-

Posts

234 -

Joined

-

Last visited

-

Days Won

1

Content Type

Forums

Events

3D Prints

Posts posted by Wisar

-

-

Talk to @labern. He hooked up a laser to his UM2 and I think he used the fan PWM controller. Laser's don't mind being turned on and off 10X per second.

I will reach out to @labern. Using the fan directly would simplify things greatly. I am a little ahead of myself as I don't even have the laser yet...but...I already have a GCode pre processor written that would work directly with the FAN PWM if the laser doesn't mind it.

-

Have one on order and have started some of the preparation work. Did you ever pull the trigger and get one?

-

Why not just take the led pwn? Is Gcode control-able. And you have a laser, no need for led light

I had no idea the LED was gCode controllable ("M42 S0" and "M42 S255") as that is an alternative. The laser kit that I am using is the L-Cheapo. It is a 3.5w laser so theoretically I guess I could drive it from the LED output though I am a little worried about possibly shorting it out and killing the dimmer function on the main board (from another post elsewhere here). Also wonder if a laser be driven by a PWM output?

My idea with the fans was to intercept the power supply to them and insert a low amperage current sensor connected to an Arduino. The microprocessor detects the fan being turned on and activates a solid state relay to turn on the laser. I happened to have most of the parts to do this as I do a lot of microprocessor projects.

On the firmware side...I don't want to touch the firmware so have written a Python script that pre-processes the gcode. I start with a Simplify3D profile that uses ooze control to insert retractions that I can then detect in my script. The script sees a retraction and turns off the fan (and laser). The next time it sees an extrusion it turns the fan (and laser) back on. The script also pulls out the extrusion commands as it goes along and changes layer motion from lowering the build platform to raising it.

Thanks for the idea on the LED and for any comments you might have on the above as I am now unsure of my best direction!

Will

-

Figured that it was constant voltage. I want to be able to turn a laser on and off via g-code. Was hoping, since it will be connected to that power supply, that it would be switchable. I can make do by detecting when the fan is on and off and then trigger based on that...unless...you have a better idea?

The image should stick but will do gallery in the future. I thought the gallery was for pictures of things you care about! It seems the forum software could just take the upload and stash it somewhere!

-

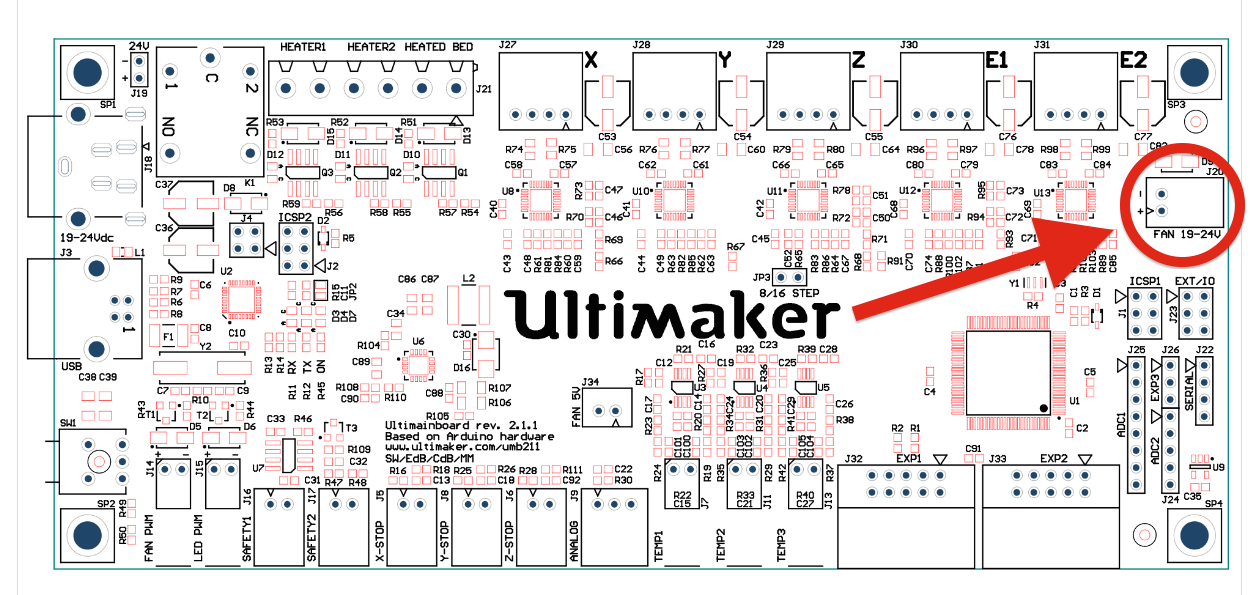

Sorry, I thought everyone would have the board memorized!

