-

Posts

257 -

Joined

-

Last visited

Content Type

Forums

Events

3D Prints

Posts posted by personal-drones

-

-

Hello Shnick, what apparently worked for me in a similar situation of chronic underextrusion on the UM2, getting worse and worse over time, was to change the teflon spacer, see http://umforum.ultimaker.com/index.php?/topic/9320-is-this-teflon-coupler-gone/

Not sure this will apply to your problem, but it might be worth a try.

Up to now I was never able to get a decent print with PLA if the layer height was over 0.1, because of underextrusion. 0.1 and speeds around 30-50 work well for me right now. The slower, the better quality.

-

Hello again fellow makers! I have a new patient (aka print) that i would need some advice with

Print settings:

Material: PLA

Layer height: 0.2

Shell thickness: 0.4

Bottom/top thick.: 1.2

Fill density: 5%

Print speed: 50mm/s

Temp: 210C

Bed temp: 60C

Diam: 2.85

Flow: 100

Retraction speed: 40

Ret. Dist. : 5mm

Here you can see how it's come out like for others: http://www.thingiverse.com/thing:224878/#made

The 0.4 shell thickness might part of the reason, maybe 0,8 would be better.

What do you guys think?

It is a difficult model with severe overhangs. 0.4 shell is surely not enough. I would try 0.8 or 1.2, print speed 30

-

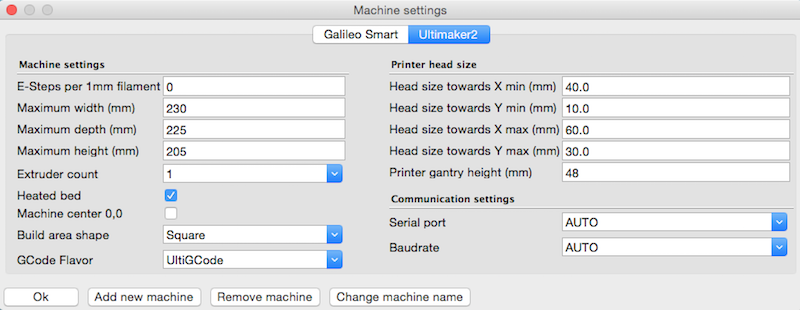

Wonder if by editing the machine settings you can fix it

Machine settings on 4.12:

-

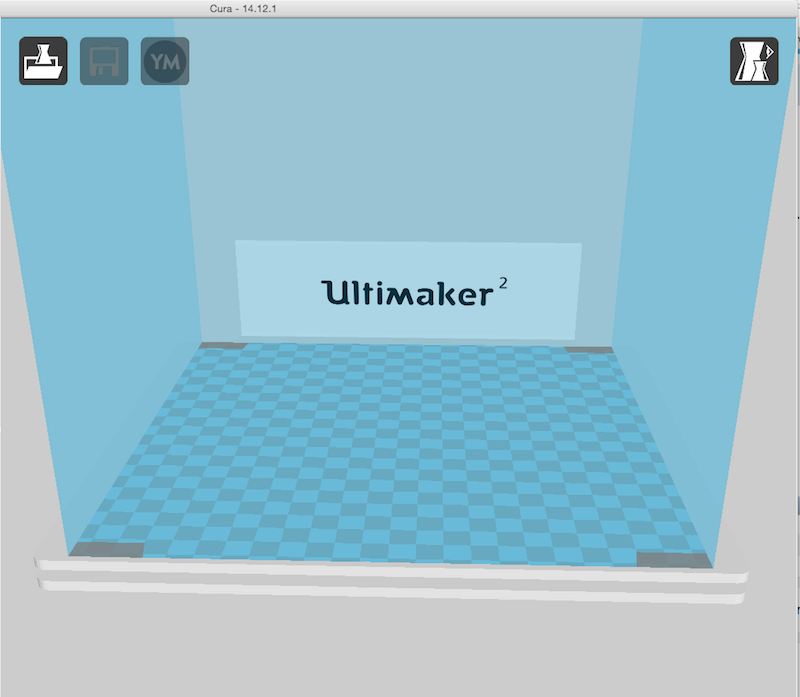

In 14.12 it does not stretch all the way, left and right:

-

I had the same underextrusion issue and replacing the teflon coupler did the trick.

Btw, I do my PLA atomic pulls at 210 and I've never had a problem.

Thanks TD. Will definitely rethink my pulls protocol

-

Swordiff thank you! So many things to look for, will go over all of them as soon as my current print is finished.

