DidierKlein 729

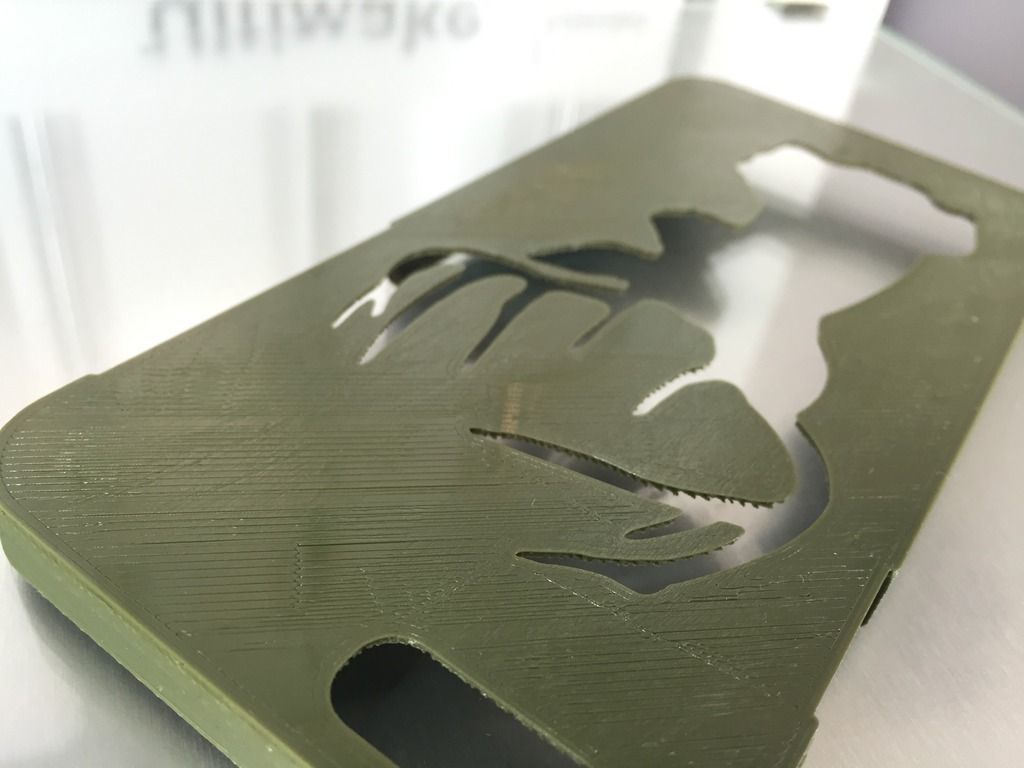

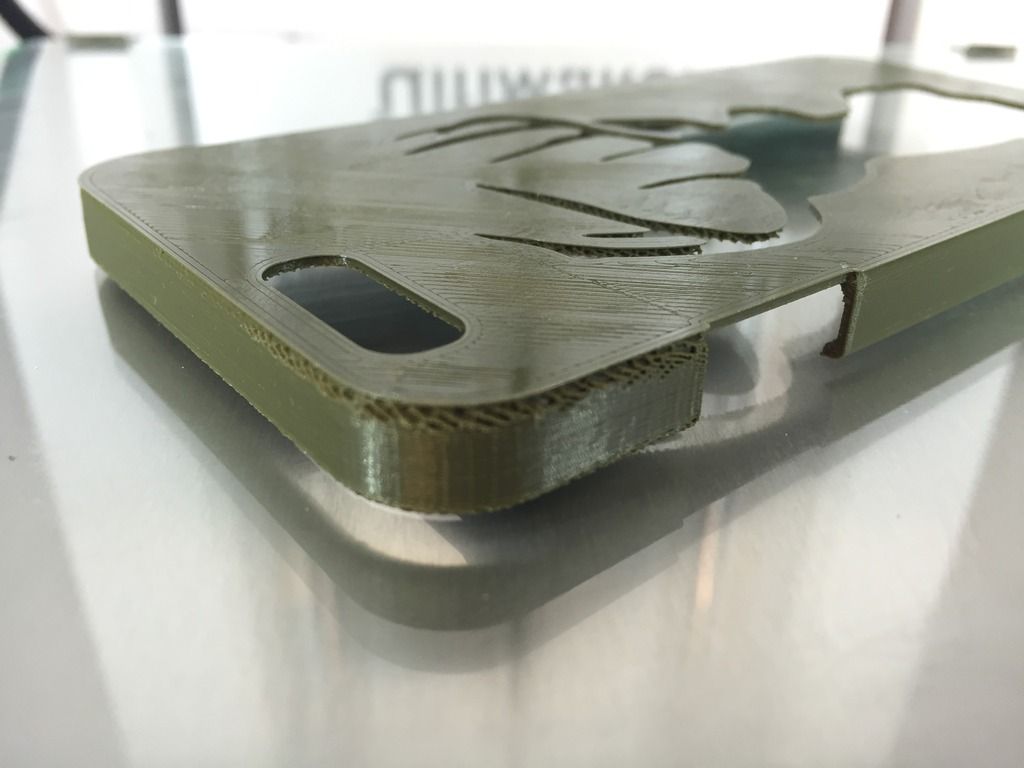

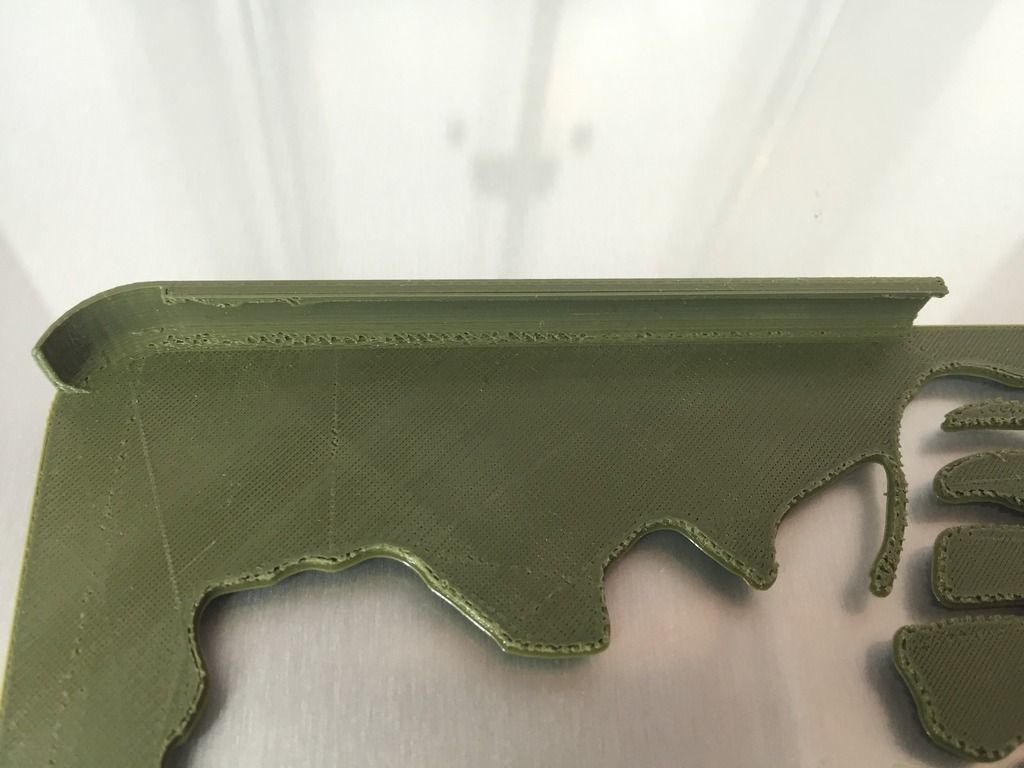

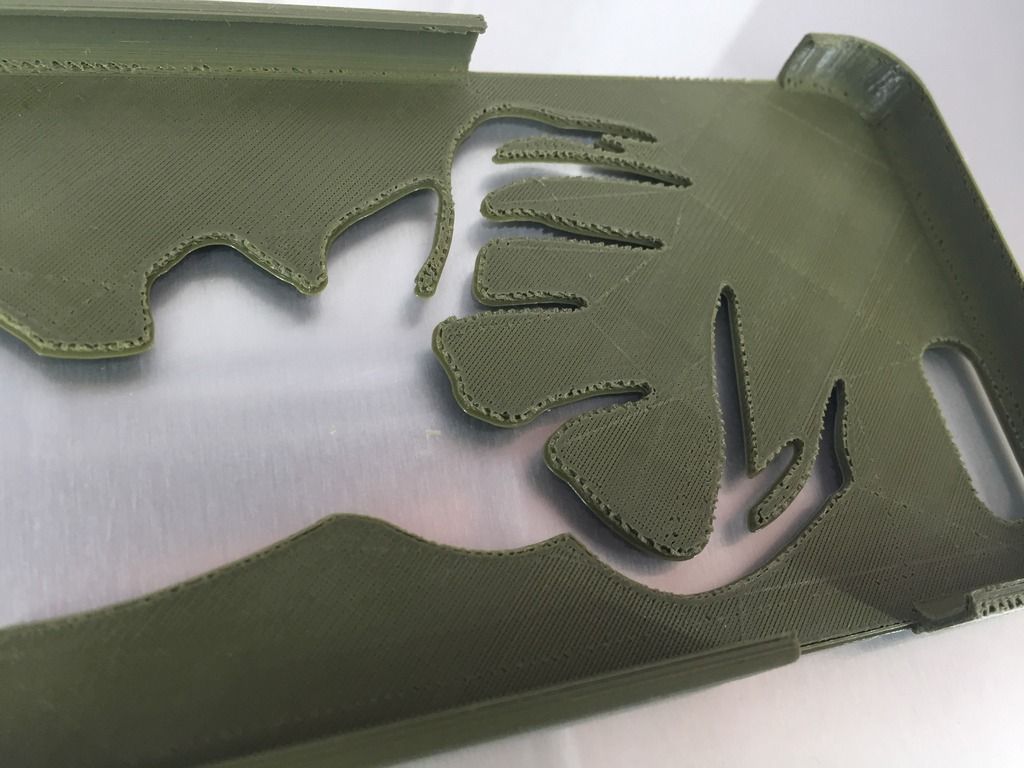

You have some underextrusion on some parts.

What is the brand and size of the filament?

This is ColorFabb PLA/PHA 2,85mm

DidierKlein 729

Maybe to cold and/or too fast

I've printed this at 228 degrees which is warmer than they suggest (max. 220 deg) and the speed was max. 50 mm/s, is that too fast for something like this?

Anyways, I'll do some more testing with this. I've also printed a little robot with this color which was a fail as well. :(

how old is the printer and have you ever replaced the PTFE coupler and/or performed a hot/cold pull?

Hi Korneel,

The printer is one month old, did not replace the PTFE coupler yet (since it's still pretty new). By hot/cold, you mean the "atomic method"? I did that once to test it out, using ABS.

well, you can still wreck it within the month ![]()

when you start the print, do you get a very nice ice cone shape on the front left?

it is at 8 minutes and 50 seconds

this is exactly how it should look like, a nice upside down softice that is being pushed out..

does it do the same thing for you?

Edited by GuestOr the PTFE coupler is not good or there is a small blockade in the nozzle. Be carefull changing from ABS to PLA. Try some "atomic pulls" with PLA and check how dirty your filament is that you pulled. The in print of the nozzle should be in there.

