I would potentially be interested as this is on my to-do list, but the shipping and import fees to Canada probably wouldn't make it worth it. I was also thinking of going with a frosted glass surface for more surface area and better adhesion.

sxt is that where you got yours? You really think it needs to be tempered? I read a couple of blog entries that said make sure it's not tempered. One of the reasons I wanted to go water jet is so that I preserve the stock slots. I'll email those guys and find out if can do that.

Didn't think of the frosted glass.. I wonder how that would work. Might be worth a test and find some cheap thinner frosted glass and slap it on top of the acrylic.

Yikes!

Then I should go ceramic glass.... I wonder how expensive that is.

You can not cut toughened or annealed glass they are secondary processes ![]() ie more cost and delay. I just tried it at work as 6mm glass was about $35AUD per meter. I would just use aluminium as its more robust and only expands < 0.5mm.

ie more cost and delay. I just tried it at work as 6mm glass was about $35AUD per meter. I would just use aluminium as its more robust and only expands < 0.5mm.

I also had to scale the key ways in the thingiverse AI drawings by 1.15 in Rhino. the final version is on my thingiverse page

http://www.thingiverse.com/thing:17747

I am meeting with the glass guy tomorrow... If that looks like it's too much of a pain then I might just do the aluminum thing.

- 2 weeks later...

guys silly question but when you buy a ultimaker, it comes with a build platform.

why do you need another ?

thanks.

Ian ![]()

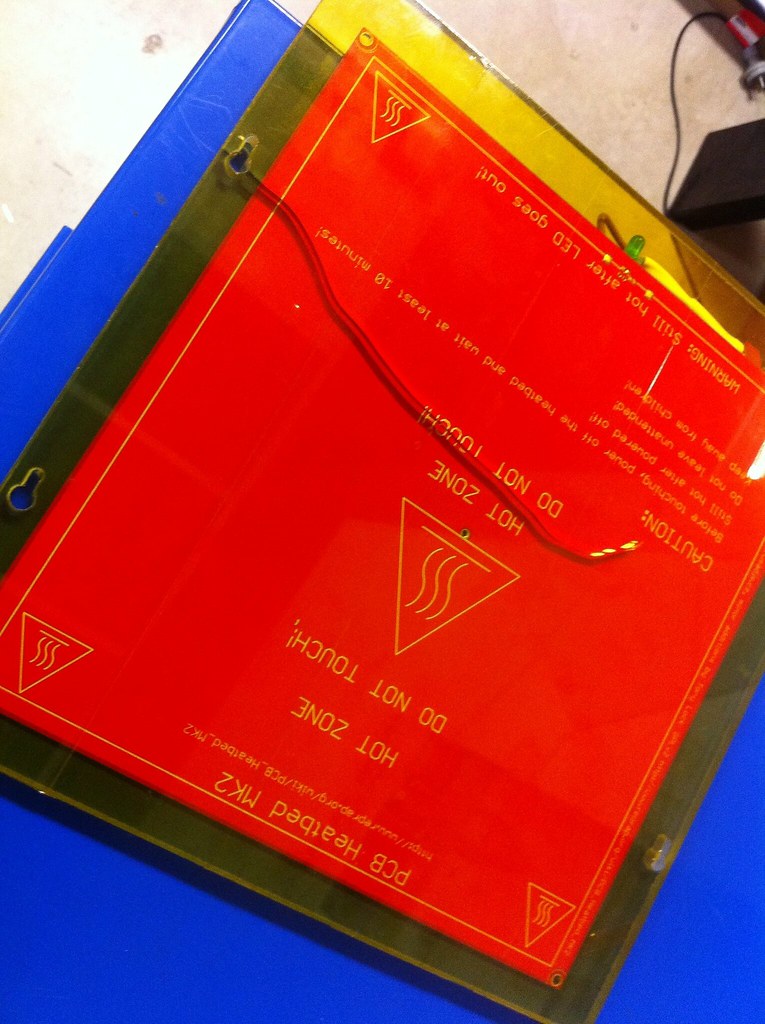

I am building a heated platform, the stock one is acrylic which won't play nice with heat. ![]()

Also preference too, some prefer the qualities of glass or the thinness of aluminum.

Chuck

and what can you do with a heated working platform ?

Ian ![]()

Printing ABS.and what can you do with a heated working platform ?

A heated platform helps to stick the first layer down, it prevents warping, and makes it easier to remove large objects from the bed (after cooling down, print pops off)

I'm renovating my bathroom at the moment. And while I was taking down the tiles, I was wondering. Could ceramic tiles be used as heated platform. I did some searching, but didn't find a lot about it. Ceramic should be stable at higher temperatures (no bending), but not sure how thermo-conductive it is.

That's funny... I was just doing the same thing. Just laid in 12" tiles in the bathroom and thought the same thing about a heated ceramic platform. The tiles I put in where not flat enough but the surface quality was perfect. Super hard and resistant to chipping and scratches.

AND very thermally insulating. There's a reason why they use ceramic tape to insulate reprap hot ends... space shuttle tiles, etc. (not that your bathroom is made of the same stuff that the space shuttle is, but they are both ceramic materials). I imagine it would take a lot longer to heat up plus might have uneven heating... What is wrong with aluminum?

It bends under uneven heating? But I guess aluminum works fine. I was just wondering, because I suddenly had a huge surplus of them. If it's a thermally insulator then it's a bad option.What is wrong with aluminum?

I've got a glass plate to print on. Just got myself some glass somewhere, bought a glass cutter and cut the glas down to size.

Not sure whether this glass is thermostable. But heating it up slowly might minimize the risk of breaking/cracking. The heat needs to be spread homologous otherwise pressure builds up in the glass.

I think ceramic tiles will do just fine. I put one for testing in a 'patio fireplace' thing. I turned up the heat by adding oxygen with a compressor. I put in some aluminium to. The aluminium melted, but the tile stayed the same. But my guess is it takes some time to heat up (and cool down).

- 5 weeks later...

sxt is that where you got yours? You really think it needs to be tempered? I read a couple of blog entries that said make sure it's not tempered. One of the reasons I wanted to go water jet is so that I preserve the stock slots. I'll email those guys and find out if can do that.Didn't think of the frosted glass.. I wonder how that would work. Might be worth a test and find some cheap thinner frosted glass and slap it on top of the acrylic.

Sorry for the late reply, I totally forgot to click on "notify when reply posted". Yes, that is where I got mine. They are pretty quick and I got it was exactly as ordered. I like them because they specialize in one-offs and they do ceramic (tempered) glass or all shapes, thicknesses and sizes + they can drill holes in tempered which is rare.

I would advise going for tempered. It's not the actual temp that the glass rises to, but it's more about the speed at which it heats up and cools down that can cause cracks.

.thumb.jpeg.0b7a05eafc09add17b8338efde5852e9.jpeg)

Recommended Posts

sxt173 0

I already got a glass build surface (not for Ultimaker, no ultimaker yet actually..), but did you check onedayglass.com? They are in the US, have reasonable prices for one-offs, they do tempered (which I would highly advise) and can drill holes too.

Link to post

Share on other sites