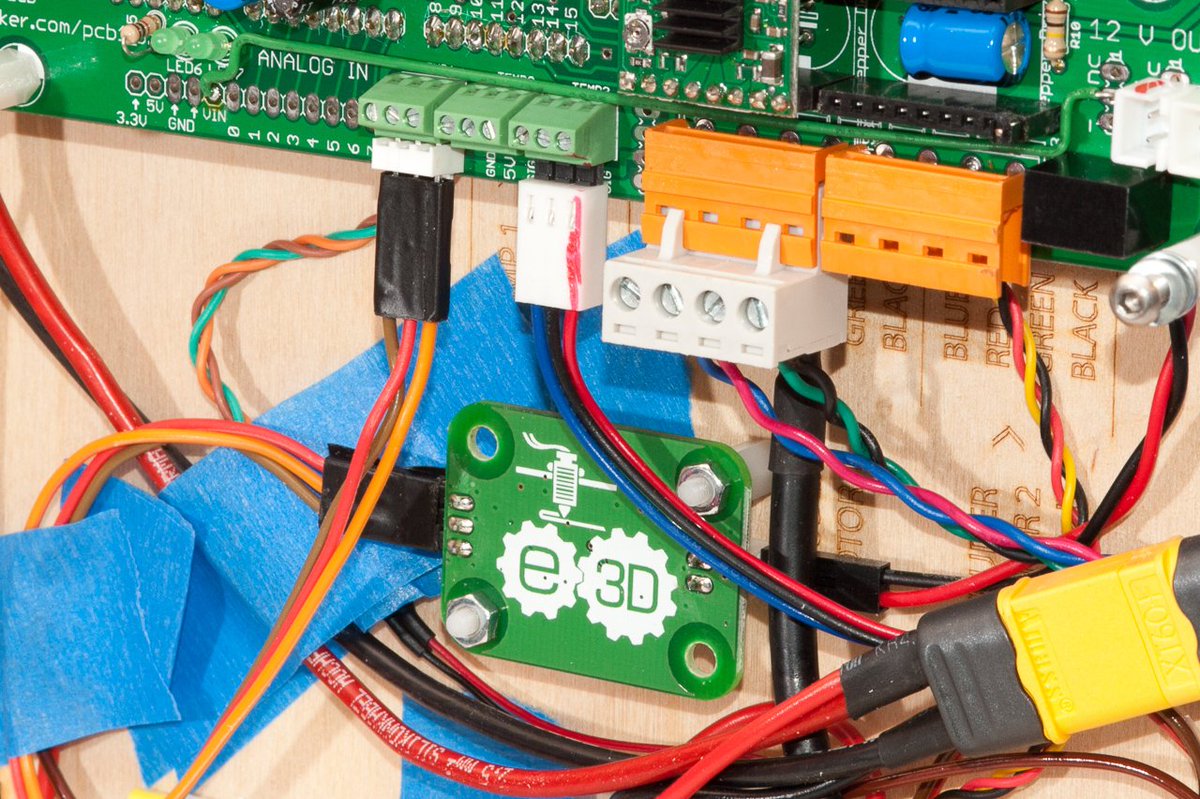

It is relatively straightforward, just connect to the 'temp' connector, as you can see on this picture:

.

Be careful, this picture is from my old 1.5.3 board, on recent boards the order of the pins is different (but it is written on the board)

-

1

1

-

-

If I'm correct the heater cartridge is 18V right?

UMO power supply is 19V

-

I always had to print a bit hotter on the UMO compared to the UMO+

I have no tool to calibrate accurately, so I don't know which one is wrong, but I did the same observation...

As I had recently troubles with the UMO thermocouple amplifier I replaced the sensor by a PT100 and the E3D amplifier. I have now more consistant temperature reading between both printers.

-

1

1

-

-

I measured the resistance of the heater cartridge (the two wite insulated wires) and it is 0.03 ohm.

This is way too less, it is just like a short...

I measured mine and I have a bit more than 10 Ohms, which correspond approximately to a 35W cartridge

.

Looks like you need a new heating cartridge (or there is a short somewhere in the cable)

-

Actually @neotko made a new topic for the announcement...

See here: https://ultimaker.com/en/community/46596-zero-gravity-extruder-v10

It is on YouMagine: https://www.youmagine.com/designs/zero-gravity-extruder-by-gudo-neotko-for-um2-and-umo-2

And my review video is there:

-

5

5

-

-

Indeed, I see no reason to go back. I still have to adjust my slicer parameters to get everything dialed in properly, but in the worst case, the ZGE performs at least as well as the Bowden setup.

If you would need to go back (e.g. in case you broke something like the stepper holder and need to reprint it), it is quite easy, you just need to remove the custom hot-end cover plate and re-install the Bowden. It is not practical to switch back and forth, but if you have to, it should not take more than 10 minutes.

-

2

2

-

-

Personally I don't think it's a power supply issue since the printer can be switched on, the problem occurs when I want to increase the temperature.

I don't think either, but it could be that the PSU is still able to provide enough current for the board (it does not need a lot), but gives up when you really draw power...

This afternoon I will measure the resistance in the heater cartridge, do you have any expierence with that? Can you suggest me some cables/connectors that I should measure?

Disconnect the 2 wires from the 'Extruder 1' connector on the top of the board and measure the resistance. I can't remember what it should be (I can check when at home) but if it is a short then it is definitely wrong.

-

If it is an UMO then it is an 'old' printer -- I not saying this in a negative way, just a deduction that it is not a newly assembled printer, and that it should have worked in that past...

So what did you changed recently?

At first I am thinking of 2 problems:

- Power supply as already mentioned

- A short in the heater cartridge (or the cabling to it), so when you start heating it shorts the power supply and everything goes dark.

I would disconnect the heater cartridge and measure the resistance to check for a short; also try to pre-heat with the cartridge disconnected: nothing should happen (except for a temp error after a while), but that would exclude a short on the board itself.

-

En effet pas de re-cristalisation, mais PolyMaker recommande une ´re-cuisson ´ (annealing) du PC-Max pour diminuer les tensions dans la pièce dues au refroidissement rapide lors de l'extrusion. On améliore ainsi les propriétés mécaniques.

Cela dit, je ne l'ai jamais fait, le résultat non recuit me satisfait pleinement et comme le mentionne @rigs je ne suis pas trop équipé pour exécuter un processus de manière consistante...

Problème remplissage en mode grille (UM3)

in Français

Posted

Le mode "grille" fait qu'il passe 2 fois sur les croisillons. Comme le XT se rigidifie assez vite, lors du passage de la cloison déja imprimée, cette dernière racle la buse et interrompt le flux continu ce qui a tendance produire ce phénomène...

Le mode "ligne" en général se comporte mieux dans ce genre de situation.