Perfect! Thank you for your quick reply!! This forum is great.

-

1

1

Perfect! Thank you for your quick reply!! This forum is great.

1

1

Conductive filament has a conductive element admixed. Such admixtures (powder, fibres etc.) are quite abrasive. I would indeed recommend a special nozzle but avoid maybe steel or similar and go for a ruby nozzle, e.g. the Olsson Ruby.

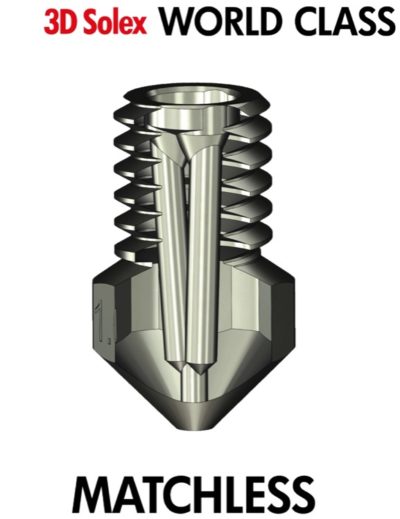

You may also like to take a look at http://3dsolex.com/ specifically the Matchless nozzles which have special internal design to improve materiel flow and there are options with ruby/saphire tips for printing abrasive materiels. I have three different sizes of these hard tip (called 'Everlast') nozzled and am very impressed with them

good luck

That is really neat...What a crazy internal geometery!!

Image for the lazy:

The idea of the "crazy internal geometry" is that there is more contact area between the hot nozzle and the material. If you visualize one thicker channel of molten material, you might imagine it is harder for the heat to get to the center of that channel.

That is really neat...What a crazy internal geometry!!

my experience is that you can (and should) print with a lower temperature using this nozzle

It just works really well

Nice! I have bought one and am very excited to try it out!!

Recommended Posts

Dim3nsioneer 557

Conductive filament has a conductive element admixed. Such admixtures (powder, fibres etc.) are quite abrasive. I would indeed recommend a special nozzle but avoid maybe steel or similar and go for a ruby nozzle, e.g. the Olsson Ruby.

Edited by GuestLink to post

Share on other sites