@amedee, short question: how have you hooked up the E3D amplifier?

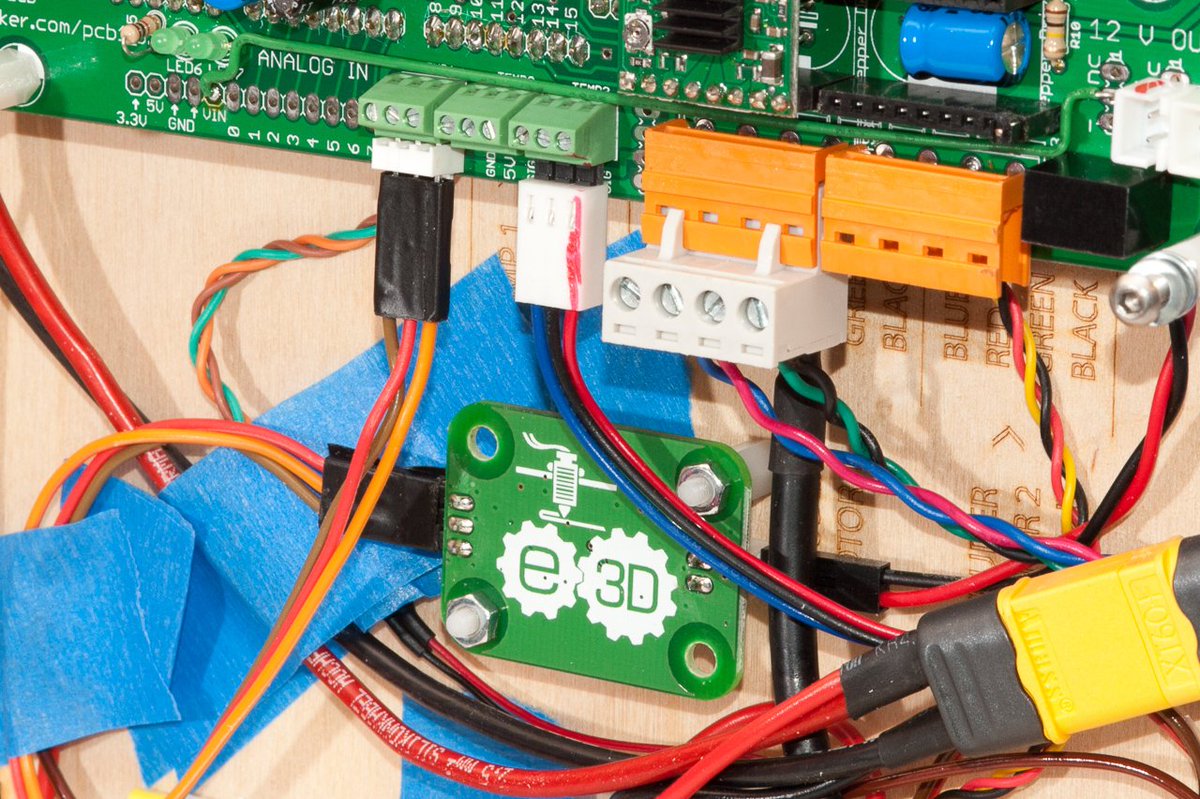

It is relatively straightforward, just connect to the 'temp' connector, as you can see on this picture:

.

Be careful, this picture is from my old 1.5.3 board, on recent boards the order of the pins is different (but it is written on the board)

-

1

1

Recommended Posts

amedee 349

I always had to print a bit hotter on the UMO compared to the UMO+

I have no tool to calibrate accurately, so I don't know which one is wrong, but I did the same observation...

As I had recently troubles with the UMO thermocouple amplifier I replaced the sensor by a PT100 and the E3D amplifier. I have now more consistant temperature reading between both printers.

Link to post

Share on other sites

drayson 75

Link to post

Share on other sites