I do the atomic pulls at 260/90, as indicated in the official manual, but will now rethink that.

Thanks again, great feedback from you guys.

-

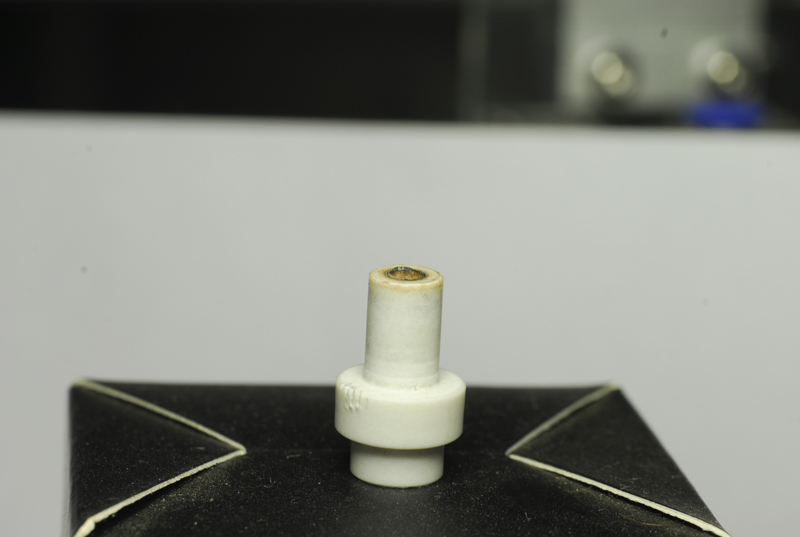

Whether you can save that teflon coupler or not depends on if it is deformed on the inside or not.

If it is just that burnt edge, you can probably get it back in working condition with a 3.3 mm drill bit.

Under certain conditions the teflon couplers deform though, which makes them unusable (for PLA at least).

Check korneels photo of how a badly deformed coupler looks when cut in half and try to determine if yours looks the same way inside: http://umforum.ultimaker.com/index.php?/gallery/image/11465-wp-20150107-014/

Yes Anders, this is exactly how mine looks if look closely inside. So I guess it is gone.

Do you think this this enough to justify the problems I described?

The currently ongoing print with the new teflon is still looking excellent after a few more hours, I guess this was it. I am surprised that the original teflon lasted so little, I have owned this printer for nearly exactly one month now. When the print is over I will look at the exact number of hours and post it here, for the record. Exclusively printed in PLA so far, never over 230°C.

Thanks!