-

The Main Board has a fan connector labeled 19-24V that is unused on my UM2. It seems to be on by default. Is there a command to toggle it on and off?

-

Seems a little strange to take a website down during prime time in EMEA and during the morning in NA. Wouldn't a better time be on a weekend early in the morning? Or whenever your low-water point is?

-

Are there any signals already on the pins that are available on the Expansion Connectors? Obviously this being an open source environment I could go into the firmware and raise whatever signals I might want ... but this would take time and effort. In particular I am hoping that one of those pins goes to high when the extruder is active?

-

Unless your printer is in a temperature controlled room, and maybe on the warm side, a cover is essential for printing ABS (IMHO). It can help with printing anything that requires higher temperatures for the build platform as the warmup phase will be shorter than if the printer is open. I have two Ultimaker 2's recently upgraded to 2+'s and I have a cover for each of them:

After Market Cover for Ultimaker 2

I did the whole wrap the printer thing but gave it up as a bad job on multiple fronts not the least that it was ugly whereas the cover from Germany looks great. There may not be a huge fire hazard with the bag approach but anything that could get in the way of cooling the electronics is a bad thing and draping oven bags can easily do that.

I have thousands invested in my printers, paying an additional couple hundred for covers that looks as good as the printer seems like a good investment.

One note however. Obviously a cover is not needed for PLA and I had a number of occurrences of nozzle jams that I wonder might have been attributable to heat buildup under the cover. It seems that I had fewer jams when I did not have the cover on while printing PLA. With the UM2+ upgrade in place it seems this is not an issue as I am keeping the covers on all the time without issue. No scientific data to back one way or t'other.

-

I think you are right, either about belt tension or tension of the grub screws on your pulleys...

