oups je suis pas complet, voici la suite

vitesse 1er couche: 30 remplissage 60 top/bottom 30 coque 40

epaisseur 1ere couche 0.26, ep couche 0.2

ep top/bottom=0.4 (soit 2couches de remplissage)

ep coque= 1.2

je vais recalibrer @duriel

voili voilou

oups je suis pas complet, voici la suite

vitesse 1er couche: 30 remplissage 60 top/bottom 30 coque 40

epaisseur 1ere couche 0.26, ep couche 0.2

ep top/bottom=0.4 (soit 2couches de remplissage)

ep coque= 1.2

je vais recalibrer @duriel

voili voilou

Épaisseur de couche dessus/dessous (top/bottom) essaies plutôt 0.8 mm

réduis peut être aussi la vitesse top/bottom a 20 mm/s

Edited by GuestPour que les ponts soient parfait il faut le fan à 100% apres quelques couches...

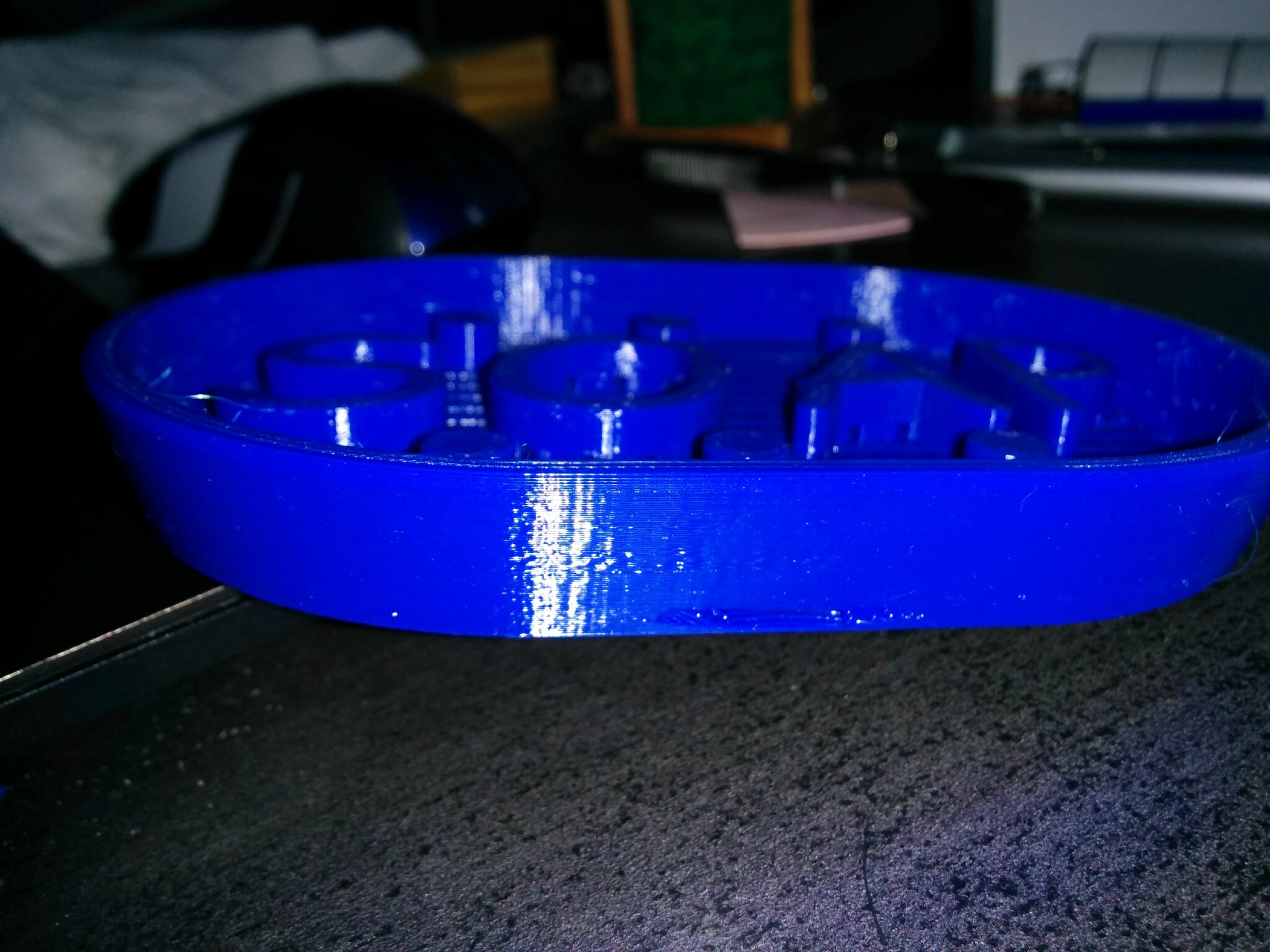

bon voila un 2eme essai, j'ai retouché legerement le designe

par contre je me pose la question

si on met 20mm/s dans l'onglet "simple"

cura en tient il compte dans l'onglet "avancé" ?

les parametres:

layer_height = 0.2

wall_thickness = 1.2

retraction_enable = True

solid_layer_thickness = 1.2

fill_density = 20

print_speed = 25

print_temperature = 235

print_bed_temperature = 85

support = None

platform_adhesion = None

filament_diameter = 2.85

filament_flow = 100.0

nozzle_size = 0.4

retraction_speed = 40.0

retraction_amount = 4.5

Recommended Posts

duriel 345

Bonjour @droj

Épaisseurs dessus/dessous tu es a combien?

Les vibrations indiquent que ton plateau est mal calibré, dans ton cas la buse n'est pas assez proche du plateau.

Pour le ngen, je suis plutôt a 235° temp d'extrusion, plateau 75°.

Tu ne nous donnes pas tes vitesses d'impression...

Edited by GuestLink to post

Share on other sites