I

1 hour ago, gr5 said:You can't iron the bottom layer without flipping the part over, right? I'm confused.

By default, most profiles have combing set to "all". Change "combing mode" to "not in skin" and that should make your bottom layer look much better.

I understand that ironing should only work on top layers, but since it is effectively forcing a small amount of extra filament into the previous layer, would this not also force filament into a first layer, reheating it and perhaps helping to smooth out the first layer against the glass to produce an entirely flat first layer with little evidence of lines remaining?

I will take a look at the combing settings anyway and see if that improves things.

Thanks for the tip.

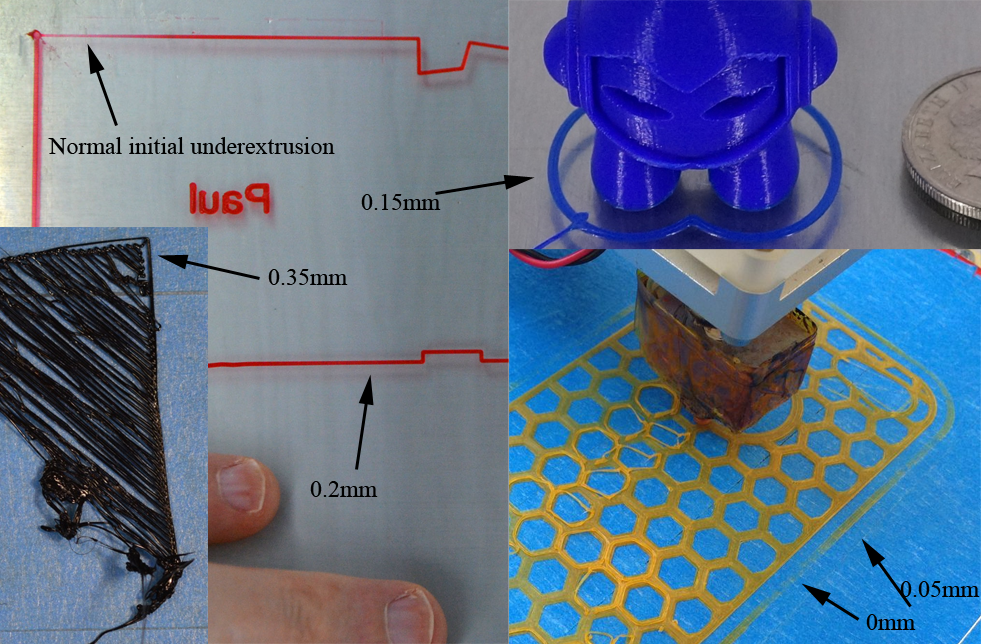

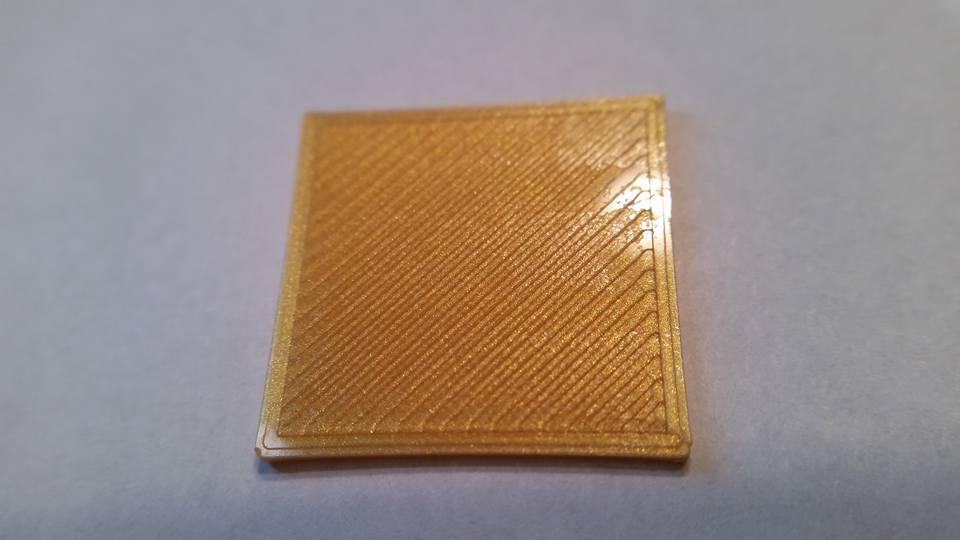

. here are some photos of perfect bottom layer squish amounts:

. here are some photos of perfect bottom layer squish amounts:

Recommended Posts

gr5 2,210

You can't iron the bottom layer without flipping the part over, right? I'm confused.

By default, most profiles have combing set to "all". Change "combing mode" to "not in skin" and that should make your bottom layer look much better.

Link to post

Share on other sites