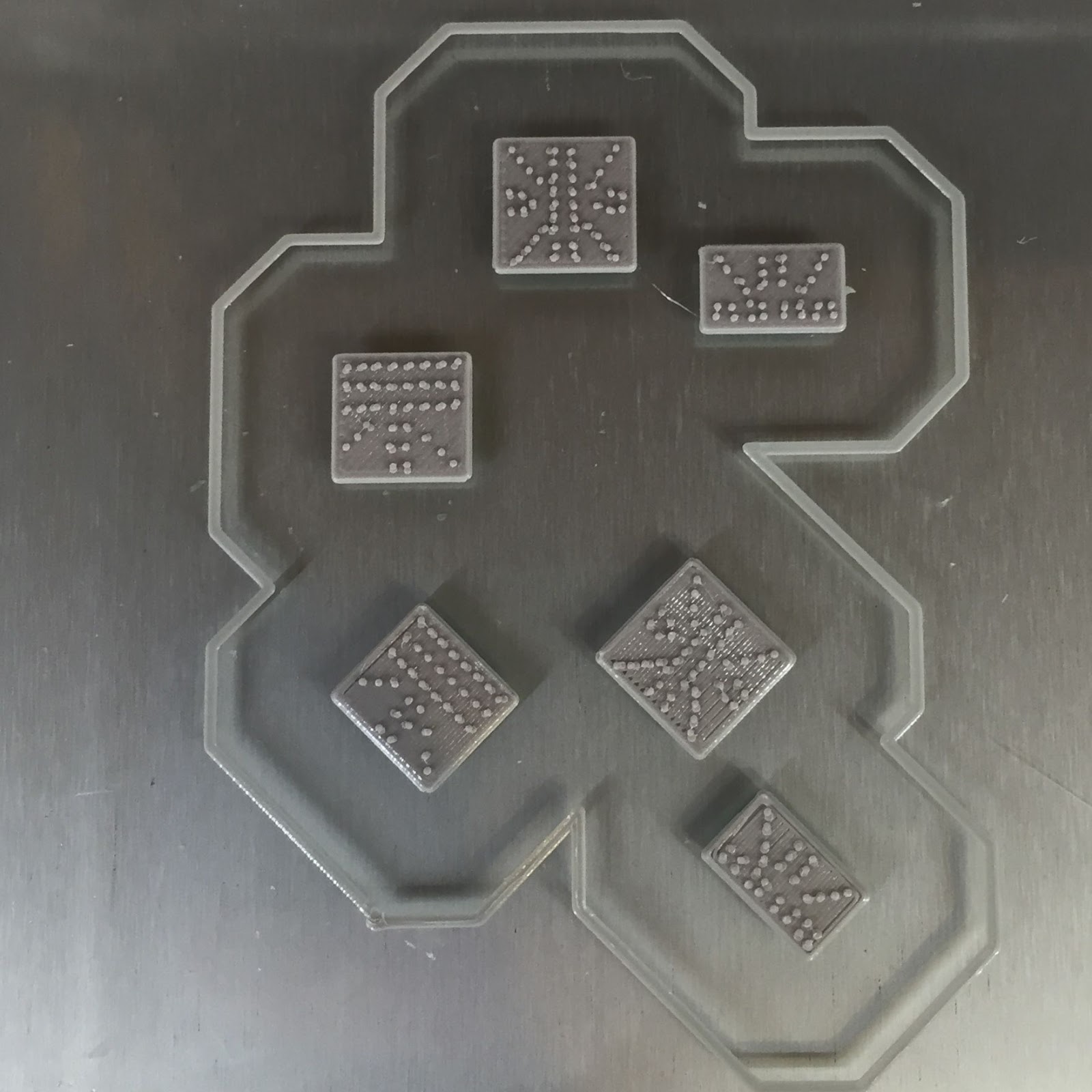

All those little dots...

...well, the little dots printed much better just by slowing down but even after letting the long belts adjust themselves, tightening all the grub screws, and making sure the short belts are nice and tight...I am still getting very obvious extrusion lines on the 45 degree rotated print but not on the normal one.

-

What do you use to stick your print?

I have two UM2+ printers and have had a Prusa I3 and a Makerbot Clone. I have tried virtually every possible technique for print adhesion across those printers. Interestingly what works on the UM2+ is different than what worked on the Makerbot Clone. But in any case...

What I have found as my general solution is a spray called 3DLAC. Until I found this stuff I was using hair spray for PLA and my fallback when that did not work was Klapton tape. Since I found 3DLAC it is used pretty much exclusively for PLA, Nylon, Co-Polymers, and specialty stuff like Colorfabb XT. The only thing that I have not gotten great results with is ABS where I still use Klapton tape. Two other notes on ABS ... I found that I needed to enclose my printers to be able to print ABS and I also find that it helps with some of the other higher temp filaments and I would also recommend an extra glass plate or two so that you can keep one covered in tape if you go that route.

Will

-

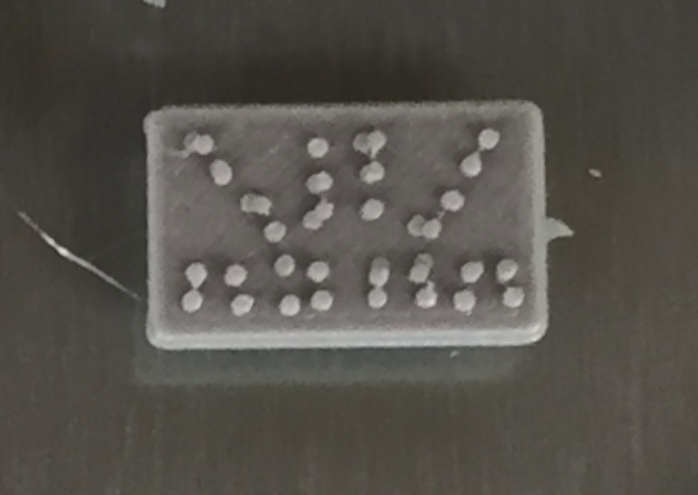

Every once in awhile something stumps me with my printers. This is a test print of some tiny little reinforcing panels for one of my bridge designs. The little dots are meant to be bolts or rivets. The print is done using a 250 micron nozzle and 125 micron layers in PLA. Simplify3D was the slicer. UM2+ the printer.

