-

Posts

183 -

Joined

-

Last visited

-

Days Won

2

Content Type

Forums

Events

3D Prints

Posts posted by yzorg

-

-

-

Sourced in Obi Switzerland..

pay attention not to buy anything with abrasive stuff in it. translucent nylons are pretty save.

says is made by husqvarna(sweden) in china.

www.uoa.cc

Specs:

Dark translucent wine-red

3mm diameter. (also as 2.0 and 2.4 available)

10m coil

8.- swiss francs

i tried with default Taulman 645 settings..

245°C no fan and slow.

plus my blue tape sprayed with fixative (lascaux)

also i got me a coil of electricians pull-trough wire. also 3mm nylon in white.

-

update:

thx to all helpers.

a more precise inspection with magnifing glass showed light damage on nozzle tip and build up of hard plastic residue.

cleaning with some strands of copper wire and grinding the tip with 800grit paper (in hot condition)

now it prints like a new nozzle again.

I think we should put some development in a good and easy practice to swap nozzles.

I like the JHead principle.. but theres still room for improvement.

This way we could dedicate nozzles to specific materials (nylon, Abs, PLA...)

Nozzle cloggs are now minimized to a single material and thereby we could introduce use a fitting simple cleaning procedure per material.

(like solvents, heat, ultrasonic, mechanical..)

next i am trying to get the "chess" hotend from 2engineers.com to work.

a flyhead design is in printing process.

-

does anybody know how long exactly the extusion-button extrudes filament? looks like like 5mm but nothing is safe. its not written anywhere.

i would like to recalibrate my esteps.. due the wear.

looks like i cant do this with cura anymore.

also its very unconvenient that in cura machine settings ther is a Default"0" instead of the actual E-steps per mm.. i cant do the math without..

-

i would like to know the exact e steps cura uses... it only displays 0 in the settings. thats not very helping.

-

yep i think so. but its strange..

the last hotend changes i made are back some months. it used to print until last week..

so i guess i got lucky and just mounted it super perfect back then.

also i got me a ceramic hotend with jHead mount..

maybe i redesign the whole flyhead in future. but until that i need some more printed parts.

heres the latest test.

normal profile, slowed down to 80%

-

thx for reply.

I have the V2 hotend.

i checked temp. is stable

tightened all bolts.

the delrinwheel runs freely. i added a washer on one side to center it over the Filament. (removed for testing sometimes)

i cleaned the hotend as far as i could...

i noticed that i didnt had that small white teflon piece in there. (i have an additional cold-end fan)

also i couldnt find it in my UM-partsbin. but i now i had one in the V2 kit. i might need to order a new one.

update:

i can print again but only back at 70%speed (dialed at controler), cura normal profile.

would be interesting to see how other 3year old extruders look like..

maybe someone posts me a pic.

-

hi guys

my machine is getting old. eventually..

I am getting quite bad print quality lately. couldnt resolve it yet.

my parts more and more got the so called "airprint-feature".

They come out crunchy.. useless.

Extreme slowing down kinda helps getting something printed. but not realy.

adjusting the feeder tension didnt help eighter.

I want to find out where the problem hides.

Its not consistant though all layers.

Strangely some layers are printed nice.

(doesnt look like that is coming only from backpressure)

Some lines dotted, at least 50% of the printed line is too thin.. Perimeter and other walls dont touch each other anymore.

Heres what i did trying to solve it:

First i finetune in ulticontroller.. didnt help.

Then, remeasured the grey Filament and updated cura.

Grey 3mm Filament with Tolerances about 2.92mm/2.96mm (from E3D)

When i cut it, it looks quite round to me..

So did a reset to default in cura. and reset ulticontroller. (back to failsave)

Problem stayed...

Then i tried cranking up Flow on the Ulticontroller midprint, it gets better for some layers but not for long..

For testing purpose i loaded mutliple older PLAs, but all showed the same effect.

The Grey filament is brand new..

So i went though all possible places where it could jam, block, grind or else.

Disassembled Hotend and Extruder..

As far as i see thers nothing bad on hotendside.

The extruder took some beating over time.. (3years, machine runs on daily basis)

I think this is also because i use a lot of matte Filaments lately. they have a higher abrasive effect than glossy filaments..

(didnt order matte filament on purpose.. that webhop sold it as normal)

As Fix i turned Part 10A and 10B. so now they "use" their new side.

The Delrin plunger has been eaten over time too. so there i put in the still new upgrade Feeder with spring.