-

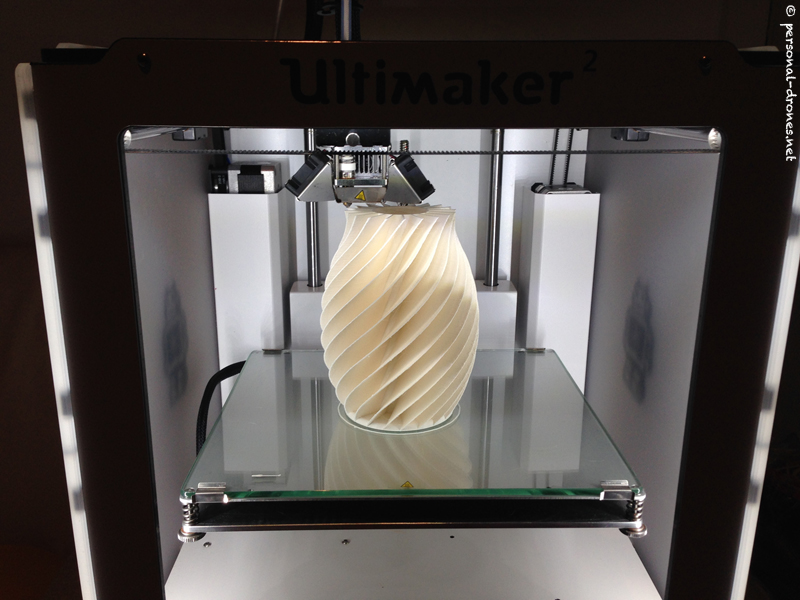

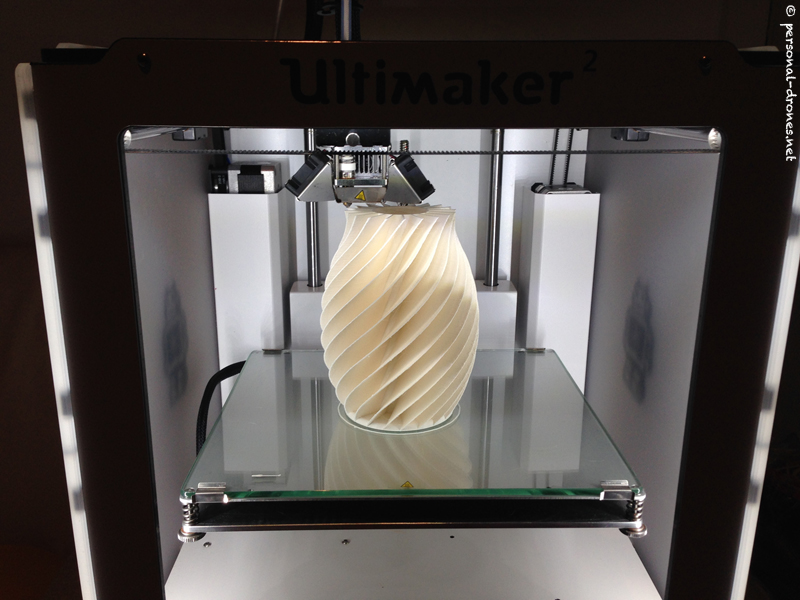

Yesterday I successfully printed out the first half of a vase:

When I launched the print for the second half (after a couple of hours from the end of the first part, during which the machine was shut down), I immediately noticed that the filament was having an hard time at coming out. Nearly no filament was coming out. Mind that the first half of the vase had printed perfectly up to the very top.

So I performed a first 2x atomic pull, the outcome was kind of clean, no particular residues or carbonized stuff. Material is white colorfabb PLA. Tried to print again, and again it did not look good.

So I took out entirely the filament from the bowden, with the idea that some chewing might have occurred on the feeding point, and that I would cut out all the last portion of the filament that had "seen" the feeder, and start over.

Did another couple of atomic pulls to be on the safe side.

Re-levelled the bed, just in case.

So I started over, and although I could see some signs of underextrusion at the beginning, then it looked good enough. I let it go and went to sleep.

This morning, I go in the room and the nozzle was going around, a couple of cm above the first part of the print, extruding nothing. So all the tinkering of the day before had been kind of useless. I definitely was having some problem.

I decided, from the shape of the atomic pulls, that maybe I had to replace the teflon coupler. Luckily I had bought one spare a while ago, so I could try that.

I replaced the piece, and now apparently the printer is like new, no signs of underextrusion in the last hour or so of printing the second half of the vase. I hope the problem is solved for now.

I would like to ask you guys, that have surely seen some teflon couplers gone bad already, if from the photos below it is safe to conclude that indeed the teflon coupler might have been the problem.

It still looks circular to me, not oval.

However it is like if a very tiny circle of carbonized teflon, at the meeting point with the hot end, has "extruded" outside. Not in a regular way. I think this shows in the pictures. Can this be the cause of my problems?

Maybe I can add here how much I am appreciating these forums. Without those, and the same problems I am experiencing, I would be totally in the dark. Conversely, with all the information available from the experience of others, I feel I am at least partially in control, and can also ask for advice and help. This is an amazing "collateral" value of my Ultimaker printer. I really want to stick to it and do all I can to have it run at best, as I believe it is a solid and special machine. Just love it, even if it is (still) not perfect apparently

EDIT here's another one:

-

Thank you Anders, good inputs.

-

Une misterieuse histoire, un vrai thriller. C'est passionant.

Personellement j'ai decide de prevenir, et de commander au moins un teflon avant que le mien me quitte. Je l'ai commande ici:

http://shop.creatr.it/it/accessori-e-ricambi/117-elemento-ptfe-ultimaker-2.html

et je l'ai recu en 2 jours (Italie sur Italie). Si ca peut aider.

J'ai vu que apparament il y a des "production alternatives" sur le forum, voire

ici, je veux essayer ceci aussi.

Bonne chance pour votre ordre, j'espere que tout va se resoudre rapidement- pd

-

I am following with great interest the efforts of the community to deal with the chronic underextrusion problems of the Ultimaker2, as indeed I do have these problems. I can get amazing prints,

but only if I print slow. As soon as I try some more "aggressive" settings in Cura, (say the default "quick" profile) underextrusion is there, waiting for me.