The panels printed at top, in normal orientation are fine, but the ones that are rotated by 45 degrees are not. I suspect this is a belt tension issue but am not sure! Any suggestions?

I am also a little curious as to why my second layer of dots seems to show some of them shifting?

-

Didn't see any obvious change to a print after lubrication, maybe my |Robert| feeder is doing its stuff.

My environment is pretty dusty which may have contributed to friction in the bowden tube but the impact for me was profound (as you can see from the picture at the start of the thread). If you can feel a smoother feed then I would suggest that somewhere down the road you will avoid some under extrusion!

-

I did not have great success with burning nozzles. They turn black and occasionally lose a few black specks of dust while printing which is not that useful...

I have not had the specks issue and I have done a dozen or so nozzles....nor have my nozzles turned black.... How hot do you get them? I take mine up to glowing and keep them there until they look "clean" (5-10 seconds past glowing). When they cool down they are uniformly grey. I use a creme brûlée torch from the kitchen and it works a charm. I do try to let the plastic inside the nozzle run out when I first start to torch em.

-

But I know exactly what you guys mean. Over the top. Crass. Jokes not funny. But that covers up a genuinely kind person. He's quite smart also and somehow finds patience when alone.

Funny that you should know him in person. As with all things that you post I will bow to your knowledge on the topic of him being a top tomato. :-o As a casual bystander I wonder if he would have more viewers if he kept up the great work on content but maybe rebranded himself a little...? But you do have to be true to yourself and maybe his followers that he has today would bail on a more boring version of himself? BTW, I can very personally appreciate the comment on playing through pain.

-

Just put it in a flame and burn the hell out of anything in there. Or throw the nozzle away (I have never had to throw away a nozzle yet).

Interesting. I was going to ask about torching nozzles but was not sure the reaction that I would get (like...WHAT ARE YOU NUTS!?!?). I still to cold pulls as I think they help the boundary area between the nozzle and the coupler but once in a while I have been known to torch a nozzle until it is glowing hot. Seems to cure all evils. Was wondering about the impact of de-tempering though I assume this would take quite a few torchings to have an impact? Or does temper even matter with a nozzle?

-

Interesting that I had recently seen Barnacules Nerdgasm had a video episode on this.

I had also stumbled upon this guy and this video, I don't remember how.

His filter concept may need a bit of refining, but I like the simplicity of the basic idea. And for sure silicone oil does not get ransic like vegetable oil, which might become a tough mess over time. And it doesn't seem to make the filament slip in the feeder either (which is a bit surprising to me).

And if you use Windows 10, also have a look at his videos concerning the creepy privacy issues; it is very well explained.

Here is a picture of the dust filter / lubricator that I am using. Pretty simple, quick print, that looks nice hanging on the back of my expensive printers!

Here is a picture of the dust filter / lubricator that I am using. Pretty simple, quick print, that looks nice hanging on the back of my expensive printers! Maybe it is because I am a yank living in the UK but I am sensitive to the stereotypes that occur to people when the think about an American...and Barnacules Nerdgasm hits the majors: Too loud, too large, and too over the top! Regardless of the quality of his content it pains me to watch his delivery!

-

Interesting that I had recently seen Barnacules Nerdgasm had a video episode on this.

I find the guy hugely obnoxious but he is right about the difference this can make. Not sure why he felt the need to cobble a filter together when there are dozens to choose from that can be printed!

In any case, he is focused on the dust aspect until the end where he mentions the benefit of lubrication. It might be a combination of both but I think the lubrication is the bigger benefit.

-

I did a rudimentary strength test with results that while contestable in terms of them being "apples to apples" would still indicate that strength is not an issue. The test was not apples to apples for two reasons, first that I can only base my before strengths on data collected months ago, and second because the test prints I used back then look like they might have suffered from a wee bit of under extrusion themselves! So, when I printed two new test pieces and put them to the test one destructed at 17.59kg and the other lifted my desk off the floor so I gave up. In my original test the break point average was 14.3kg. Whether apples to apples or not I am satisfied that strength is not an issue!

BTW, here is a link to the dust filter that I am using. Obviously there can only be a little oil entering the system.