But sadly the problem ist still here..

So.. only can be a partly clogged nozzle then ?

:(

a week earlier.. same filament, same machine

-

hi guys

wanted to ask if this happens to others too.

sometimes when i quit cura14.01 it crashes instead.

i had this in earlier versions too..

this only happens when i have some quite high poly meshes loaded..

It doesnt bother much since Slicing and saving gcode works fine with those models.

greetings

-

my thoughts,

i wont migrate from thingiverse because i just have to many things there.

i have to use paralell accounts.

Youmagines upload process should be simplified.. best would be one page with all buttons on it.

i like to have more categories or sub-categories though.

For me the overall webdesign has too many colours and too many small elements. its wild.

maybe some designed layoutlines to guide the eye could help.

youmagine (many other websites do this too..)

only use about half of the available space on a Macbookpro laptop screen (15).

is this realy intended?

i think its a bit waste of screenspace.. and i hope its not only because of more and more mobile browsers.

Deviantart.com is a good example of nice content versus whitespace dispersion on screen.

"Ultishaper" should come standalone and offline.

I never use online-editors if i dont realy have to. same goes for all designers i know.

I hate how slow most web apps run.

Plus i like to have my incremental saves on my own discs.

-

I got it to work. just cut the tab off of the one end of the plug. so you can plug it in 180 off. you want the red strip of the wires by the switch side.

Can you maybe send me a picture of your modification?

i cant understand by text what exactly you did.

for example what 180off means or the red strip..

thx in advance

-

nope. but also not much time went into testing yet. holydays...

-

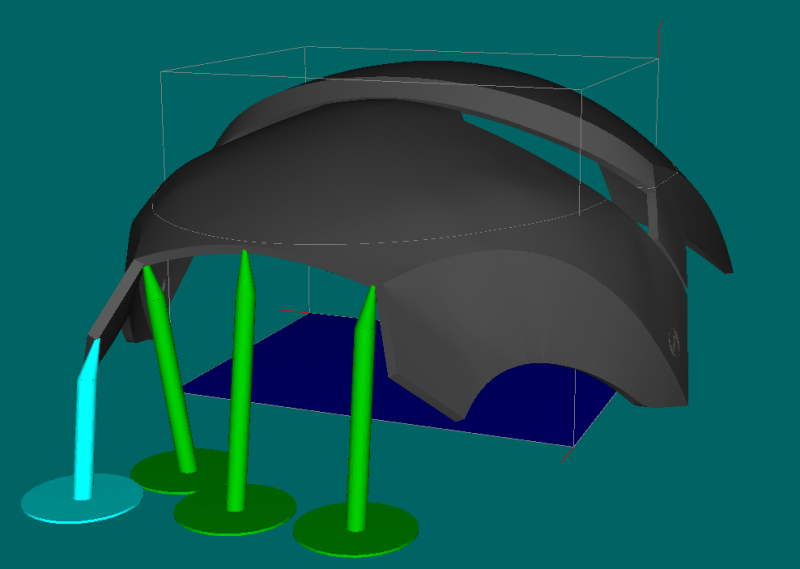

Don't get me wrong, but I think this kind of support is for Stereolithography, and not really suitable for Ultimaker.

you might be able to bridge some spans with certain settings, but you really need support with a larger surface area.

(I wish Daid would bring back the old style, easy removable, support back)

in my experience, the new support in cura works fine if adjusted correct..

And these support colums also work fine in ultimakers if made thick enough. Plus they can save lots of support material and print time. Especially when Combined with Curas automatic support.

This can give you the finest possible control over support structure.

You will be able to print your objects in nearly in any orientation.

a hop-over plugin can help if collums get nocked over... but with the right speed they dont.

-

I found another software that can do these supports quite useful:

B9Creator software. (is a bit print size limited.. but opensource)

... my Meshmixer happens to crash sometimes. sadly all Autodesc mini apps do.

It has nicely adjustable support collum system and all can be saved to .stl

the interface is quite convenient in my opinion.

link:

http://b9creator.com/software/

-

Yesterday I experienced something really weird:

I had this delivery of filament: Nylon,Laywood, Bendlay and 2kg of white PLA from mexhibit (german vendor):

This PLA was delivered on two very small spools a 1kg each, that wouldn't fit onto my UM. So i took the material of one spool and put it on an empty 2kg-reel i had laying around. Put this in my newly build exsiccator and left it in there for about a week now.