Or the PTFE coupler is not good or there is a small blockade in the nozzle. Be carefull changing from ABS to PLA. Try some "atomic pulls" with PLA and check how dirty your filament is that you pulled. The in print of the nozzle should be in there.

i would say, please don't do atomic pulls with PLA or ABS.. you can't really clean the nozzle with it and it'll break when force is applied. please use Nylon for this...

Or the PTFE coupler is not good or there is a small blockade in the nozzle. Be carefull changing from ABS to PLA. Try some "atomic pulls" with PLA and check how dirty your filament is that you pulled. The in print of the nozzle should be in there.

i would say, please don't do atomic pulls with PLA or ABS.. you can't really clean the nozzle with it and it'll break when force is applied. please use Nylon for this...

I hear more people praise Nylon, so I guess that works too.

But I think PLA has also proven to work, so if you don't have any Nylon PLA could be a second best.

Have you also printed with ABS?

Did you clean the nozzle afterwards?

By doing an Atomic Method using ABS you might have made the nozzle 'dirtier' by leaving ABS residue in the nozzle. That can interfere with a nice and smooth material flow when doing a PLA print later.

Here is a guide towards Atomic Method

Yes I do, in fact I'm getting some really nice prints with some materials. but sometimes it's all messed up, haven't figured out why yet.

I was not thinking of the printer itself although I had some minor issues and also the LCD flickers since the beginning I had it but don't know if that's normal.

See:

well, you can still wreck it within the month

when you start the print, do you get a very nice ice cone shape on the front left?

it is at 8 minutes and 50 seconds

this is exactly how it should look like, a nice upside down softice that is being pushed out..

does it do the same thing for you?

so if you get a good cone, and it's important to have an automatic round shape and the flow should be very consistent, that means at least your feeder is working well and the PTFE is not deformed and your nozzle is ok.

so that's good news!

then it's down to temperature playing..

what is the speed you are using, the material, and the temperature and the layer height?

Recommended Posts

DidierKlein 729

On the purple one the holes are due to low infill or top/bottom layers value being to low.

Try to have at least 6 layers at the top.

For something small and flat like that i usually fill it completely (infill 100%) or top and bottom height to match the height of the print.

Link to post

Share on other sites