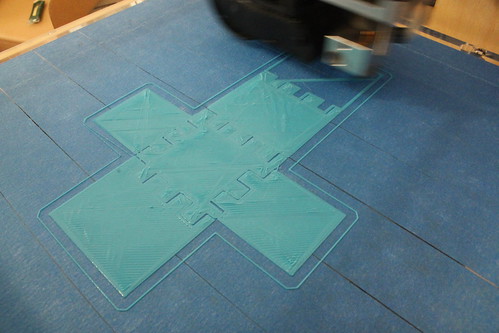

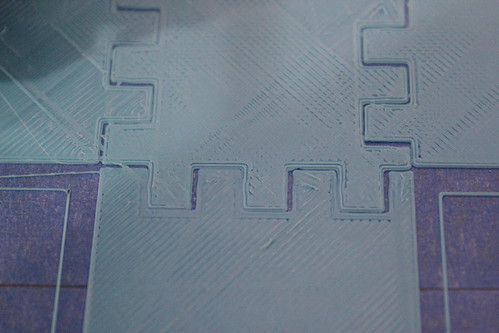

That's a tricky print. Just looking at it quick with my 3AM eyes that _really_ want to go to sleep it looks to me like retraction isn't happening due to the very small distances between the leafs (or simply not working all that well). You could try decreasing the minimum distance for retractions if that's the case but i wonder if the filament will hold up to that many retractions.

I'll take another look tomorrow when my brain is functioning, unless the Americans can tear themselves away from the turkeys before then ![]()

Recommended Posts

david-lawson 0

No modifications to the setup, normal quality print of the ultimaker robot:

Link to post

Share on other sites