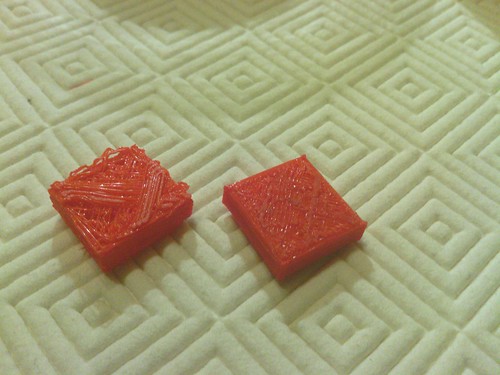

With SkeinPyPy your settings should be right. So that's not it. You have serious under-extrusion. Most likely your filament is slipping. They look a lot like my first prints, which also had slipping problems.

Make sure your tension knob is tight enough.

Make sure your big gear is firmly attached to the bolt. (This was my problem)

Recommended Posts

mr_seeker 0

I use slic3r, and I use the following settings:

If you can print with these settings, then I am sure you can get a good and decent print

Onliest thing you need to change is the layer height. I could get up to 0.015, but then you manually need to make it stick to the bed. 0.05 is usually enough for high-quality prints. Note that it doesnt prevent it from stringing.

If you use skeinforge, try printing with the profiles that came with the repG software. They should work properly.

Link to post

Share on other sites