-

I have added oil when printing ninjaflex and it doesn't seem to affect the print quality. It certainly looks great but is it weaker? I don't know. I don't think it hurts anything. I think the oil stays apart (ends up mostly on the outside of the print) from the print. But I don't know. I have a stress/strain analyzer machine. So one of the things I will test is prints with and without oil to see if this affects flexibility or strength of the printed part. Some day.

Thanks gr5, I was going to tag you for an opinion but you beat me to it. I will do my rudimentary stress test today. The amount of residual oil ending up coming through the nozzle has be pretty tiny so I would be surprised if there was a difference. Of course both of my printers are now filtered so my baseline will have to be the data from a heat related test that I did some months ago. Not the best scientific method!

I am just amazed at the difference that it has made,

Will

-

I my mind it just feels so wrong to add a oil into the extrusion system, i am no polymer chemist, but that added oil has to go somewhere, and extra oil in the plastic will probably make for less layer adhesion etc...

That is why I am asking! It does seem like it could be problematic but the prints that I have done to this point, and there have been quite a few, show no issues as of yet. I have a layer adhesion test that I will try to do today or tomorrow but based on my observations to date I don't expect to see a difference from when I did it some months ago.

Hopefully someone that is a polymer chemist will chime in!

Will

-

I have two Ultimaker 2+ (upgraded from 2's) that I have been running for 18 months. Prior to these printers I had built a Prusa I3 and had a Makerbot Clone.

My number 1 recurring issue on my Ultimakers always seems to come back to extrusion. I do a lot of atomic cleans, I regularly replace the teflon coupler, I keep the extruder gear clean, and with the advent of removable nozzles, I change nozzles a lot.

What I have not done until recently is lubricate the bowden tube. I did replace them with more slippery versions prior to the "+" upgrade which of course did come with new tubes.

The "+" upgrade certainly improved extrusion. Startups are much more reliable without my attention (prior to the upgrade I often manually primed the nozzle just to be sure of a good startup).

Recently, however, my "+"'s have started to sputter a little on the extrusion front. Having done all of the normal things that I have been doing I looked for something new that I have not tried and came across a suggestion to lubricate the bowden tube. This suggestion was made on the 3D Hubs forum and since I had not seen it on the Ultimaker Forum I did a couple of searches and did find some references suggesting the use of dust filters that also lubricate. The feedback was very mixed with recommendations that you not lubricate stuff going into the feeder.

I had used a filament cleaner on my Makerbot Clone and it did not seem to hurt so I decided to go ahead and try it on my Ultimakers. The results have been profound (in a good way). The only difference between the failed print, due to under extrusion, on the left and the near perfect print on the right was the addition of a filament filter that also lubricates:

The questions this leaves me with are:

First, is there a reason that I should NOT be doing this (as in will I see some long term harm)?

Second, what lubricant should I be using (right now I am using a high smoke-point temperature nut oil)?

As I mentioned, I am now doing this on both of my printers and am really happy with the result though I have had to adjust my profiles to lower my extrusion adjustments as compensation for stuff getting to the nozzle more easily!

I do question myself as to why I have not done this before and wonder if my extrusion issues have been threshold related. Meaning that I start to see issues at a certain threshold of resistance. Say that "R" is resistance and R=100 is the point where problems start to occur. Say that changing a nozzle gives you a benefit of -10, an atomic clean might add a little to that as it may also clean the boundary between the nozzle and the teflon coupler so maybe a -15 with a nozzle change. Changing the teflon coupler gives you another boost, maybe a -30, depending on how bad it was. In the meantime, however, the bowden tube has been adding resistance. Say a +5 every month. Once you hit the 100 you can improve things with nozzle changes, atomic cleans, and new teflon couplers, but the inexorable creep of resistance building inside the bowden tube will ultimately take you to the threshold and beyond. Enter lubrication?

So...am I making any sense? Why is lubricating the bowden tube not a more popular suggestion? Thanks for listening!

-

Thanks. It is working again but I will bookmark this for when it quits!

-

Pressing the thumbwheel on one of my printers no longer works! It stopped mid print and I only found out when I went to cancel the darn thing. I have not pulled the printer apart yet but wondered if this is common? I assume the thumbwheel is a sealed unit and the issue is not debris?

Thanks,

Wisar

Enclosure

in Third party products & modifications

Posted

Speaking of enclosures...I wonder what the dimensions of the Ultimaker 3 are going to be. I suspect that I will need a new enclosure!