As @DidierKlein says, get yourself a new teflon coupler if you haven't changed it in a while. Try atomic pulls first to make sure the nozzle and brass tube are clear.

In my experience, if the coupler is worn (e.g., no longer seals well against the PEEK isolator, you will get filament jams after printing a while as the heat transfers upward toward the coupler and the filament softens--especially if you are doing a lot of retractions.

Recommended Posts

DidierKlein 729

Hi,

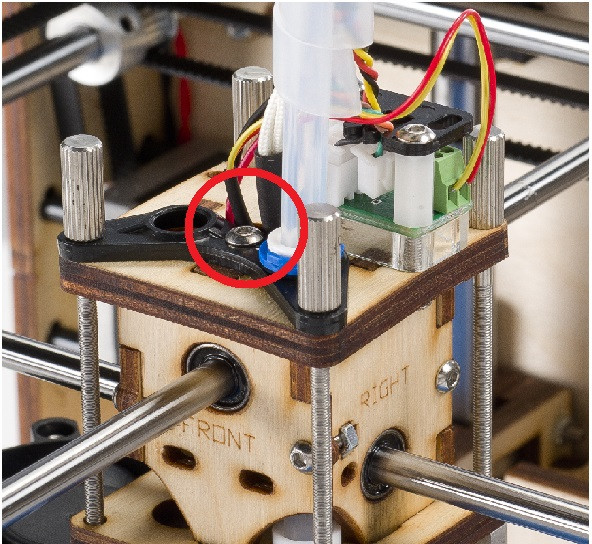

There is no pictures attached!

How many hours of printing has your machine done? Maybe it's a good time to change the coupler?

Link to post

Share on other sites