My general impression is that I am always "at the edge of underextrusion" with my beautiful brand new Ultimaker2.

Therefore it is nice to see that the community is aware of the problem and is working to solve these issues, both at the hot end. I am following these discussions with great interest.

I have a simple question here. I read that the original feeder system can "wear out" over time. Can I print a copy of it, are stl files available?

Thanks!

-

Details sur les pieces? Originales, materiel?

-

-

Ciao Andrea, così a occhio la posizione home in tutti gli assi deve corrispondere ad un rispettivo endstop. Solo grazie ad un endstop la stampante sa individuare un punto preciso in cui fare appunto home su un asse. Quindi l'idea di mettere la home al centro dubito che possa funzionare o essere implementata con semplicità.

-

Super, merci bien pour cette explication

-

Any chance it is time to change the teflon spacer? From what I read around it needs replacement sometimes.

-

Pour reparer les modeles j'utilise normalement:

https://netfabb.azurewebsites.net/

C'est un service online. Ca marche parfaitement, entierement automatique. Il faut faire un account microsoft, ca prends une minute.

-

Can you get a nice print with PLA right now, can you try that? The reason I ask is to check if the PET is the problem, or maybe you have a partially clogged nozzle that is causing underextrusion and the problem is not the PET.

-

>i put layer 0.3 because when i do 0.2 there is not coming enough material out off the nozzle

With a 0.3 layer you are asking the printer to output more material, not less, than with a 0.2 layer.

So if you have underextrusion, not enough material at 0.2, it will be worse at 0.3, not better.

Try 0.1, and/or print slower, this might help.