And yesterday I came home to this:

http://umforum.ultimaker.com/index.php?/gallery/image/1862-pla-drying-crash/

I made the exact same mistake... i now have quite some unusable filament lying around.

i hope i can recycle it with my filastruder in future.. but i need to build a shredder first.

-

thx for the hints guys.

i got one now and try to make it work on my spare Ultimkaker board.

on first test it stays dark and beeps occasionally...

swapping the cables makes it screambeep and the back light flashes.

so i think i have to go into the config.h...

i will need an arduino specialist to make this work.. i cant do much in arduino.

The RepRapDiscount will work, but you should rip off the reset button, as pressing it would short out the power (as the UM electronics has a power line instead of a reset line on that connection)

Does this removal of the button change anything directly or can i leave it there and just make it unpressable?

do i have to solder some bridges after removing the buttion?

-

Hi guys

I recently stumbled over those LCDs that are quite a bit cheaper and would also result in much less shippment costs to me than the one from the Ultimaker-shop.

http://fabber-parts.de/shop/index.php?a=130

pic below..

The only optical difference i notice is the stop button.

Sadly i couldnt find the pinout plan of the connectors yet...

Could it be possible to use those "cheap" LCD-controller on the Ultimaker 1.5.4 board? i know its intended for Ramps 1.4... but isnt ramps quite similar to the Ultiboard anyway?

greetings

-

ah cool,

thx for the hint. i use cura 13.10

but the Autoupdate wont load the 13.11...

going to check manually.

-

Im perfectly happy with Cura. but i never stop testing

I found "Mattercontrol"..

has a very nice interface. very clean design, customisable.

only Mac and Windows though...

-> Slic3r and Cura slicer are both integrated...

With Mattercontrol i can have slic3rs continuous Z-raise again (spiral Vase)

Download Beta an test it.. here your go:

Post your experiences..

-

Hi guys,

I drop in my first experiences with Bendlay..

Awesome stuff i have to say. it works good with a bowden system.

Not too bendy not too hard.. and very smooth surface (ultimaker soft pla is much softer and kinda bit stickier to touch in comparison)

I used the proposed 240°C this worked fine.. (im still experimenting with Fan off or on and temp changes)

i forgot about the material density settings.. so i used PLA 1240 kg/m3 .. worked fine.

( i exeriment with this later)

I activated Raft... (also made the interface raft layers stronger.. from 0.2 to 0.4)

The best stick-trick i found was Kapton tape with a spray of acryl based fixative. (most people use hairspray instead)

Even though i recommend a HBP.. for some prints this worked even with a cold buildplate.

Heres what i used:

Lascaux Fixative

http://lascaux.ch/pdf/de/produkte/malhilfen/firnisse/52313.01_firnisse_.pdf

Pay attention not to spray the buildplate when it sits in the Printer.

The spraymist will go everywhere... and we dont want to know what it does to moving parts.

-

just changing the ending and its done?

thats easy.. but why the change in the first place?

edit: nevermind..

i researched it.

-

i miss the ability of cura being able to save back to STL..

now it only saves as .amf which i cant use anywhere.

was a quite useful function. I used it alot.. to save arranged buildplates(for non-separated print) or different scalings of objects.

also i used it save mirror actions to the object..

i could do all this in the 3Dprogram i used to design the parts.. but its very convenient to save last changes anytime.

-

hm. yes thers no joris.

but i got nearly seamless bracelets and other vases by using the 0 infill and unchecking solid infill top and bottom.

last version i used didnt had these checkboxes

-

have to bring my gratulation on this update :mrgreen:

very useful features have been added/brought back.

i love making "vase" prints again!

Also super nice to have mutiple machines.

Because right now, i have one ultimaker, a reprap on marlin and a big cnc-mill also powered by ultimaker electronics...

So, this is uber-praktical for me.

The movement speed of the bed leveling process a is a bit extreme.. but nothing happened.

Are there also bigger firmware changes inside?

Nylon on a UM2

in Coffee corner

Posted

i use superbig rafts (both layers maximum settings) on Blue tape sprayed with fixative.

Still, sometimes the print warp so strong.. they are able to pull the tape from my buildplate.

i have yet to try masonite as build-surface.

if you want to try a cheaper alternative nylon.

check this tread:

http://umforum.ultimaker.com/index.php?/topic/4264-another-nylon-trimmer-line-found-working-as-filament/