skinny-kid

-

Posts

85 -

Joined

-

Last visited

-

Days Won

1

Content Type

Forums

Events

3D Prints

Posts posted by skinny-kid

-

-

Your link is broken :/ and not only would that be expensive as you noted.. for me everything is double the price because international shipping to the USA.. :(

I was wondering if you had found something in the USA that works?

EDIT2: Amazon has 5' for under $15.

http://www.amazon.com/Fluorotherm-F015092-Fractional-Tubing-Semi-Transparent/dp/B00KJDE67G

I purchased this from amazon a little while ago and it works with no issues. It is a bit more opaque than the original bowden so lighter filaments are sometimes a challenge to see if loaded properly but I have no complaints.

The length is long enough to get two usable bowden sections that have ample space to trim as needed when the retainer clip chews it up.

-

-

Congrats Skint to you and your wife! Just remember you can use the sleepless nights to keep your printer running!

SK

-

1

1

-

-

What speed does the Dremel run at? Do you get problems with heat build up at all?

On my belt sander I have to take great care not to get the parts warm, it's very easy to melt them.

Dremel rotary tool with a host of different attachments. Sanding disks, wheels, brushes, buffing pads, etc etc

I also use the dremel 4000, it has variable speed setting from 5-35k rpm. The most I have gone to is 15k. It can melt the plastic if you aren't careful. Dremel makes a few different grades of sanding pads. They have disks also but I find the pads work well. They are rounded and allow you to work into curved areas without difficulty.

-

Dremel rotary tool with a host of different attachments. Sanding disks, wheels, brushes, buffing pads, etc etc

-

Thanks for the input Ultiarjan.

Going to give it a go and see how the print turns out.

SK

-

Hello to all,

I am working to print out a file that requires supports for a client. I am out of .4mm nozzles and have .5mm on hand (I also have .25 nozzles but trying to avoid using these for this job).

The model in Cura has the correct supports when I input .4mm nozzle size, When I change nozzle size to .5mm the supports generated are changed and I doubt the end result will be as good. There are parts that are going to be printed in the air with the .5mm nozzle.

What will happen if I tell Cura its a .4mm nozzle when its really a .5? I may be able to get a hold of .4mm nozzles later tonight but was curious about this.

Thanks for any input

SK

-

I have had my machine since February 2015 and have close to 4000 printing hours on it.

At around 3000 hours I had major issues happen and had the bearings in the print head for the x direction lock up on me. I sent the machine to Fbrc8 and they replaced the X motor, the bearings that were locked up and installed new belts since the ones I had were starting to wear.

After getting the machine back and running for a week I had the bearings in the print head for the Y axis lock up (unfortunately fbrc8 only replaced the one set the first time so I had to send it back to them.)

They indicated to me that they expected most machines to need belt replacements at about 3000 hours or so.

Hopefully I will get another 3000 hours out of the bearings as well!

-

Thanks for all the input guys. Had a friend help hold the wires in place and was able to solder connection back together. Tested fans with no issues, put new heat shrink on and printer back up and running.

Thanks again!

-

Thanks Ultiarjan

Can I solder wire to wire or do I need to take the piece off that is still attached to the white connector and re-solder the wire there?

-

Good day to all. I have been printing rather successfully for a while now and as I was changing filament I noticed that one of the green wires (for the fans I think) has come unattached!

I am not sure what the connection is for.....I do not know how dire the situation is. Can I continue to print or do I need to fix this immediately?

Sorry for all the questions, I am more of an artist than an engineer. Can this be soldered and re-shrinkwrapped?

Thanks in advance for any help.

