I have the same problem but tend to design around it wherever possible. I'm not sure it's fixable unless you go to a heated bed. my parts are perfect until I prise them from the bed - then all that latent curling energy kicks in and bends the corners up, especially close to where I prised it.

- 2 weeks later...

Hi rewolff,

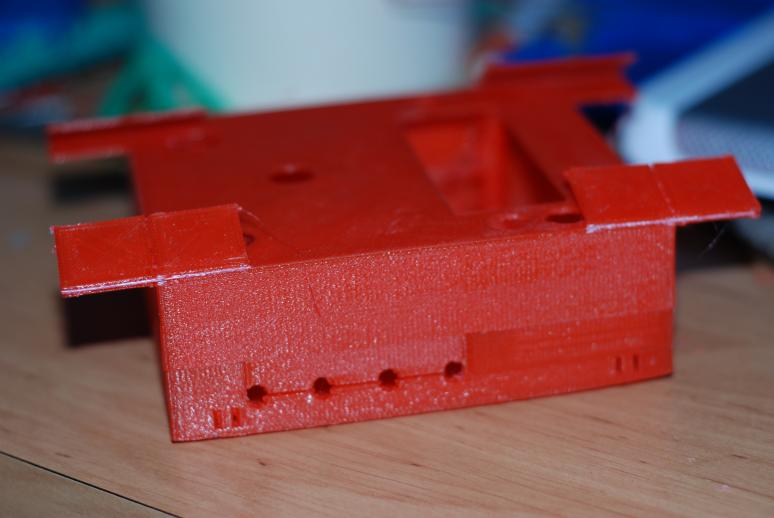

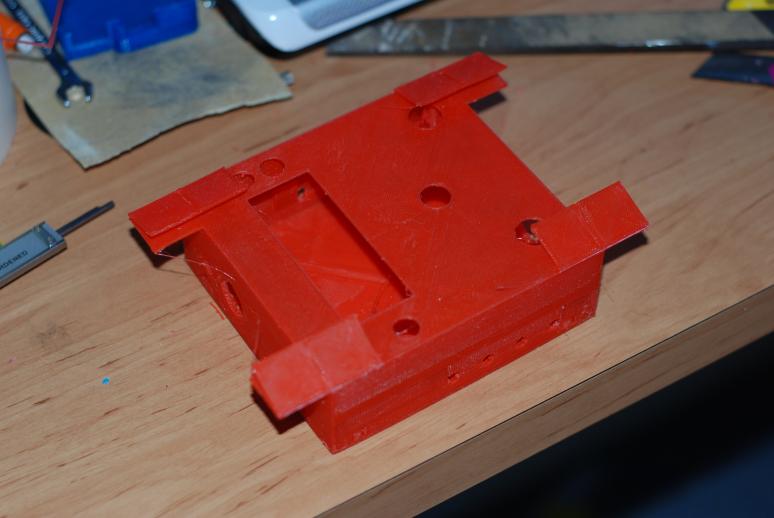

I had the same problem when I first started out with the Ultimaker (see attached image). Turns out, I wasn't waiting long enough for the part to cool down before pulling it off the stage, as such the edges were being pushed in as I forcibly rocked the part out of the tray.

benoit.

Recommended Posts

ian 32

a few little tips from my experience.

(1) make sure the colling fan kicks in straight away with your project, i run 130.

(2) make sure the walls that have contact with the base are a little thick, this means that when they form a wall, they are quite strong in themselves and that gives the model a better stronger start.

i still get a little corner curling but with these two little tips, it has got a lot better for me.

Also you could reduce the print temp to ... 215 or 210 for PLA and that would mean the PLA can cool that little but faster.

Best wishes.

Ian

Link to post

Share on other sites