Yeah I had the same issues 2 days ago, some parts were just not getting enough fill. The feeding mechanism was making cracking sounds, so I checked it out. Turns out I actually had some screws in the feeding mechanism way too tight, causing the wheel (with the bearing in it) to not being able to move. Eventually I loosened up that part, and made sure the feeder screw was nice and tight (but not too tight ofcourse)

I think you should first check your feeding mechanism, do a test print, and see if the filament sometimes stops going into the extruder. Once your feeder is okay, check your filament diameter in Cura, and maybe set the flow% to 110 percent to see if that helps.

Good luck!

Recommended Posts

gr5 2,210

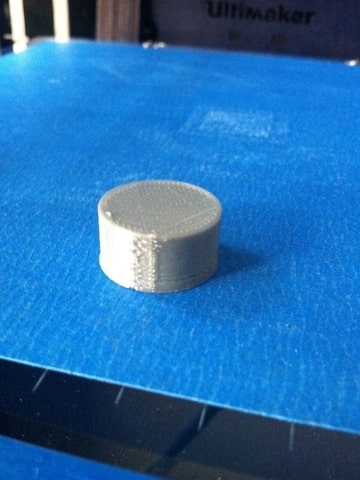

That last picture - that's pretty bad.

I can see that your belts are loose as you can see there are two lines close together followed by a gap, then two lines again. This is probably due to the short belts being loose. Here is an explanation:

http://umforum.ultimaker.com/index.php?/topic/1872-some-calibration-photographs/?p=14474

However, that's not the main problem. There is not enough filament getting laid in there. Strange. Is the feeder screw tight? It should be compressed to about 11 to 11.5 mm. The feeder should be able to pull about 22 pounds force with no load (no pressure) at the print head. You might want to test this by pulling back on the filament.

You could increase "flow" at the UC. Not sure this is a good solution. Could it be that you set the filament diameter to 3mm in cura yet your actual filament diameter is less - around 3.9mm? This would only reduce infill by 2.5% yet you appear to have 50% underfill.

Maybe your nozzle got clogged near the end of the print? Some dust or wood chips might have gotten in there.

Maybe you don't have the fan on? With the fan off, sometimes the nozzle messes up the layer below because it hasn't had time to harden.

That's all I can think of. It sure looks strange. Like the feeder stopped feeding filament. Or the nozzle got jammed.

Link to post

Share on other sites