-

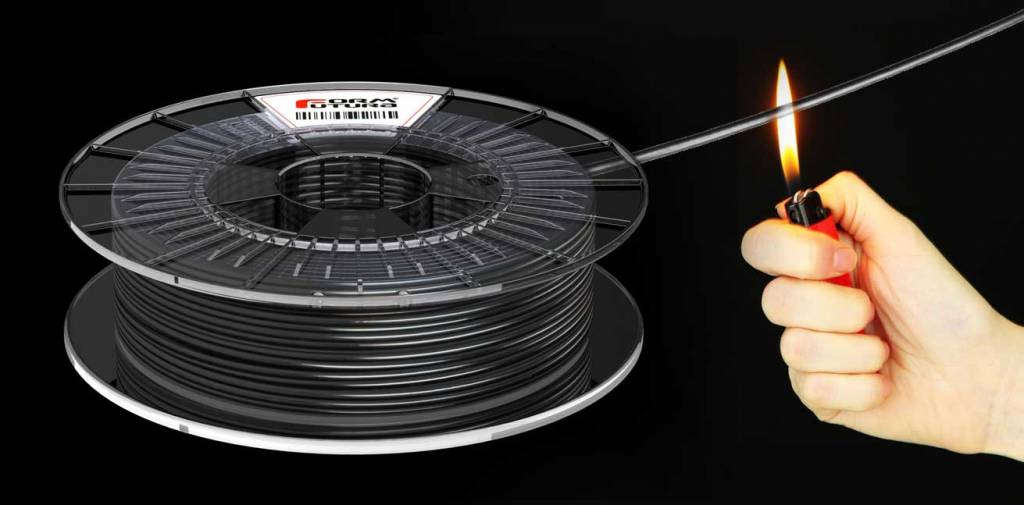

more interesting filament developments.....just saw this from FormFutura

Within our professional ABSpro™ engineering filament range we now offer a revolutionary flame retardant variant called “ABSpro™ - Flame Retardant Black”.

ABSpro™ - Flame Retardant Black is new halogen free self-extinguishing filament which is engineered to meet the UL 94 V-0 flammability standards, meaning that the vertical burning of the filament, or 3D printed object, stops within 10 seconds.

And as a bonus......

Use the discount code ABSFT to get an introductory discount of 10%. This offer is valid until Sunday December 6.

-

Glad to hear you got it sorted and your machine is running smoothly again!

-

-

-

Pet is simular to xt so should be fine

Thanks for the heads up Labern!

-

Do the pieces need to printed in XT or XT-CF20? I mainly use PLA and PET

If they need to be then not a problem, option A seems the most flexible.

-

Can I ask what filament you are using? Have you tried printing them both together rather than sequentually?

I ran into a problem with Ultimaker silver filament when I first started 3D printing. If I didin't let the head cool all the way down and tried to run a print before then, the second print would not print correctly since the nozzle had a clog. I would have to atomic pull and make sure all was clean before running again.

If I waited until the head and the bed had cooled, then I didn't have this issue.

It may be what you are dealing with. The problem for me stopped when I switched to Colorfabb and Faberdashery filaments.

-

I recently printed with a roll of Bronzefill with great success.

Printed items at .2 mm at 210 and 40 mm speed on Olson block set up with .4 mm stainless steel nozzle, bed at 50.

Doing finish work with patina stains and solutions has been fun with this stuff.

I just received Copperfill and Corkfill and will be printing with them within the next week and will let you know how it goes.

-

1

1

-

-

Count me in as another person interested in your design. Excellent work you have done thus far!

-

Hi

Try :

Wall thickness 0.4 mm

if it don't work trying to expand the model.

Thanks Rigs

Moving Wall thickness to .4 and adjusting model size seems to have remedied the problem. Thanks!

-

Good day

Been working on a few things for the Christmas holiday and have encountered an issue that haven't seen before.

Normal view for cura shows entire model as it should be, later view shows something very different.

Modeled in Maya, exported as stl, checked in netfabb. Other designs I have done do not show this.

Any ideas?

Wall thickness is set to.8

.4 nozzle

speed at 40

100% infill.

Pics explain it better

-

-

Yes, Thanks! I received my mail yesterday as well!

Horrible noise from y-axis

in UltiMaker 3D printers

Posted · Edited by Guest

That sounds like the bearing in the print head is starting to go. I had the Y and then the X bearings go out two weeks apart. My machine was still under warranty so FBRC8 in the USA took care of it for me.

Is the print head difficult to move in the Y direction? Have you lubricated the axes recently?

I just got additional bearings, to have as back ups in case it happens again (I have noticed increasing noise from my printer). I believe the bearings are LM6UU if your warranty is expired.

There is a recent post here about replacing the bearings in the print head.

https://ultimaker.com/en/community/19405-loose-bearings-in-um2-print-head