-

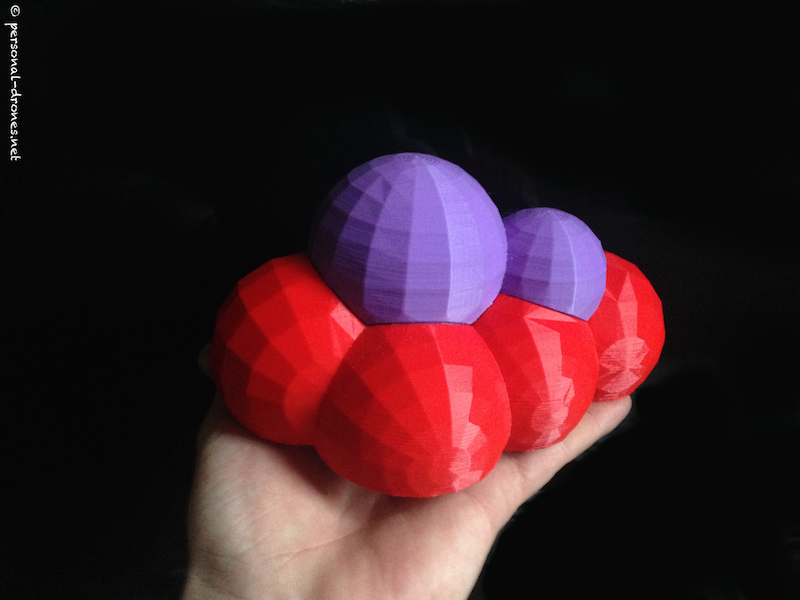

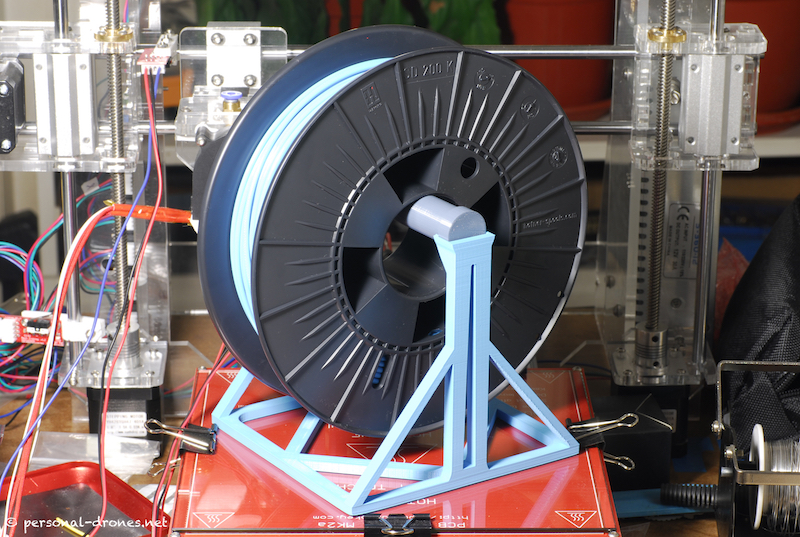

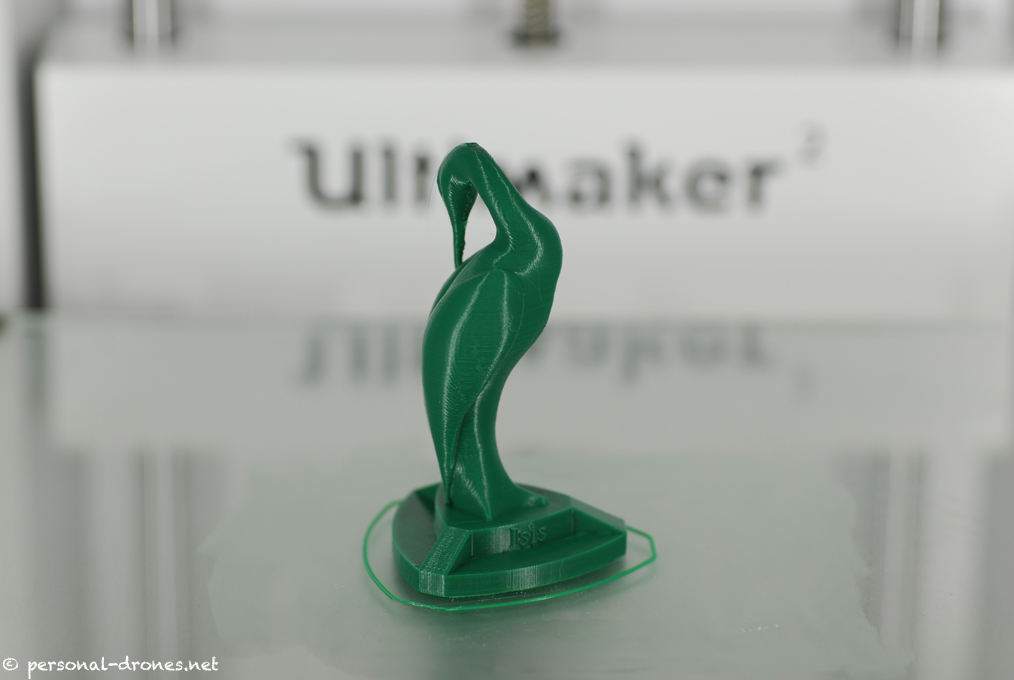

Ciao, potremmo raccogliere in questo thread links a modelli da stampare che riteniamo interessanti o che semplicemente ci piacciono.

Personalmente sono curioso di sapere cosa stampano gli altri. Passata la fase di entusiasmo iniziale in cui si tende a stampare un po di tutto (almeno a me è successo così), si tende a diventare più selettivi e a scegliere cose in qualche modo significative o utili, che tutto sommato sono una piccola parte del mare di modelli disponibili ormai sui vari siti. Per trovarli, sentire cosa stampano gli altri può essere utile.

Inizio io, con quattro oggetti che ho apprezzato particolarmente. Allego le foto delle stampe.

Low poly cloud storage

http://www.myminifactory.com/object/low-poly-cloud-storage-3526

Spool Holder. Semplice ed efficace, universale.

http://www.myminifactory.com/object/table-spool-holder-1631

Isis, bellissimo airone

http://www.myminifactory.com/object/isis-at-hyde-park-1395

Organizzatore schede SD, micro SD e USB. Utile.

http://www.thingiverse.com/thing:46335

E tu cosa hai stampato di recente?

-

Did you try to restore to factory settings in the menu?

-

C'est très bien fait, merci

-

A toothbrush can be your friend for this task. 180° should be enough for the job, probably even less.

-

Woofy I did not see it, looks very interesting thank you. I guess there should the final files online by now on youmagine, will look for them. Indeed I came to 3D printing through an interest in building my own flying machines: was constantly finding myself needing some parts that either were not available or costed too much. Finally landed on Ultimaker, very happy about this choice. :-P

Is this teflon coupler gone?

in UltiMaker 3D printers

Posted

As an happy ending, here's the final vase, glued:

And these are my usage stats after this 20h or so print (I replaced the teflon just before it):

So it looks like I had to replace the teflon spacer after about 340 hours of use with PLA exclusively, at 210-230°C.

Just for the record.